The story of how graphene works in the human body .

New Year's gifts 🎁 you today my favorite gold and diamond slacker skiers ⛷ from North American Santa 🎅 Claus, Russian Santa Claus and Beijing Shan Dan Laozhen.

So it will be with all the greedy people who do not want to pay US our legal share!

Russian technology as a gift 🎁 for the New Year in the form of a graphene nanotube in the hand.

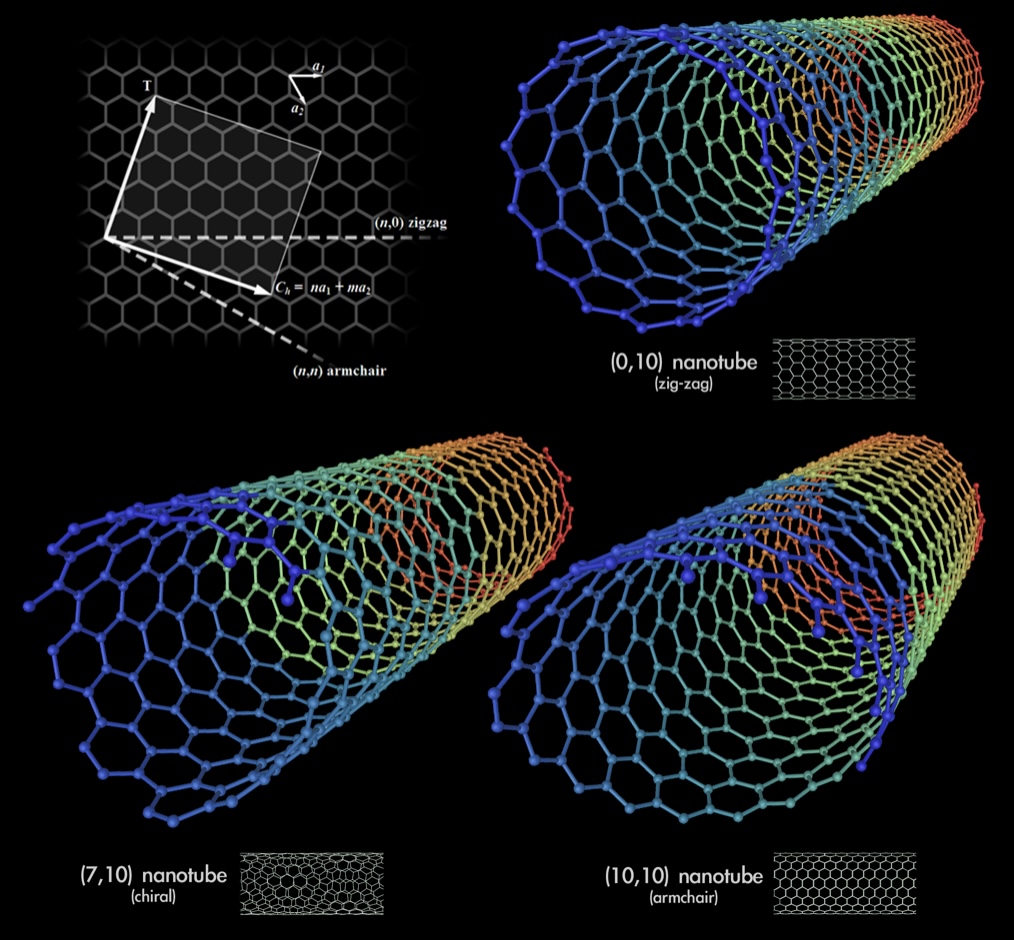

At the beginning of 2020, the Novosibirsk company OCSiAl launched a second unit synthesizing graphene nanotubes at the planned capacity. They are added to different materials. Previously, in the world, graphene nanotubes were obtained in limited quantities in laboratories and they cost about $ 150,000 per kilogram. They tried to mass-produce the German company Bayer, the French Arkema, the Chinese CNano and some other companies in the world, but only OCSiAl managed to produce single-walled tubes. OCSiAl is the only company that owns a scalable technology for the industrial synthesis of graphene nanotubes, their largest manufacturer in the world. Graphene nanotubes, or single-walled carbon nanotubes, are planes of graphene rolled into a cylinder. They have unique properties - high electrical and thermal conductivity, strength, length to diameter ratio. When material is introduced into the matrix, they create a three-dimensional network that gives the materials conductive and reinforcing properties. OCSiAl manufactures nanotubes under the TUBALL™ brand. In Novosibirsk, there are production facilities and research base of the company, as well as a center for prototyping materials and technologies based on graphene nanotubes - TUBALL CENTER. OCSiAl is a global company operating on all continents. Regional offices are open in Europe, the USA, Korea, China (Shenzhen, Shanghai), Hong Kong and Russia, representative offices in Mexico, Israel, Japan, India, Australia, Germany and Malaysia. In addition to its own offices and representative offices, OCSiAl has partners and distributors in 45 countries. OCSiAl employs more than 450 employees from 16 countries. The R&D company employs more than 100 scientists.

METHOD OF OBTAINING GRAPHENE

(19),RU(11), 2 632 688,(13),C1,(51),IPC

C01B 32/19(2017.01)/B82Y 40/00(2011.01)

B82B 3/00(2006.01)/(21) (22)

Request:

2016143665, 2016.11.07/(24)

Start date of the patent validity report: 2016.11.07,(22),Application date: 2016.11.07/ (45)/Published: 2017.10.09

(72), Authors:Zhebelev Sergey Ivanovich (RU)/ (73)/Patent holders:

Zhebelev Sergey Ivanovich (RU)/(56)

Documents cited in the search report:

FRANCESCO BONACCORSO et al.

Production and processing of graphene and 2d crystals, Materalstoday, 2012, v.15, N 12, p. 564-589. RU 2570069 C1, 10.12.2015. US 2013/0102084 A1, 25.04.2013. WO 2011/055039 A1, 12.05.2011. YELETSKY A.V. etc.

