Graphene vaccines are a weapon of genocide

Green Berets The Super Vaccination Program is being implemented around the world with the help of the biological weapons of genocide disguised as COVID-19 vaccines.

Alas, we must state the obvious: Covid "vaccines" are not vaccines at all; they were never meant to do that.

Each Injection of BigPharm was designed as a very sophisticated biological weapon designed to kill, weaken, disease, incapacitate and/or maim unfortunate victims.

To date, all scientific, unconfirmed and circumstantial evidence clearly points to a carefully developed bioengineered vaccine against false Covid, which is imposed on humanity with the aim of establishing a totalitarian digital dictatorship and depopulation of the planet.

In Stockholm, the winners of the Nobel Prize in Physics for 2010 were announced. They were Russian physicists from the University of Manchester Andrei Geim and Konstantin Novoselov. Their main invention is a material called graphene. What is graphene and how can it be used?

A transparent blue stripe on the table works as an alarm clock. It also shows the schedule for the day, in the car it unfolds into the screen of the navigator, at work it turns into a laptop, and in the evening you can watch a movie on it. And you can charge this super conductor in an injection, mask, smear and generally anywhere. What did the terrorists of the special operation Corona 👑

Thomson Reuters found graphene worthy. The list of probable laureates included Novoselov and his head - Andrei Geim, director of the Center for Mesoscopic Physics at the University of Manchester.

The super material was obtained with sticky tape that didn't accidentally get into the trash.

Graphene is a layer of carbon one atom thick. Billions of such layers form graphite, from which pencil slates are made. No one believed in the possibility of separating one layer. Seventy years ago, Lev Landau and Rudolf Peierls proved that such materials could not exist: the forces of interaction between atoms must crudge them into an accordion or roll them into a tube.

Graphene was an exception to this rule. Geim and Novoselov drew attention to the usual tape, with the help of which graphite samples are prepared to work on a scanning tunnel microscope. Scotch tears off the graphite layers, leaving an absolutely smooth surface. The tape is thrown away along with what sticks to it. "For the fact that we picked it up and researched it, we were called garbage scientists — garbage scientists," laughs Novoselov. By gluing and sculpting a tape with flakes of graphite several times, Novoselov received what was considered impossible - layers of graphite one atom thick. Their area reached one square millimeter: this is more than enough to transfer graphene to the substrate and explore the mechanical and electronic properties. In 2004, the journal Science published a landmark article by Geim, Novoselov and their longtime colleague Sergey Morozov. The properties — conductivity, strength, stability — were unique.

"Graphene has properties that no material has," Novoselov said, "it's literally matter, fabric. With it you can do the same thing as with this napkin: bend, roll, stretch ..." A paper napkin suddenly bursts in his hands. With graphene, this will not happen, the physicist notes, it is the most durable material on Earth.

Electrons in graphene move a hundred times faster than in silicon. In that year, 2010, Geim and Novoselov et al. showed that graphene could be used to make transistors controlled by individual electrons. All this made it possible to create what we all know today - miniature and fast chips, which are heated much less than silicon.

Representatives of different companies appealed to them, Geim and Novoselov sent buyers to Graphene Industries, a firm created by their students. Those manually made then graphene plates and sold by the piece in the laboratory of IBM, Intel, Samsung.

For example, ultrafast high-frequency transistors used graphene for receivers and transmitters of mobile communications. Especially advanced in their creation ibm and HRL (close to the defense order research laboratories, which are jointly owned by Boeing and General Motors). HrL later received a grant for a 50-month graphene electronics program coordinated by SPAWAR, the U.S. Navy's engineering center. They don't even pretend to be doing physics, but say outright what they're making devices.

The development of the graphene theme attracted the attention of private investors. Several U.S. companies had ventured into producing hundreds of tons of graphene by the end of 2010.

The carafe is in demand as a filler for composite materials, said the general director of XG Sciences Michael Knox. The CEO of Angstron Materials Bor Jang proposed to use graphene in energy storage devices - batteries and supercapacitors, as well as fuel cells that generate electricity from the combination of hydrogen with oxygen. Vorbeck Materials sells Vor-ink, the "ink" that allows you to print electronic circuits.

