Laser Cutting - A Contract Manufacturing Overview

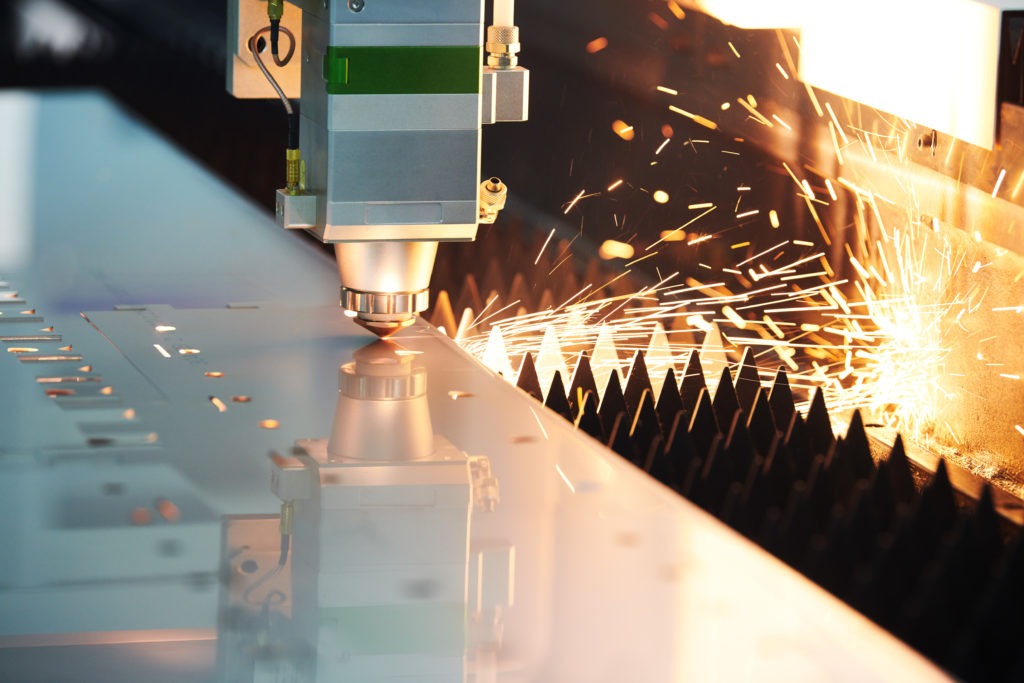

As the name suggests, laser cutting East London may be a cutting technology that creates the use of laser beams of varying intensities to chop materials. There are several reasons why laser cutting is preferred to other methods like plasma cutting.

Lasers are capable of offering unprecedented levels of machining, especially in micromachining applications. Here are some basic and well-known advantages of using lasers as a cutting medium:

The heat-affected zone is extremely small or negligible. This results in minimal distortion of parts.

Since part distortion is minimal and therefore the overall finish quality is far better than other cutting methods, the necessity for secondary finishing operations is drastically reduced.

It is one of the foremost preferred cutting methods for intricate part cutting. This cutting technique is capable of providing narrow kerf widths.

Highly advanced laser systems are often custom-built for specialized tasks. Customization also ensures that these machines have very high repeatability.

Since laser cutting London processes are CNC controlled, close nesting of parts ensures minimal material wastage. Less material wastage translates into more dollar savings.

Laser-enabled cutting processes are much faster and more precise than most other cutting processes.

Thus, when it involves achieving exacting tolerances and dimensions on small, thin, delicate, and high-precision parts, cutting with lasers may be a recommended option.

What do you have to expect from a contract manufacturer offering laser cutting services?

Engaging the services of a contract manufacturer for laser-enabled cutting services offers a myriad of benefits. First, it renders flexibility to your operations and saves you of intensive capital investment and time-consuming installation and training processes. On the opposite hand, a contract manufacturer would have specialized expertise during a narrow field and therefore the required capital investments in situ.

Laser-enabled cutting is often enabled for applications like precision cutting of surgical tools, medical devices, stents, also as dental, orthopedic, and cardiovascular implants.

An experienced contract manufacturing services provider can use their advanced lasers to chop a spread of metals including but not limited to: Nitinol, superalloys, nickel, tungsten, titanium, steel, copper, brass, aluminum, and more. additionally to those commonly used metals, other materials like plastics, wood, ceramics, fused quartz, rubber, and a number of other composites are often cut using lasers.

Precision tube cutting is another sought-after application of laser-enabled cutting. Precision tube cutting is usually achieved by introducing a 4th axis that's used for rotating the tube during the cutting process. Using this unique method, tubes within the range of 0.0125" to a 6" diameter are often cut. These tubes are widely utilized in medical devices also as implants. With the utilization of multi-purpose laser cutting systems, it's possible to achieve the precise dimensions on small also as large parts.

Original Source: Laser Cutting Company London