Graphene: Methods of Production and Thermophysical Properties, Uspekhi Physical sciences, 2011, t.

181, N. 3, p. 234-268. Abstract

The invention can be used in nanoelectronics. Graphite particles are placed in a vacuum between the electrodes, while the potential difference is established sufficient for electrodynamic liquefaction of particles and their production of energy exceeding the work required to split them along the planes of adhesion into layers of graphene during brittle destruction during impacts on the electrodes. Graphite with a density of 2.3 · 103 kg / m3 is used, the particles of which have a size of less than 1 mm. The invention allows to increase the productivity of obtaining high-purity graphene. 1 z.p. f-ly. Claims

1. A method for producing graphene by delamination of graphite in a vacuum, characterized by the fact that graphene is used to produce graphene, which is subjected to electrodynamic liquefaction between electrodes, the potential difference of which is established sufficient for their electrodynamic liquefaction and the receipt of energy by particles when they move between the electrodes, exceeding the work necessary to split the particles along the planes of adhesion when they hit the electrodes.

2. The method according to claim 1, characterized in that graphite particles with a size of less than 1 mm are used at its density of 2.3 ⋅ 103 kg / m3.

Description

The invention relates to the field of production of carbon nanomaterials, for example, graphene, and can be used to produce graphene for use in nanoelectronics. All currently known methods for obtaining graphene are long and expensive with a small yield of graphene (Yeletsky A.V., Iskandarova I.M., Knizhnik A.A. et al. Graphene: Methods of Production and Thermophysical Properties. Successes of Physical Sciences, 2011, vol. 181, No. 3, pp. 233-250).A method for the formation of graphene by delamination of graphite is known (see US patent 20130102084 A1, IPC C01B 31/04, H01L 51/00, H01L 51/42, publ.: 25.04.2013), combining a number of options involving the introduction into the space between the atomic layers of a graphite sample of metal salts (Li, Al, Fe, Cu) in organic solvents (propylene carbonate, N, N-dimethylformamide, dimethyl sulfoxide). Ions and organic solvent molecules expand the space between the atomic layers, which makes it possible to separate them when exposed to an external forcing force, which can have an electrochemical, thermal, microwave, solvothermal, acoustochemical or acoustic nature.The disadvantage of the method is low performance due to the long duration of the stages of its implementation.The closest to the claimed technical solution is a method for obtaining graphene particles or flakes by abrasion of solid graphite over a rough rough surface, for example, on a glass surface having a roughness of 0.01 to 10 pm. With friction, graphite is transferred to a rough surface with the leaving of traces, which are a graphene material. The surface is then sonicated to separate the graphene material from it (WO 2011055039, Cl. B82Y 30/00, 2011).

The disadvantage of the method is its low productivity, because the method requires a constant interruption of the process to separate the layers of graphene from the abrasion surface to restore roughness and continue the process of abrasion of solid graphite. The task to which the claimed invention is aimed is to increase the productivity of the process of obtaining carbon nanomaterials, in particular graphene. This problem is solved due to the fact that the claimed method of obtaining graphene by delamination of graphite differs in that graphite particles are subjected to electrodynamic liquefaction in a vacuum, in which the energy of graphite particles exceeds the work necessary to split them when the particles hit the electrodes. EFFECT, provided by the above set of features, is an increase in the productivity of the process of obtaining graphene.The essence of the proposed invention is as follows. In the proposed method of obtaining graphene, the process is carried out in the mode of electrodynamic liquefaction of graphite particles in a vacuum, and create conditions under which the energy of graphite particles exceeds the work required to separate them into layers during a fragile destruction along the adhesion planes that occurs as a result of particles hitting the electrodes. The method is carried out as follows. Graphite powder is used as a source for obtaining graphene, the particles of which are placed in an electric field between two electrodes in a vacuum, with a potential difference sufficient to liquefy the particles (moving particles between the electrodes with their recharge on the electrodes), when qU / d>mg, where q is the charge of the particle, U is the potential difference of the electrodes, d is the interelectrode distance, m is the mass of the particle, g is the acceleration of gravity. With each span of the interelectrode gap without the resistance of the medium in a vacuum, the particle acquires the energy qU. At the same time, the particles experience pinpoint impacts on the electrodes, which leads to their fragile destruction along the planes of adhesion perfect for graphite, that is, along the boundaries of graphene layers. A prerequisite for this process is the sufficiency of the energy stored by the particle before hitting the qU electrode to do the work of splitting the Esplit particle. To fulfill this condition, adjust the value of U - the potential difference of the electrodes. The sequential splitting of particles and their parts leads to the fact that the final product of the process is single sheets of graphene. The condition of the process in a vacuum ensures sufficient particle energy and purity of the product for splitting. It should also be noted that graphene in the free state has no stiffness and folds into a lump. However, in an electric field, having a charge, a sheet of graphene unfolds and is suitable for further processing (movement, sizing and other operations) in the same vacuum space. In an inhomogeneous electric field, such as non-parallel electrodes, particles also move towards a lower field strength. Therefore, to increase productivity, loading the source material in a narrow part of the inter-electrode space and unloading the product in its wider part are used. The method makes it possible to obtain graphene with high performance and purity of the product. The possibility of implementing the claimed invention is shown by the following example