Knox learned about graphene in 2006 from University of Michigan professor Lawrence Drzal, who convinced him that graphene could make good money. "I just sold my previous business and was looking for some promising technology," Knox recalls. "Since then, the hype around graphene has been growing steadily."

Jang is an example of a scientist-entrepreneur, as if descended from the pages of a brochure on the commercialization of technologies. Since 2005, he has been dean of the College of Technical and Computer Science at Wright University. The launch of his company Nanotek Instruments in 1997 was provided by grants from the US Department of Energy. Then Angstron sped away from Nanotek. His first patent related to graphene, Jang announced in 2002 - two years before the revolutionary work of Russian physicists. "Their merit is that they were the first to discover the unusual electronic properties of isolated sheets of graphene," explains Jang. By 2015, he modestly planned to occupy 30-40% of the global graphene market, and even earlier - to conduct an IPO or sell the company to a large investor. Vorbeck has acquired a serious partner: for the German chemical giant BASF, the company is developing conductive paint.

For a fundamental discovery to be put into practice, it must be made up of thousands of inventions. From the creation of the first transistor in 1947 to the spread of integrated circuits, which provided the primacy of silicon electronics, it took almost two decades. The graphene revolution went its well-troded way ... Like the atomic bomb in its time...

And although we have already covered this delicate and inconvenient moment for the global kahal, as well as many other delicate and inconvenient moments, as a reminder, we remind you once again:

