The Use of Laser Cutting in Sheet Metal Prototyping

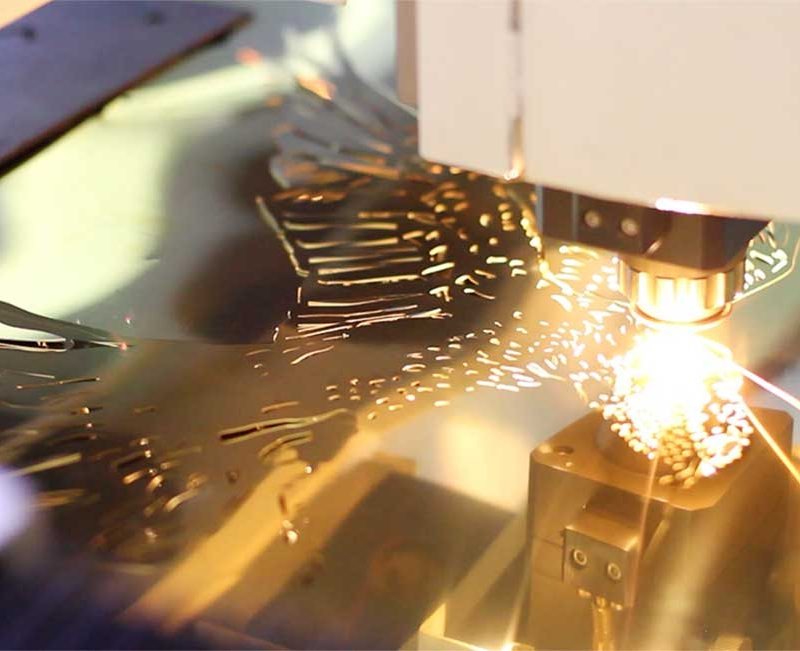

Do you have a sheet prototype that you simply got to find a production system for? Is laser cutting the method you would like to supply your prototype? the utilization of laser cutting in sheet prototyping is often fast, cost-efficient, and make well-made, quality prototypes for your projects. Following may be a bit of laser cutting history, evidence of the kinds of laser cutting London, and therefore the advantages of using laser cutting in sheet prototyping.

Though there is a variety of the way that sheets are often shaped and cut, few are as precise, reliable, and cost-effective as laser cutting. The technology involved in laser cutting is so effective that a continuation and improvement of its future capabilities is inevitable.

Laser Cutting History

Laser cutting was first used quite 50 years ago, around 1965, to drill holes in diamond dies. the utilization of laser cutting in other areas began around the 70s. Laser cutting was especially effective within the aerospace industry due to its ability to supply clean-cut edges. Unfortunately, within the early years of laser cutting use, manufacturers weren’t ready to utilize laser cutting because it is today, thanks to the shortage of technology and guidance currently available4.

Categories of Laser cutting Tools

Laser-cut may be a versatile tool whose use is often applied across a broad spectrum of materials like stone, glass, wood, plastic, and sheet.

A CO2 laser may be a popular sort of tool that's prized because it's easy to regulate and highly accurate. A beam made from concentrated CO2 gas is activated by electricity to fuel the cutting.

A fiber laser uses glass fibers to extend the potential of a seed laser. The result's a laser that's both more powerful and more precise in comparison to a CO2 laser. A fiber laser is usually used for metals due to its focused and intense beam.

A crystal laser is analogous to a fiber laser except it uses both pump diodes and crystals to get the intensity of its beam. A crystal laser features a comparable performance and application potential to a fiber laser cutting East London.

There are numerous reasons why using laser cutting is that the preferred method when developing a sheet prototype.

More Intricate

Because a laser has a mean size of only a couple of micrometers, it allows for precision to make and cut sheet prototypes that might be impossible if other methods were utilized. This leads to an almost limitless array of possibilities.

Finished edge

Using a physical technique, like a blade, to chop sheets leads to imperfections, like roughness and burrs, along the sting. for several designs, these would wish to be buffed out or otherwise removed which may increase the time it takes for the end-user to receive their product. employing a laser eliminates this issue.

Scalability

The tools enable companies to chop as many or as few sheet prototypes as their customers need. These lasers often do not have to be adjusted or retooled to accommodate the planning of a specific piece. When adjustments are inevitable, they're easier to accomplish when employing a laser cutter.

Laser Cutting and therefore the Future

As of immediately, CO2 lasers are still the industry standard though fiber lasers are being adopted rapidly. Although fairly new, the fiber laser technology is projected to become standard over the subsequent 10 to fifteen years. Many companies will still use their CO2 lasers alongside their fiber lasers, giving them more options for designs they will offer their customers. It could even be paired with 3D printing to make precise and reliable products for patrons.

Original Source: Laser Cutting Company London