Example

According to the CRC Handbook of chemistry and physics. 86 h edition. 2005-2006), graphite consists of two-dimensional layers of graphene with a distance between them of 0.3354 nm with a bond energy in the graphene layer of 7.8 eV / atom and significantly weaker bonds between layers of 0.056 eV / atom, determined by van der Waals forces. The values of the binding energy between the layers obtained experimentally lie in the range from 0.043 to 0.061 eV / atom (Zacharia R., Ulbricht N., Hertel T. Interlayer cohesive energy of graphite from thermal desorption of polyaromatic hedrocarbones // Phys.Rev. 2004. V. B69. P. 155406). The two-dimensional graphene lattice consists of regular hexagons with a side of dl = 0.1418 nm and an area of (3) 3 / 2 ⋅ dl2 = 5.35 ⋅ 10-20m2, two carbon atoms per cell. Then the specific binding energy of the layers per unit of the particle split surface area is equal to esplit=2⋅(0,056 eV/atom⋅1,602⋅10-19J/eV)/5,35⋅10-20m2=0,335 J/m2 .The energy required to split a particle with a split area of Ssplit of two parts is Equal to Esplit=2 Ssplitesplit, J. S. The process of electrodynamic liquefaction consists in the oscillatory movement of conductive particles between the electrodes when they are recharged on the electrodes. When on the electrode, the particles acquire a charge q, depending on the field strength of U/d, while the charge is proportional to the surface area of the particle. In a vacuum, without experiencing the resistance of the medium, moving under the action of the force qU / d, where U is the potential difference of the electrodes, d is the interelectrode distance, the particle acquires the energy qU (Myazdrikov O.A. Electrodynamic fluidization of dispersed systems. L.: Chemistry, 1984). The electrical conductivity of graphite in layers is close to metallic, at the same time the electrical conductivity across the layers is hundreds of times less (Yeletsky A.V., Iskandarova I.M., Knizhnik A.A. et al. Graphene: methods of production and thermophysical properties. Successes of Physical Sciences, 2011, vol. 181, No. 3, pp. 233-250). Therefore, a charged graphite particle is a stack of dipoles (layers of graphene) oriented across the field. Upon impact, the particle experiences a shear stress parallel to the layers of graphite. With sufficient energy, this leads to a split in the particle. Since the charge of particle q is proportional to the surface area of the particle, and the work on splitting the particle is proportional to the area of its cross-section, the ratio qU/ Esplit does not depend on the size of the particle and is regulated by the value U. To carry out the split of the particle, it is necessary that the ratio of the particle energy before hitting the electrode to the split energy (energy reserve) be greater than one: qU / Esplit> 1. For spherical particles q=2/3 π3r2ε0U/d, where r is the radius of the particle, ε0=8.85⋅10-12F/m is the dielectric constant (ibid.). When split at the maximum cross-section, that is, in half, Ssplit=πr2 and the energy reserve is equal to qU/Esplit=(2/3π3r2ε0U2/d)/(2πr2esplit)=(1/3π2)(ε0U2/d)/esplit It is important to emphasize that this ratio does not depend on the size of the particles, but depends only on their shape (the first multiplier). For normal conditions of electrodynamic liquefaction d=10-2m and U=3⋅104V, the energy reserve for spherical particles is 7.74. For single-ended particles, e.g. in the form of a hemisphere, and with a charge q=3πr2ε0U/d (ibid.), the energy reserve is 3.6. For thin particles lying on the electrode, in which the thickness is much smaller than other sizes, the charge density is equal to the charge density of the electrode ε0U/d, and the charge is determined by the surface area. For thin disks q=πr2ε0U/d. Accordingly, the energy reserve is 1.19. Since for thin particles the surface size is close in the size of the split area, this value will be the same for thin particles of a different shape. When the thickness of the particles decreases as a result of splitting less than a certain limit on impact, they begin to lose longitudinal stability, which leads to bending stresses. This further promotes particle delamination. The electrodynamic liquefaction condition qU/d>>mg is met for particles smaller than 1 mm at a graphite density of 2.3⋅103 kg/m3. Thus, all particles of any size and shape, smaller than 1 mm, have enough energy for the accepted conditions d = 10-2 m and U = 3 ⋅ 104 V to split. Therefore, the process takes place to the end, that is, before the particles split into single layers. It should be noted that it takes two orders of magnitude more energy to break down particles across the layers. When taking into account the conservation of part of the energy during rebound from the electrodes, the maximum energy of the particle is qU(1-k2), where k is the coefficient of conservation of momentum at impact (ibid.). It is also advisable to use solid electrodes, for which there is a large coefficient of conservation of momentum on impact. This can raise the energy reserve by two or more times. Thus, the proposed method allows to increase the productivity of obtaining graphene from graphite Documents cited in the search report1 Document Number Title RU2570069C1 GRAPHENE PRODUCTION METHOD Related documents20 Document Number Title

RU2644579C1 METHOD OF ASSEMBLING NANOMATERIALS FROM GRAPHENE

******

From 500 kilograms to 75 tons

Single-walled carbon nanotubes are used in the manufacture of lithium-ion batteries of mobile phones and other gadgets, flexible touch screens, tires and other automotive parts, self-leveling floors, sports equipment, batteries for electric vehicles and much more. You can even say: the size is small, but the presence is wide. Such nanotubes are five times lighter than copper, 100 times stronger than steel, withstand temperatures up to 1,000 ° C and, when added, even in the smallest proportions improve the characteristics of the material. For example, if you add 0.001% of single-walled nanotubes to concrete, it will immediately become stronger by 50%. In 2013, OCSiAl launched its first plant for the production of such graphene nanotubes called Graphetron 1.0. The brand was named TUBALL. A year later, the installation synthesized 500 kg of nanotubes, and by 2019 production reached 25 tons per year. Construction of the second Graphetron 50 unit began in 2016. In 2019, it worked in test mode and has only now reached a production capacity of 50 tons. OCSiAl can now produce 75 tonnes of single-walled graphene nanotubes annually. The volumes are enormous, especially when compared with foreign attempts to produce graphene nanotubes. But not everything is so simple – there are pitfalls that explain why the competitors did not succeed. Graphene nanotubes are an allotropic modification of carbon, which are rolled into a cylinder sheets of graphene one atom thick, while the tubes have special strength and flexibility. They are synthesized in installations in three ways:

using graphite electrodes;

by laser evaporation of a graphite target;

by chemical reaction of gases - carbon-containing and auxiliary.They are used in microelectronics, in the manufacture of plastics, automotive parts and in many other materials.