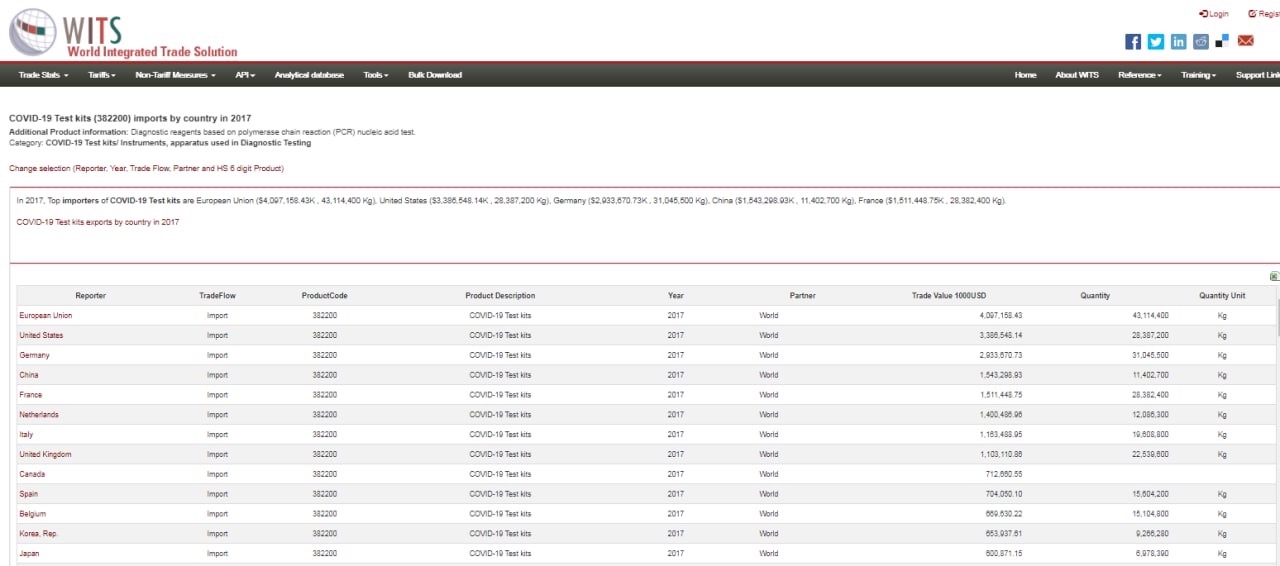

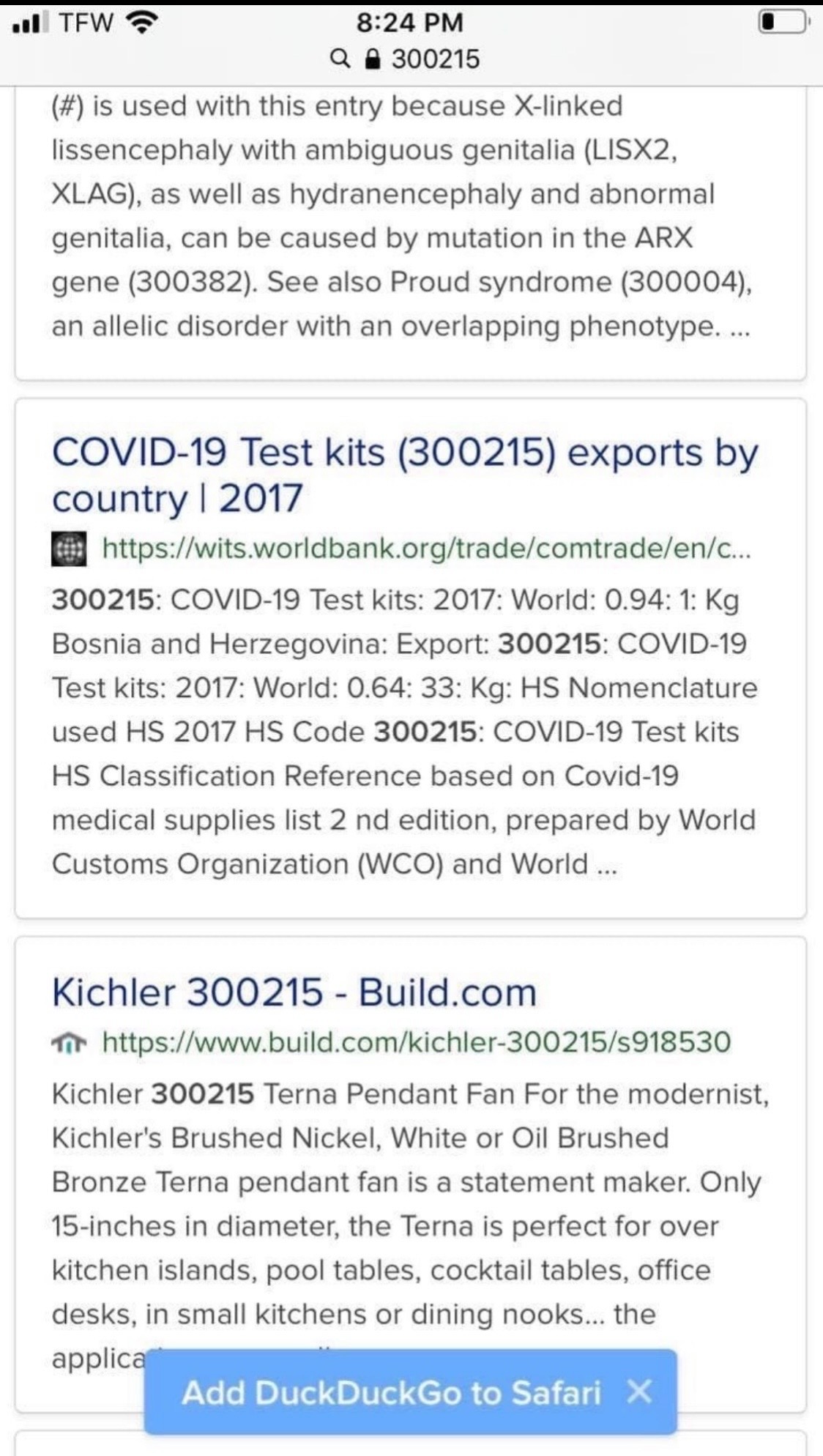

Imports of COVID-19 testing kits (382200) by country were carried out back in 2017, when no one had heard of covid yet.

"Additional product information: Diagnostic reagents based on the nucleic acid polymerase chain reaction (PCR) test.

Category: COVID-19 Testing Kits / Tools, Diagnostic Testing Equipment".

In 2017, the main importers of test kits for #COVID19 steel

EU- amount: $ 4 097 158, 43 thousand, quantity: 43114400 kg,

US $ 3 386 548, 14 thousand; 28387200kg,

Germany $2,933,670,73,000; 31045500kg,

China $1,543,298.93,000; 11402700 kg,

France ($1,511,448.75,000; $28,382,400).

