Which Air Compressor You Should Choose Between Rotary And Reciprocating Compressor

Vaishali AegisHow does the best compressor look? It’s compact, silent, runs all day with no electricity, and never breaks down. As no such possibility exists within the universe, we must select between unhealthy, good, better, and best.

As per air compressors Sharjah, you cannot distinguish best from worst by glancing at a compressor’s packaging in the same way as you cannot judge a book by its cowl. Instead, we need to look at the technology to ensure performance. Here is the important information that will help you get to a decision in choosing between rotary van compressors and reciprocating compressors.

Rotary Van Compressors Vs. Reciprocating Compressors

The technology

Apart from its fan and filters, the core technology of any compressor is its compression system. The actual technology any given machine uses to compress air will have the best impact on its performance.

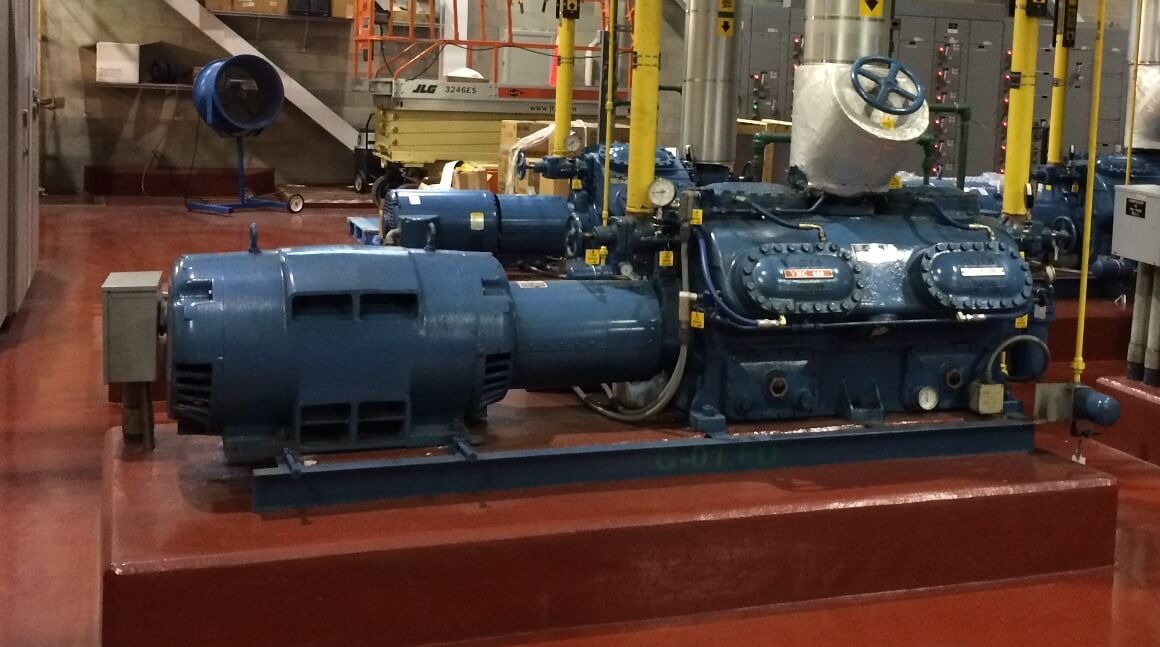

Reciprocating compressors employ pistons to compress air inside cylinders, then sent to the controlled receiving tank for further use. On the other hand, rotary compressors use rotors, and rotary vane compressors use one rotor with longitudinal slots and vanes that slide in and out of the rotor to make compression pockets.

The mechanism of rotary vane compressors is less complicated, additional sturdy, and economical than reciprocatory compressors (also known as “piston compressors”). Therefore, a better machine with more periods, higher energy potency, cost-effectiveness, higher air quality, and extended life.