Carbon nanotubes

An attempt to create mass production of nanotubes from graphene was one of the first to be made by the German pharmaceutical company Bayer. The pilot plant, producing 60 tons per year, was launched in 2007, and in 2010 full production was opened, it was planned to produce 500 tons annually. The tubes were synthesized by catalysis from carbon-containing gas at high temperatures, but only multi-walled tubes were obtained - not graphene, but graphite tubes. Graphite was not as strong and flexible as graphene, and separating the tubes into layers was difficult and expensive, so Bayer products were not in great demand, and in 2013 the firm closed the project. The French company Arkema planned to produce 400 tons of nanotubes annually, the Chinese CNano - 500 tons. About 40 organizations in the world tried to open mass production, but they could not get single-wall tubes in each issue.Currently, they are also produced by the Japanese company Zeon, but it produces about a ton of tubes per year and sells at $ 10 per kilogram. According to Yuri Koropachinsky, the material looks like a sticky black web. It is 10 times heavier than air and 100 times lighter than water. It needs to be not only synthesized, but also transported in a special way. The installation is not just a reactor, but a robot plant that independently performs all operations. The finished crushed material is sent to a separate container, it is located at the end of the cycle. Land of Ideas, Phone of Happiness and $2 Million.In the mid-2000s, Yuri Koropachinsky decided to take a break from his numerous business projects, sold all his assets and went to live in Australia. The funds received were enough not to work and live comfortably, but in 2006 he decided to return to business, because he thought: a non-working father is a bad example for his son. Yuri Koropachinsky is the co-founder and president of OCSiAl. Before starting his business career, he participated in scientific research in the field of biophysics, working in the Siberian Branch of the USSR Academy of Sciences. He created his first venture capital company in the early 1990s. After the successful release of one of its investment projects in 2004 (a manufacturer of agricultural machinery with 20 thousand employees and a turnover of $ 230 million), he formed the company "SM.Group", which invested in promising high-tech start-ups, and since 2012 has focused on carbon nanomaterials, which led to the creation of the company OCSiAl. Koropachinsky gathered his business partners in previous projects - Yuri Zelvensky and Oleg Kirillov - and went to Novosibirsk. He wanted to invest in a high-tech business. Participating in the meeting of the Russian Academy of Sciences, Yuri announced that he was looking for original ideas.

Yuri Koropachinsky

However, the team of entrepreneurs went to the final idea for three years. The future creators of OCSiAl met with scientists from 23 research institutes in Novosibirsk, Tomsk, Krasnoyarsk and Irkutsk. Turning to each institute, the team asked the management to organize a meeting with scientists who had the most original inventions. At these meetings, businessmen asked: what do you know how to do better than anyone else or what no one else can do? If there was a specific answer to this question, the topic was discussed further. So the idea seekers considered 1,500 options, identified 364 projects in physics, chemistry and biology, in which they invested a little money to study their feasibility and potential market. "There were some pretty funny projects among them," recalls Yuri Koropachinsky. - For example, one scientist suggested a phone of joy, he even had confirmation from the Ministry of Communications of the Russian Federation. I asked how it worked, and he said, 'Like all cell phones, it's only when they start talking about it that everyone is happy.'" As a result, $ 2 million was spent, 12 projects were transformed into the company, but still Yuri could not call any of them truly unique.

Academician and nanotubes

In 2009, Mikhail Predtechensky, Director of the International Scientific Center for Thermophysics and Energy of the Institute of Thermophysics of the Siberian Branch of the Russian Academy of Sciences, came to a regular meeting with investors in Novosibirsk. By that time, he had been creating technologies for IT companies (HP, Samsung) and the gas industry (AirProducts) for 20 years. To the same question about what he knows how to do, Mikhail replied: "That's it," and offered to discuss the problem differently: "Tell me what you want to get, and I will make a breakthrough technology."

Mikhail Predtechensky and Anatoliy Chubais. Retreat:

Russian Tolya Chubais and the Club of Rome .In 1980, The Secretary of the CPSU Central Committee, Mikhail Gorbachev, who had made a party career with the help of Andropov, became a member of the Politburo of the CPSU Central Committee.