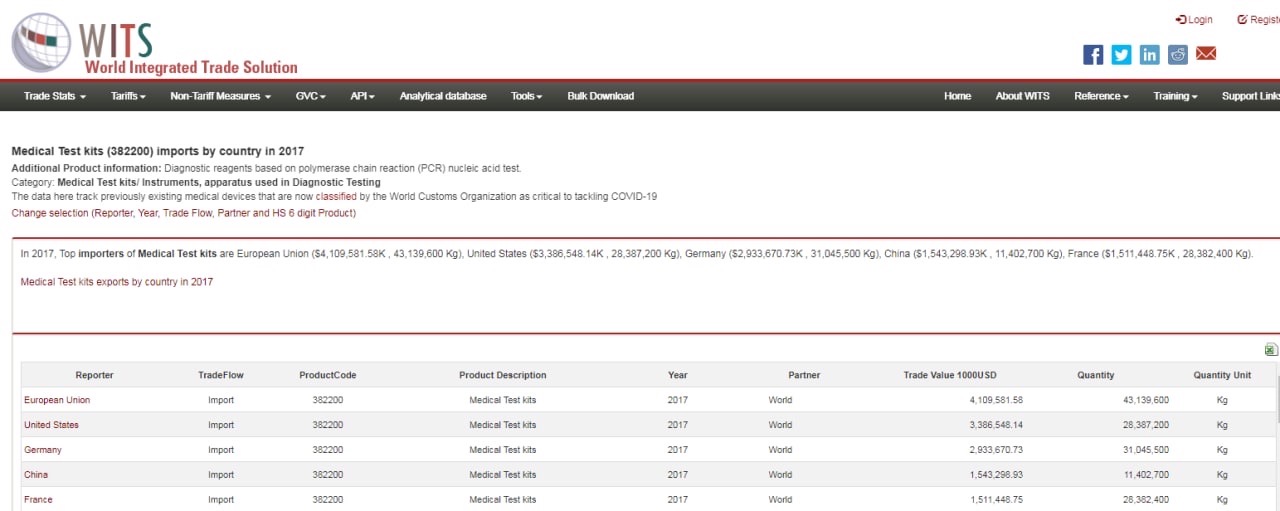

Meanwhile, when information that Covid test kits were sold back in 2017 hit social media and triggered a number of uncomfortable questions for BigPharma and the WHO's interests, the page was redesigned and the COVID-19 test kits were called Medical Test kits.

On the grounds for lockdown of Komsomolskaya Pravda Ani

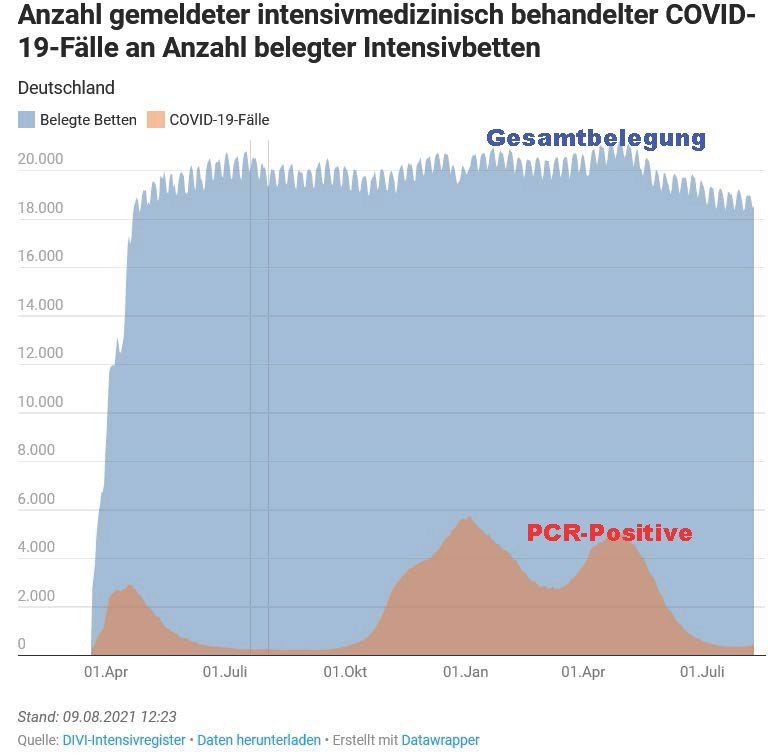

Here is a graph of the number of occupied intensive care beds from April 1, 2020 to August 9, 2021.