Air compressor Sharjah says that the main advantage that piston-powered compressors supply is “upfront affordability.” however when you consider the operative period, maintenance, and energy prices, it seems to be more of cash entice than a real advantage. When you purchase a piston or reciprocating compressor, it seems you’re not buying an asset. Rather you’re buying a multi-year subscription to a machine whose monthly payment skyrocket over time as its quality plunges. Your razor handle may be low-cost; however, what proportion do the blades cost?

Whether you believe it or not, Rotary vane compressors get more energy economical over time; thus, your prices decrease as your machine gets higher. And that they don’t kick the bucket in 5 or 10 years the manner reciprocatory machines do. Thus, when you list a rotary vane machine on your books as an asset, it’s not simply a nominal designation.

So now, let’s take a glance at the compressor core four: time period, energy potency, expectancy, and air quality, and see how rotary vane technology earns its advantage.

Energy potency

Air compressor Sharjah conclude that 83% of total air compressor prices associate with energy usage, whereas the machine itself solely amounts to 11% of its lifetime prices. You won’t see these expenses on a tag; however, you’ll see them monthly on your electricity bill.

That is why energy potency is probably the most important term to contemplate when buying an air compressor. You would like a system that delivers more air for less energy, and that’s what rotary vane machines do. The advanced style of rotary vane compressors creates a near-perfect airtight confine the rotor mechanical device unit, which reinforces meter potency and reduces the quantity of energy needed to deliver the air.

Rotary vane compressors can gain up to 90% of mechanical efficiencies, which is impossible for reciprocatory machines. Reciprocatory compressors run at higher speeds and create more friction, heat, and wasted energy. In contrast, rotary vane compressors run slow, with stripped friction, reduced operative temperatures, and larger potency.

Uptime [ Duty Cycle]

Your compressor is solely helpful when it’s compressing air. Sadly, no compressor will run non-stop as each machine needs some downtime. However, some need quiet more than others. As per Air Compressor Sharjah, piston compressors need downtimes of between 30% and 50% to forestall heating, element wear, oil carbonization, and breakdown.

So, when you’re selecting a piston mechanical device, you’ll get to choose around double the quantity of cfm your application needs. On the other hand, Rotary vane compressors will run at 100% of their rated capacity for a full twenty-four-hour workday while not experiencing any premature wear or injury.

Since the uptime on rotary vane compressors is much higher, you may use a smaller machine. And smaller machines need less energy to run, which means you’ll save huge on your energy bills.

Air Quality

The reliable yield of high-quality air is a requirement when it involves air compression systems. Rotary vane compressors integrate high-efficiency filtration systems that ensure that very little as 1-3 ppm of oil carryover enters the air system, preventing instrumentality injury and product contamination. Reciprocating compressors, on the opposite hand, usually witness twenty-five ppm or additional oil carryover.

Rotary vane compressors gained value for their reliable delivery of high-quality air that keeps everything downstream running higher and longer.

Life Expectacy

Rotary vane compressors are born to last. And rotary compressors last much longer than reciprocatory compressors. It’s not uncommon for rotary vane machines to exceed their already impressive designed life of 100,000 hours. And therefore, the reasons are clear: low operative speeds, stripped friction, easy engineering, and proprietary pre compressor.

While reciprocating compressors may have a favorable position when it involves “upfront affordability,” their sturdiness leaves something tangible to desire. High operative speeds, tremendous friction, complicated engineering, and parts designed for planned devolution mean that piston compressors are nearer to the top of their life on day one than a rotary vane compressor with a decade of toil behind it.

Long live Rotary Van Compressors

With taken-for-granted blessings, in all areas, rotary vane compressors are plain higher than their reciprocatory counterparts. With immense savings in the time operative expenses, the initial investment prices its weight in ROI. A rotary vane compressor bought from Air Compressor Sharjah can be the last compressor you’ll ever need to buy.

Conclusion

Here was a detailed description of how rotary van compressors is better than reciprocating compressors by Air Compressor Sharjah. I hope the article can sort the confusion of people stuck between rotary and reciprocating compression and direct the individual to make the best choice. Rest the decision is all yours.