Chubais Sobchak Putin. Oleg Kalugin in this book also writes about his friendly relations with the orientalist Yevgeny Primakov, who in 1991 became the first deputy chairman of the KGB and the head of the First Main Directorate of the KGB of the USSR, in 1991-1996 he was the director of the Foreign Intelligence Service of the Russian Federation (that is, the immediate superior of G.M. Evstafiev at that time). In 1956-1970, Yevgeny Primakov officially worked as a journalist, first in the State Television and Radio, then in the newspaper "Pravda", and traveled a lot to the countries of the Middle East. Oleg Kalugin in 1960-1964 worked in the United States under the guise of a journalist - a correspondent of Moscow Radio. Another well-known intelligence officer, Major General Yuri Georgievich Kobaladze, was in the UK in 1977-1984 under the guise of a gosteleradio correspondent. The future director of the Foreign Intelligence Service of Russia (1996-2000), Army General Vyacheslav Ivanovich Trubnikov in 1971-1977 was engaged in intelligence activities in India and Bangladesh under the guise of a correspondent of the Novosti Press Agency. Yevgeny Primakov was the same KGB "journalist" as Oleg Kalugin and Yuri Kobaladze and Vyacheslav Trubnikov and Stanislav Levchenko, and their other Soviet colleagues. And so, over time, he headed first Soviet and then Russian intelligence. And Boris Yeltsin himself was the nominee of Yu.V. Andropov and he appointed Yevgeny Primakov Minister of Foreign Affairs (1996-1998) and then Chairman of the Government of Russia (1998-1999). Anatoly Chubais is our Russian hero of the coming year 2022. In addition to Anatoly Chubais, some other "young economists" from the Chubaisov circle, formed after oleg Kalugin's arrival in Leningrad, became outstanding criminal figures in the post-Soviet period: Alexey Kudrin, in 1996-1997 - Deputy Head of the Presidential Administration of the Russian Federation - Head of the Main Control Directorate of the President, in 2000-2011 - Deputy Prime Minister and Minister of Finance of the Russian Federation; Alfred Koch, in 1993-1996 - Deputy, First Deputy Chairman of the State Committee for Property Management, in 1996-1997 - Chairman of the State Property Committee, Deputy Chairman of the Government of the Russian Federation, in 2000-2001 - Director of the Gazprom-Media Holding; Sergey Ignatiev, in 1991-1992 - Deputy Minister of Economy and Finance of Russia, in 1992-1993 - Deputy Chairman of the Central Bank, in 1993-1996 - Deputy Minister of Economy, in 1996-1997 - Assistant to the President of Russia for Economic Affairs, in 1997-2002 - First Deputy Minister of Finance, since 2002 - Chairman of the Central Bank of the Russian Federation and at the same time Chairman of the Supervisory Board of Sberbank of Russia; Andrey Illarionov, in 1993-1994 - Head of the Analysis and Planning Group under the Chairman of the Government of the Russian Federation, in 2000-2005 - Advisor to the President of the Russian Federation; Dmitrieva Oksana Genrikhovna, in 1998 - Minister of Labor and Social Development of the Russian Federation, since 2007 - First Deputy Head of the faction "Fair Russia" in the State Duma of the Russian Federation; Alexey Mordashov, since 1996 — General Director of OAO Severstal. Under the leadership of General Kalugin in 1980-1987, some relatively young officers served in the KGB system for the city of Leningrad and the Leningrad region, who later became prominent figures of post-Soviet Russia: Alexander Bortnikov, since 2008 — Director of the FSB of Russia. Oleg Kalugin recalled of Bortnikov: "He was a very capable, purposeful employee. He always stood out from the general mass of state security officers for his efficiency. He was distinguished by the ability to evaluate people and events in a non-standard way... In a word, a man in his place"; Valery Golubev, since 2006 — Deputy Chairman of the Management Board of OAO Gazprom; Viktor Ivanov, in 2000-2004 - Deputy Head of the Presidential Administration of the Russian Federation, in 2004-2008 - Assistant to the President of the Russian Federation, since 2008 - Director of the Federal Drug Control Service; Nikolai Patrushev, in 1998 - Deputy Head of the Presidential Administration - Head of the Main Control Directorate of the President, in 1999-2008 - Director of the FSB of Russia, since 2008 - Secretary of the Security Council of the Russian Federation. Oleg Kalugin recalled About Patrushev: "he received the first promotion in his life from me", "we went hunting together. He loved to read books and was interested in music. A modern guy like that at the time... And in general, I liked him..."; Georgy Poltavchenko, plenipotentiary representative of the President of the Russian Federation in the Central Federal District in 2000-2011, since 2011 Governor of St. Petersburg; Vladimir Putin (in the Leningrad KGB - until 1984), in 1997-1998 - Deputy Head of the Presidential Administration - Head of the Main Presidential Control Directorate, in May-July 1998 - First Deputy Head of the Presidential Administration, in 1998-1999 - Director of the FSB of Russia, in 1999 and in 2008-2012 - Chairman of the Government of the Russian Federation, in 2000-2008 and since 2012 - President of the Russian Federation; Victor Cherkesov, director of the Federal Drug Control Service from 2003 to 2008.What's most impressive here? Oleg Kalugin's reviews impress us the most. A. Chubais on the decline of the human population and the challenges of the 21st century. 2011, IV International Forum "Rusnanotech-2011". An excerpt from the speech of Anatoly Chubais.

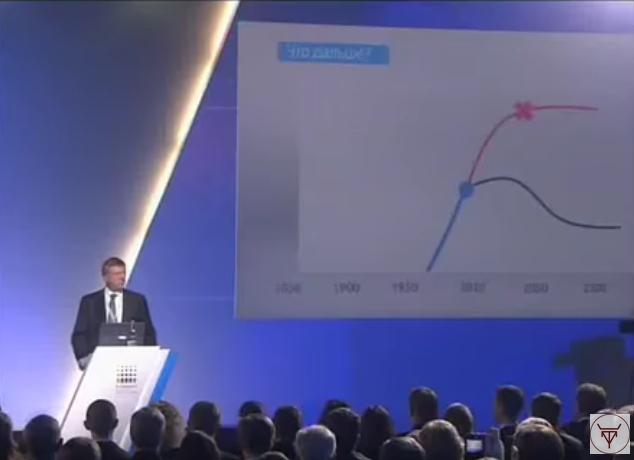

IV International Forum "Rusnanotech-2011". With the widest range of opinions of experts, scientists, analysts, today the absolute consensus forecast is that in the XXI century the extension of the trends of the XX century is unthinkable! This cannot be the case simply because physical limits exist in all kinds of resources on planet Earth. This means that the scenario of continued growth is excluded! Such a scenario in the same dynamics that has developed and we know, and with this dynamic we have spent our whole lives, this dynamic no longer exists and can not be! Not only that, it is well known that there is a very serious and very influential group of scientists who see the picture much more pessimistically. Or rather, almost catastrophic. These people say that we are facing not just stagnation, but we are facing a qualitatively new situation with a radical change in trend from upward movement to downward movement! And these are very serious people. These are not some marginals at all!

We know these serious people by the names Tolya! In fact, I'm talking about the well-known group of experts who in the 1970s created the Club of Rome, Aurelio Peccei and Dennis Meadows – a team of people who continue to work further. And they, with serious calculations and their arguments, say that the only scenario that we have to face is a scenario that is close to catastrophic. Well, imagine (shows on the graph), here the curve is so conditional, but in fact we are talking about the fact that the world's population from the very 7 billion that will be achieved this week, by the end of the century should drop to 2.5 billion, to two or even one and a half billion people.

