How What Are The Differences Between Etching & Engraving? can Save You Time, Stress, and Money.

Little Known Questions About Laser Etching & Engraving Applications and Machines - MECCO.

Contact Us Today for more information With our laser etching, inscribing and marking systems, you can attain the clear, high-quality marks your company needs. To find out more about our laser makers, and what they will accomplish for you, make sure to call us and we'll be delighted to answer any questions you might have.

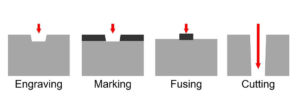

Laser Marking vs. Chemical/Acid Etching Laser Marking and Inscription is a commonly expanding market as users have actually seen the benefits of utilizing lasers over standard methods like Chemical/Acid Etching for direct part marking to basic gift personalization. What are those benefits? No Consumables, Chemical/Acid Etching is the use of an extreme Chemical/Acid to accomplish the marking.

In addition, stencils must be created after 20-30 markings if the info does not change. If the details modifications, like that of an identification number, the stencil needs to be altered each and every time. Chemical/Acid Etching is harsh to the environment, it requires more in advance to setup as you require appropriate filtering equipment, and the etching needs to have a new stencil after 20-30 times being used.

Rates, The Chemical/Acid Etchers are really less costly than most direct part laser marking systems, however, to in fact carry out one into your facility would end up costing more in the beginning and throughout the life of the product. Why? Check it Out for a wastewater filtering system or a licensed 3rd party, the services required to create the marking, and the stencils that are used to develop the markings.

Some Known Factual Statements About Laser Etching vs Laser Engraving (WASD) - GeekhackRMI Laser has produced the lowest-priced direct part marking laser on the marketplace today. This laser only needs an 110v outlet, an area to put the laser, and your parts for marking. Nothing for disposal, nothing to continuously change, and no liabilities. Effect Marking vs. Non-Impact Marking, Chemical/Acid Etching needs heavy contact with the part before and after marking.

Laser Engraving vs Laser Etching: Which is Better?

Laser Engraving vs Laser Etching: Which is Better? Laser Etching and Laser Engraving Service - JW Machine

Laser Etching and Laser Engraving Service - JW MachineSecond, the Chemical/Acid option is used to the part. Third, a repairing solution must be applied. Lastly, after 3 actions, the part can be cleaned off to lastly expose the etching. RMI Laser Marking Systems supply non-contact markings from starting to end. The part merely requires to be positioned under the laser at the appropriate focal height and the laser will engrave the part without the need for consumables, washing or surface area treatment.