It's funny that testing doesn't correlate at all with the total number of beds occupied. The orange bars are PCR positive, and the blue ones are the total number of beds occupied.

We see a simple change in structure, and the label "positive on fake-19", which does not carry any changes in the overall load. And it's just pure fraud.

https://telegra.ph/MADE-IN-RUSSIA--BIOCHIP-FROM-GRAPHENE-OXIDE-07-08

Yes, and it is these grounds that the Komsomol Merkel, in agreement with Putin, has to close the Germans in Germany for lockdown.

Nobody writes to the colonel

https://telegra.ph/GRAPHENE-OXIDE-IN-COVID-VACCINES--19-07-08

https://telegra.ph/ApolloSoyuz-Test-Project-ASTP-20-07-08

Big cities

Empty trains

Neither shore nor bottom

Start all over again

Cold war

And time is like water

He didn't go crazy.

You didn't know anything

Nobody writes to the Colonel Nobody Is Waiting for the Colonel

In the line of fire

Empty Cities

In which never

You've never been before

And the trains are torn

On subtle words

He didn't go crazy.

You didn't know anything

Colonel no one writes Colonel no one is waiting for the Colonel no one writes Colonel no one is waiting for the Colonel no one writes Colonel no one is waiting

Drawing ✍️ graphene on the writings of neo Marx Schwab and a modern Russian concentration camp. Russian partisans sent us information, Russian patent for graphene is here

https://telegra.ph/GLOBAL-KOGAL-CREATE-ARTIFICIAL-HUNGER-Agro-terrorism-08-10

https://telegra.ph/UNDER-PHILOPHIPH-DAVIDS-TIME--MACHINE-08-10

https://telegra.ph/Biological-Terrorist-Number-1-08-11

METHOD FOR PRODUCING GRAPHENE

(nineteen)

RU

(eleven)

2 632 688

(13)

C1

(51)

IPC

C01B 32/19 (2017.01)

B82Y 40/00 (2011.01)

B82B 3/00 (2006.01)

(21) (22)

Application:

2016143665, 2016.11.07

(24)

Start Date of Patent Term Report: 2016.11.07

(22)

Application date: 2016.11.07

(45)

Published: 2017.10.09

(72)

Authors:

Zhebelev Sergey Ivanovich (RU)

(73)

Patent holders:

Zhebelev Sergey Ivanovich (RU)

(56)

Documents cited in the search report:

FRANCESCO BONACCORSO et al.

Production and processing of graphene and 2d crystals, Materalstoday, 2012, v. 15, N 12, p.

564-589.

RU 2570069 C1, 10.12.2015.

US 2013/0102084 A1, 25.04.2013.

WO 2011/055039 A1, 12.05.2011.

A. V. Yeletsky

and etc.

Graphene: production methods and thermophysical properties, Uspekhi fizicheskikh nauk, 2011, vol.

181, N.

3, p.

234-268.

abstract

The invention can be used in nanoelectronics. The graphite particles are placed in a vacuum between the electrodes, while the potential difference is set sufficient for the electrodynamic liquefaction of the particles and for them to obtain energy exceeding the work required to split them along the cleavage planes into graphene layers during brittle destruction during impacts on the electrodes. Graphite is used with a density of 2.3 · 103 kg / m3, the particles of which are less than 1 mm in size. The invention improves the productivity of obtaining high-purity graphene. 1 wp f-ly.

Claim

1. A method of producing graphene by stratification of graphite in vacuum, characterized in that to obtain graphene, graphite particles are used, which are subjected to electrodynamic liquefaction between the electrodes, the potential difference of which is set sufficient for their electrodynamic liquefaction and the receipt of energy by the particles when they move between the electrodes, exceeding the work required to split particles along cleavage planes when they hit the electrodes.

2. A method according to claim 1, characterized in that graphite particles are used with a size of less than 1 mm and a density of 2.3⋅103 kg / m3.

Description

The invention relates to the production of carbon nanomaterials, such as graphene, and can be used to produce graphene for use in nanoelectronics.

All currently known methods of obtaining graphene are long and expensive with a low yield of graphene (Eletskiy A.V., Iskandarova I.M., Knizhnik A.A. et al. Graphene: methods of obtaining and thermophysical properties. Uspekhi fizicheskikh nauk, 2011 , t. 181, No. 3, p. 233-250).