Graph of changes in the population of mankind. This is a 3, 4-fold reduction in numbers! This is a trend that neither humanity nor the globe has ever experienced in its history. Such a scenario is absolutely catastrophic, consequences, the scale of which is still little realized. To be honest, it seems to me that regardless of whether you are a supporter of this approach or an opponent, but what is absolutely obvious is that we all need to do our best to prevent this from happening. There are children, there are grandchildren. 100 years is not thousands of years, it is quite a foreseeable period of time, and to lay a trend with a threefold reduction in population would be simply unthinkable, although this is exactly what serious scientists say. In our understanding, this trend is not acceptable, but if so, what exactly remains? Even at the level of common sense, not big analytics. It is quite obvious that there is only one trend left, this is the trend of balanced, sustainable development. The one that is talked about all over the world, and this is probably the only possible, the only meaningful option for the development of mankind in the 21st century, but we need to understand how this can be done. In our understanding, this can be done only with the solution, a breakthrough solution, of the main fundamental problems. Which relate to the creation of new materials, which relate to the creation of new energy, which relate to the creation of a fundamentally new medicine.

And we know about your materials and about syringes 💉 too! In other words, in fact, the existence of mankind is possible only with a radical change in the existing technological order. It is possible only if new materials and the new technosphere are radically less material-intensive, radically more effective, and if new medicine is able to solve the problem of maintaining human life with the duration that exists, and even prolonging human life. But in each case, we have to use the word "new", and in this sense, it seems to me that our country will respond to the scale of such a challenge.

From left to right, Sergei Ivanov, mentioned in the reference above, is the former Minister of Defense of Russia. You know, very often at this point, absolute pessimism, absolute disbelief begins. A very common perception is that none of this can be done, all this is chatter, no result will come of it. And the scale of this mood becomes simply frightening. Together with my colleagues at Rusnano, I represent the smaller part of the participants in the conversation who categorically disagree with this. Our position is exactly the opposite, and I will try to show why. In conclusion, it is necessary to formulate the essence of what was said. In my understanding, mankind now in the twenty-first century faces qualitatively new challenges and we, immersed in our current problems with the dynamics of economic development, GDP, debts, inflation, do not always see beyond this problem. The scale of these problems is unprecedented. Never before has humanity faced such problems. At the same time, I tried to show that our country can make a real contribution to solving these unprecedented challenges. As a result of long conversations, the scientist and entrepreneurs decided that it was necessary to work with the conversion of materials. In December 2009, during another conversation about projects, Mikhail Predtechensky said that he knew how to create nanotubes. He willingly said that they are very light, but durable, and improve the quality of many materials. There was only one minus - single-walled carbon nanotubes in small quantities were received only in the laboratory, so they were very expensive. Michael proposed to produce these tubes on an industrial scale. So, in February 2010, the company OCSiAl was opened, creating graphene nanotubes according to the method of Mikhail Predtechensky.Fateful Black Dots and Chubais. Predtechensky began to make tubes in a plasma generator, which he also invented himself. All the generators he used to work with had their electrodes burn out quickly. The production technology itself remains a trade secret of OCSiAl. It is difficult to reproach them for this - the competition in the market is high, and the possession of unique products brings great benefits. A plasma generator is a technical device in which plasma is formed with the help of an electric current, and it is used to process materials. 🎁 🎈 Michael came up with the idea to try to make liquid electrodes, because the liquid does not corrode. He made an arc between the baths, in which there was a melt, the metal melted, puddles turned out, and the arc closed. Now a generator with liquid electrodes could work any time with any material. It was this device that Mikhail Predtechensky used to create graphene nanotubes, the official name of which is SWCNT (from the English Single Wall Carbon Nanotubes - "Single Wall Carbon Nanotubes" - "Hi-Tech").

OCSiAl Laboratory.Officially, graphene is considered open in 2004. The discoverers are physicists Andrei Geim and Konstantin Novoselov, who received the Nobel Prize for this. But in fact, this substance was written about in the XX century. In 1952, the physical chemist Leonid Radushkevich obtained microscopic images of nanotubes after synthesis. And in 1977, scientists of the Institute of Catalysis of the Siberian Branch of the Academy of Sciences of the USSR during experiments with dehydration catalysts discovered carbon cylindrics under a microscope. In 1991, japanese physicist Sumio Iijima wrote about the discovery of such nanotubes. The full description of the technology by the Russians is kept secret, but the general principle is as follows: nanoparticles are formed on the substrate in the generator, flying in a gas heated to 1,000 ° C and above from hydrocarbons (methane and similar gases). On each nanoparticle grows a graphene nanotube. Synthesis takes place inside the installation. The production is patented. The main principle of mass production was to reduce the price of products to $ 1-2. Multi-walled carbon nanotubes are synthesized faster and easier, but their conductivity, flexibility and strength are much lower than that of single-walled ones, which means that they need to be added to the material in large quantities: if hundredths of a percent of single-walled nanotubes are enough to improve the properties of the material, then multi-walled ones require several tens of percent. In addition, it turned out that it is difficult to add multilayer tubes to materials. They are tangles of tightly intertwined tubes, which are difficult and expensive to untangle, and the powder from unwound tubes does not give the materials the necessary conductivity and strength, and it was bought little. Therefore, OCSiAl competitors producing multilayer tubes (Bayer, Arkema and others) were forced to curtail their production due to its unprofitability.

Anatoly Chubais. The synthesis of the first portion in the installation of Mikhail Predtechensky took a month. They turned out to be quite a few - several black speckles on the white background of the filter, but a special microscope showed that these are single-walled tubes. In the next two years, OCSiAl contributed $ 20 million to the development, but more investments were required, and in 2011 Yuri with a "spotty" filter went to the head of Rusnano Anatoly Chubais. Chubais surrendered to the confidence of the representative of OCSiAl. Rusnano invested $ 20 million - these were the first third-party investments. With these investments, the company built the first synthesizing plant Graphetron 1.0 in the homeland of the founders in Novosibirsk. A separate difficulty was to find buyers. "It takes a lot of effort and money," complains the company's founder. "But it is necessary to demonstrate to a potential buyer the effect of nanotubes specifically on his products. How do we do it? We take the material, add one ten-thousandth of a fraction of the nanotubes and we get a completely different material. "Nanotubes are evenly distributed in the material and create a reinforcing and electrically conductive network. For example, if you add single-walled nanotubes to the material from which lithium-ion batteries are made, it begins to conduct electric current better, which means that the batteries hold a charge longer. The first advertising move was to send free samples to manufacturers of various materials. One gram was sent to several thousand Russian and foreign companies, many were interested and responded. CNT was first bought by a Korean company to increase the strength of composites and conductive coatings. The management of OCSiAl realized that promotion would be effective only if they showed what result the addition of single-wall tubes to materials gives. Next door to Graphetron, the company opened a Prototyping Center, where it began to produce various materials with the inclusion of graphene nanotubes.

Tire using single-walled carbon tubes.For example, the company's scientists developed a technology for manufacturing self-leveling floors with CNT and transferred it free of charge to manufacturing companies, as a result of which 80% of such floors in Russia are created. Self-leveling floors made of materials in which single-walled carbon nanotubes are added have good electrical conductivity, in addition, nanotubes do not change the color of the materials, their viscosity and spreadability, so the consumption of materials in the manufacture of self-leveling floors does not increase. Similarly, technologies for creating fiberglass pipes and hardened asphalt have been developed. The addition of CNT to the resin from which fiberglass for fiberglass pipes is produced gives the material a volumetric and uniform conductivity, which reduces the risk of accidents in explosive industries (for example, in the coal industry), and the pipes become stronger by 15%. Asphalt concrete from bitumen containing carbon nanotubes becomes more resistant to the formation of ruts by 67%, and to the formation of cracks - by 67.5%. Initially, nanotubes were produced in powder form, but OCSiAl laboratories began to produce concentrates and suspensions for easier addition to materials. Now the second significant product of OCSiAl is TUBALL MATRIX concentrates and suspensions containing dispersed nanotubes. Adding nanotube powder to materials and evenly distributing it over any material is quite difficult, and uneven distribution will not give the effect of adding CNT. Therefore, OCSiAl specialists decided to create concentrates and suspensions with already distributed nanotubes. For this purpose, a special ultrasonic device TUBBOX was developed, which in turn uses mechanical and ultrasonic methods of dispersion. Mechanical dispersion produces homogeneous mixtures, and ultrasonic dispersion separates the nanotube bundles at the nanoscale into separate objects. 0.01% of TUBALL added to the material is evenly distributed over its matrix and creates a three-dimensional network with reinforcing and electrically conductive properties. OCSiAl primarily focuses on the market of lithium-ion batteries, in the silicon anodes of which nanotubes are added, the market of tires, asphalt coatings, composites and coatings. In 2019, the products were purchased by the Russian company Eco Group and added to the asphalt: with the help of adhesive additives, 0.025% of nanotubes were introduced into bitumen, and it was added to asphalt concrete. A section of the federal highway M4 "Don" is lined with new material, in the future it is planned to lay the road network with a coating of nanotubes.Among those who already use TUBALL are the Russian company Unicom-Service, which produces polyurethane shafts for conveyor belts (0.3% of TUBALL MATRIX concentrate adds for antistatic characteristics), the Chinese manufacturer of drill drills for oil rigs Orient Energy & Technology Ltd (1.7% of the concentrate is added to the rubber for stator elasticity in drills), the Russian manufacturer of glass containers Ekran (adds nanotubes to the spraying fluid). In Russia, there were no more than 2% of potential customers, so OCSiAl began to open offices in the USA, Europe and Asia. Now the company has 600 regular customers around the world, more than 2,000 companies test nanotubes, more than 90% of products are exported. In 2019, the investment group A&NN bought a 0.5% stake and valued the business at a billion dollars. Thanks to this, OCSiAl entered the list of so-called unicorns - new companies that have not yet overcome losses, but have already received a market valuation of $ 1 billion.

Anatoliy Chubais and Yuriy Koropachinsky. At the opening of Graphetron 50, Anatoly Chubais said: "OCSiAl is creating a new era of human materials. These are the fantastic properties of a single-walled carbon allotrope, which allows additives to almost any materials to increase the strength and electrical properties. All that has been done today is only the beginning of the path on which the global renewal of materials in the real sector on the globe stands. When i was approached by a young entrepreneur, cheeky and aggressive, I looked into those honest eyes and decided he could make it happen." Currently, the company is represented in 45 countries in Europe and Asia. At the same time, the head office was opened in Luxembourg. By 2023, OCSiAl intends to build a reactor there, producing 100 tons per year, as well as build reactors in all developed countries. "OCSiAl is actually a Luxembourg company," Yuri explains. To protect intellectual property, it is necessary to understand English law, to focus on consumers and investors around the world. The U.S. and Europe consume 25% of our production, so we place production closer to the main consumer. In addition, large companies want to receive supplies from different countries. So we need different locations." We have already made our conclusion with specialists: these technologies and materials are dual-use material technology. Combined with 5G towers and Richard Rothschild's 19 COVID 19 patents from 2015 to 2016 reserved in the Netherlands and a wide range of other national state secret programs, as well as a liquid called a vaccine by almost all administrations of the world, this is the NWO project. We consider the main authors and engines for the implementation of this communist Nazi project to be well-known and repeatedly voiced and shown figures from international institutions: the UN 🇺🇳, the International Bank of 🏦, WHO, Beijing, Washington, Moscow.

What's wrong?

Oh yes, even the Rockefeller Foundation, Clinton, Obama, Facebook, Google, Amazon Bezos, although this is all Washington along with the main orderly of the planet walking with a sheepdog on the beach in underpants on his face.