A known method of forming graphene by stratification of graphite (see patent US 20130102084 A1, IPC С01В 31/04, H01L 51/00, H01L 51/42, publ .: 04/25/2013), combining a number of options involving the introduction into the space between atomic layers a graphite sample of solutions of metal salts (Li, Al, Fe, Cu) in organic solvents (propylene carbonate, N, N-dimethylformamide, dimethyl sulfoxide). Ions and organic solvent molecules expand the space between the atomic layers, which makes it possible to separate them when exposed to an external driving force, which can be of an electrochemical, thermal, microwave, solvothermal, acoustochemical, or acoustic nature.

The disadvantage of this method is low productivity due to the long duration of the stages of its implementation.

Closest to the claimed technical solution is a method of obtaining graphene particles or flakes by abrasion of solid graphite on a rough rough surface, for example, on a glass surface having a roughness from 0.01 to 10 pm. During friction, graphite is transferred to a rough surface, leaving traces, which are graphene material. The specified surface is then subjected to sonication to separate the graphene material from it (WO 2011055039, cl. B82Y 30/00, 2011).

The disadvantage of this method is its low productivity, because The method requires constant interruption of the process to separate graphene layers from the abraded surface to restore roughness and continue the abrasion process of solid graphite.

The problem to be solved by the claimed invention is to increase the productivity of the process of obtaining carbon nanomaterials, in particular graphene.

This problem is solved due to the fact that the claimed method of producing graphene by exfoliating graphite differs in that the graphite particles are subjected to electrodynamic liquefaction in a vacuum, in which the energy of the graphite particles exceeds the work required to split them when the particles hit the electrodes.

The technical result provided by the above set of features is to increase the productivity of the graphene production process.

The essence of the invention is as follows.

In the proposed method for producing graphene, the process is carried out in the mode of electrodynamic liquefaction of graphite particles in a vacuum, and conditions are created under which the energy of the graphite particles exceeds the work required for their separation into layers during brittle fracture along the cleavage planes, which occurs as a result of particle impacts on the electrodes.

The method is carried out as follows. As a source for the production of graphene, graphite powder is used, the particles of which are placed in an electric field between two electrodes in a vacuum, with a potential difference sufficient to liquefy the particles (the movement of particles between the electrodes with their recharge on the electrodes), when qU / d> mg , where q is the particle charge, U is the potential difference of the electrodes, d is the interelectrode distance, m is the particle mass, g is the acceleration of gravity. For each passage through the interelectrode gap without the resistance of the medium in vacuum, the particle acquires energy qU. In this case, the particles experience point impacts on the electrodes, which leads to their brittle destruction along the cleavage planes perfect for graphite, that is, along the boundaries of graphene layers. A prerequisite for this process is the sufficiency of the energy accumulated by the particle before hitting the electrode qU, to perform the work of splitting the Esplit particle. To fulfill this condition, regulate the value of U - the potential difference of the electrodes. The sequential splitting of particles and their parts leads to the fact that the final product of the process is single sheets of graphene. The condition of carrying out the process in a vacuum provides the particle energy sufficient for splitting and the product purity. It should also be noted that graphene in a free state has no rigidity and curls up into a ball. However, in an electric field, having a charge, the graphene sheet unfolds and is suitable for further processing (displacement, sizing, and other operations) in the same vacuum space. In an inhomogeneous electric field, for example, with non-parallel electrodes, the particles also move towards a lower field strength. Therefore, to increase productivity, use is made of loading the source material in a narrow part of the interelectrode space and unloading the product in its wider part.

The method makes it possible to obtain graphene with high productivity and product purity.

The possibility of implementing the claimed invention is shown by the following example

Example

According to (CRC Handbook of chemistry and physics. 86 h edition. 2005-2006) graphite consists of two-dimensional graphene layers with a distance of 0.3354 nm between them with a binding energy in the graphene layer of 7.8 eV / atom and much weaker bonds between the layers 0.056 eV / atom, determined by van der Waals forces. The values of the bond energy between the layers, obtained experimentally, lie in the range from 0.043 to 0.061 eV / atom (Zacharia R., Ulbricht N., Hertel T. Interlayer cohesive energy of graphite from thermal desorption of polyaromatic hedrocarbones // Phys. Rev. 2004 V. B69, P. 155406). The two-dimensional graphene lattice consists of regular hexagons with a side dl = 0.1418 nm and an area (3) 3 / 2⋅dl2 = 5.35⋅10-20m2, two carbon atoms per cell. Then the specific binding energy of the layers per unit area of the particle cleavage surface is equal to

esplit = 2⋅ (0.056 eV / atom⋅ 1.602⋅10-19J / eV) / 5.35⋅10-20m2 = 0.335 J / m2

The energy required to split a particle with a split area Ssplit into two parts is Esplit = 2 Ssplitesplit, J.