Oh you are my favorite 🤩 Why without me? Why didn't Adik's grandfather be called? Oh you little pranksters 😂

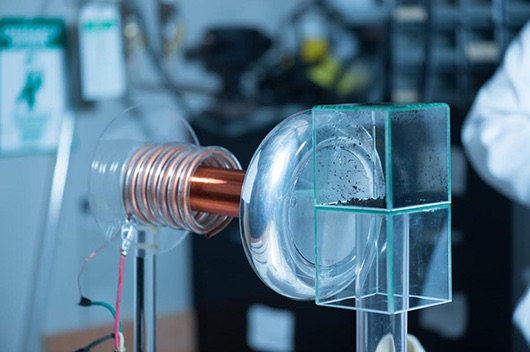

The guys in the lab are working with graphene oxide for practical use. This is how it happens in nanotubes for illumination, when graphene is excited electromagnetically, one of the applications they call "Teslaphoresis".Now we will tell and show how it is planned and carried out within the framework of the special operation CORONA 19 and works in the body of a digital slave containing a state gift in the form of graphene in the body.

https://t.me/Tribulelouis/20354

The fact that the technology of self-assembly of carbon nanowires using a Tesla coil was invented by scientists more than 6 years ago. And now, for some reason, the claim that graphene in vaccines can be used as a material to create a new electron-somatic nervous system inside a person is denied. Teslaphoresis is the remote control of matter, i.e. "self-assembly of materials at a great distance." Nikola Tesla invented his high-frequency high-voltage resonant transformer around 1891. Although he often experimented with ways to produce wireless electricity, he probably could not imagine that his slightly altered invention would be used for such a process as self-assembly. Teslaphoresis uses the same principle as electrophoresis, in which macromolecules are separated by a charge to move proteins. It moves matter remotely with the help of electric fields created by coils. Electric fields have been used before, but only for ultrashort distances, teslaphoresis also makes it possible to increase the strength of the fields for remote control of matter.

With the placement of a huge number of stuffed biological objects and a huge number of antennas on the planet, it is possible to create an artificial bioenvironment - ELECTRONIC ETHER. The ether (luminous ether, from ancient Greek αἰθήρ, Latin aether) is the subtle matter of all things — a hypothetical all-pervasive medium, the oscillations of which manifest themselves as electromagnetic waves (including visible light). The concept of the luminous ether was put forward in the XVII century by René Descartes and received a detailed justification in the XIX century within the framework of wave optics and Maxwell's electromagnetic theory. Some scientists call the ether the SPIRIT OF THE CREATOR. That is, the creation of an artificial environment based on carbon tubes of carbon and a network of antennas is the creation of environmental conditions for a new, i.e. a different spirit for another god. John 5:43 I have come in the name of my Father, and you do not accept me; and if another comes in his own name, you will accept him. All this wave genetics is 🧬 called by scientists. And to create an artificial environment - an electronic ether, it is necessary:

1 The condition is the creation of the environment within us — that is, the creation of an environment within us. filling with nanotubes a liquid biological object (a person is 70% water).

2 The condition is the creation of the environment around us - i.e. the spraying of special particles of "artificial ether" in the air. (Chemtrails)

3 Condition - the presence in the immediate vicinity of powerful magnetic coils. (They are already on 5G poles. They are placed in all national territories very quickly and almost simultaneously, there are many of them. Their inclusion on special settings and causes poisoning in the human body, which gives symptoms of the virus)

4 Condition — implantation of a controller that combines nanotubes into a network. (this will be the outline, because graphene from shmurdyak is only a material that combines the functions of fiber, nervous system and exoskeleton inside biological objects). So far, this controller is a smartphone. But the smartphone can be thrown away, so its advanced analogue in the syringe and it must be integrated inside the body so that it is impossible to get rid of it. All conditions are implemented at a time... The case is for what is described under paragraph 4. Therefore, all sorts of state QR codes that complicate free movement are forced to make an injection. For the same reason, there is a hunt for children. What's the conspiracy theory when everything is open and in plain sight? "This kind of control over the self-organization of nanomaterials can be not only a fascinating sight, but also a useful tool in regenerative medicine. Carbon conducts electrical charge very well, so the nanotubes grow in a controlled way, they can be used as a nervous system. Teslaphoresis in the long term can help create any nerve tissue or complex electrical circuits without directly interfering with the process. These nanotubes grow and act as nerves, and the controlled assembly of nanomaterials from the bottom up can be used as a template for applications in regenerative medicine," Bornhoft said. The nervous system is the relationship between the cells of the body and the brain controller, which allows the body to perform certain functions: movement, thoughts, actions. That is, another new nervous system will perform the same functions, namely: to impose thoughts, actions, behavior. That is, it will suppress the will - the feature that distinguishes a person from an animal and connects with God. Without a strong electromagnetic field, nanoparticles do not line up in a system of wires, which means that they will not build a different nervous system inside you. In addition, permanent irradiation can be organized only in large cities, where the equipment is in every quarter. Think about it, why would the revolutionary neo-Marx young man Klaus Schwab want to herd everyone into the cities? "Existing platforms can create a magnetic field and simultaneously conduct a translucency of the patient, and the doctor can be in another room or even in another city and control the magnetic field with a joystick," says Kim.

''We hope to use existing technology in the next phase to test our robotic filament in vivo.' All videos on this topic are recommended for viewing ⬇️

https://t.me/Tribulelouis/20355

📹 Teslaforez

https://t.me/Tribulelouis/20356

📹 TESLAPHORESIS IS HERE -- Mind Blow #104

https://t.me/TribulleNews/14196

📹 mm 30 - 300 ghs 5G carbon Nanotube self assembly Coherer Teslaphoresis & youtube went studio

https://t.me/Tribulelouis/20358

📹 Science Documentary:Future Scenarios, Nanotechnology, Carbon Nanotubes, Nanomagnetism

https://t.me/Tribulelouis/20359

📹 Robo-thread

Continuation / material on the topic of

https://telegra.ph/Russian---American---Chinese-case-of-the-crown--19-12-28