The process of electrodynamic liquefaction consists in the oscillatory movement of conductive particles between the electrodes when they are recharged at the electrodes. When the particles are on the electrode, they acquire a charge q, which depends on the field strength U / d, and the charge is proportional to the surface area of the particle. In a vacuum, without experiencing the resistance of the medium, moving under the action of the force qU / d, where U is the potential difference of the electrodes, d is the interelectrode distance, the particle acquires energy qU (Myazdrikov O.A. Electrodynamic fluidization of disperse systems. Leningrad: Khimiya, 1984) ... The electrical conductivity of graphite in the layers is close to the metallic one, at the same time the electrical conductivity across the layers is hundreds of times less (Eletskiy A.V., Iskandarova I.M., Knizhnik A.A. et al. Graphene: methods of production and thermophysical properties. Advances in physical nauk, 2011, v. 181, No. 3, pp. 233-250). Therefore, a charged particle of graphite is a stack of dipoles (graphene layers) oriented along the field. On impact, the particle experiences a shear stress parallel to the graphite layers. With sufficient energy, this leads to a split of the particle. Since the charge of a particle q is proportional to the surface area of the particle, and the work on splitting a particle is proportional to its cross-sectional area, the ratio qU / Esplit does not depend on the size of the particle and is regulated by the value of U. (energy reserve) was more than one: qU / Esplit> 1. For spherical particles q = 2/3 π3r2ε0U / d, where r is the particle radius, ε0 = 8.85⋅10-12F / m is the dielectric constant (ibid.). When splitting along the maximum section, that is, in half, Ssplit = πr2 and the energy reserve is

qU / Esplit = (2 / 3π3r2ε0U2 / d) / (2πr2esplit) = (1 / 3π2) (ε0U2 / d) / esplit

It is important to emphasize that this ratio does not depend on the size of the particles, but only on their shape (the first factor). For ordinary conditions of electrodynamic liquefaction d = 10-2m and U = 3⋅104V, the energy reserve for spherical particles is 7.74. For asymmetric particles, for example, in the form of a hemisphere, and with a charge q = 3πr2ε0U / d (ibid.), The energy reserve is 3.6. For thin particles lying on the electrode, whose thickness is much smaller than other dimensions, the charge density is equal to the electrode charge density ε0U / d, and the charge is determined by the surface area. For thin disks q = πr2ε0U / d. Accordingly, the energy reserve is 1.19. Since for fine particles the size of the surface is close in the size of the cleavage area, this value will be the same for fine particles of a different shape. When the thickness of the particles decreases as a result of splitting less than a certain limit on impact, they begin to lose longitudinal stability, which leads to bending stresses. This further contributes to the separation of the particles. The condition for electrodynamic liquefaction qU / d >> mg is fulfilled for particles smaller than 1 mm at a graphite density of 2.3⋅103 kg / m3. Thus, all particles of any size and shape, less than 1 mm, for the accepted conditions d = 10-2m and U = 3⋅104V have enough energy for splitting. Therefore, the process goes to the end, that is, until the particles are split into single layers. It should be noted that the destruction of particles across the layers requires two orders of magnitude more energy. Taking into account the conservation of a part of the energy upon rebound from the electrodes, the maximum particle energy is qU (1-k2), where k is the momentum conservation coefficient during impact (ibid.). It is also advisable to use solid electrodes, for which a large impulse conservation coefficient is observed upon impact. This can increase the energy reserve by a factor of two or more. Thus, the proposed method makes it possible to increase the productivity of obtaining graphene from graphite.

Documents Cited in the Search Report1

Last time we recommend everyone to think about their actions. Otherwise, we will upset you to the indecency and very quickly bring you to a sense of reality.

Mr. Green Berets