Artemis

https://blogs.nasa.gov/artemis/

Around 4:15 a.m. ET the Space Launch System rocket and Orion Spacecraft for the Artemis I mission arrived atop Launch Complex 39B after a nearly 11-hour journey from the Vehicle Assembly Building at NASA’s Kennedy Space Center in Florida.

In the coming days, engineers and technicians will prepare the Artemis I rocket for its final major test – the wet dress rehearsal. The approximately two-day test will demonstrate the team’s ability to load cryogenic, or super-cold, propellants into the rocket, conduct a launch countdown, and practice safely removing propellants at the launch pad. After wet dress rehearsal, engineers will roll the rocket and spacecraft back to the Vehicle Assembly Building for final checkouts before launch.

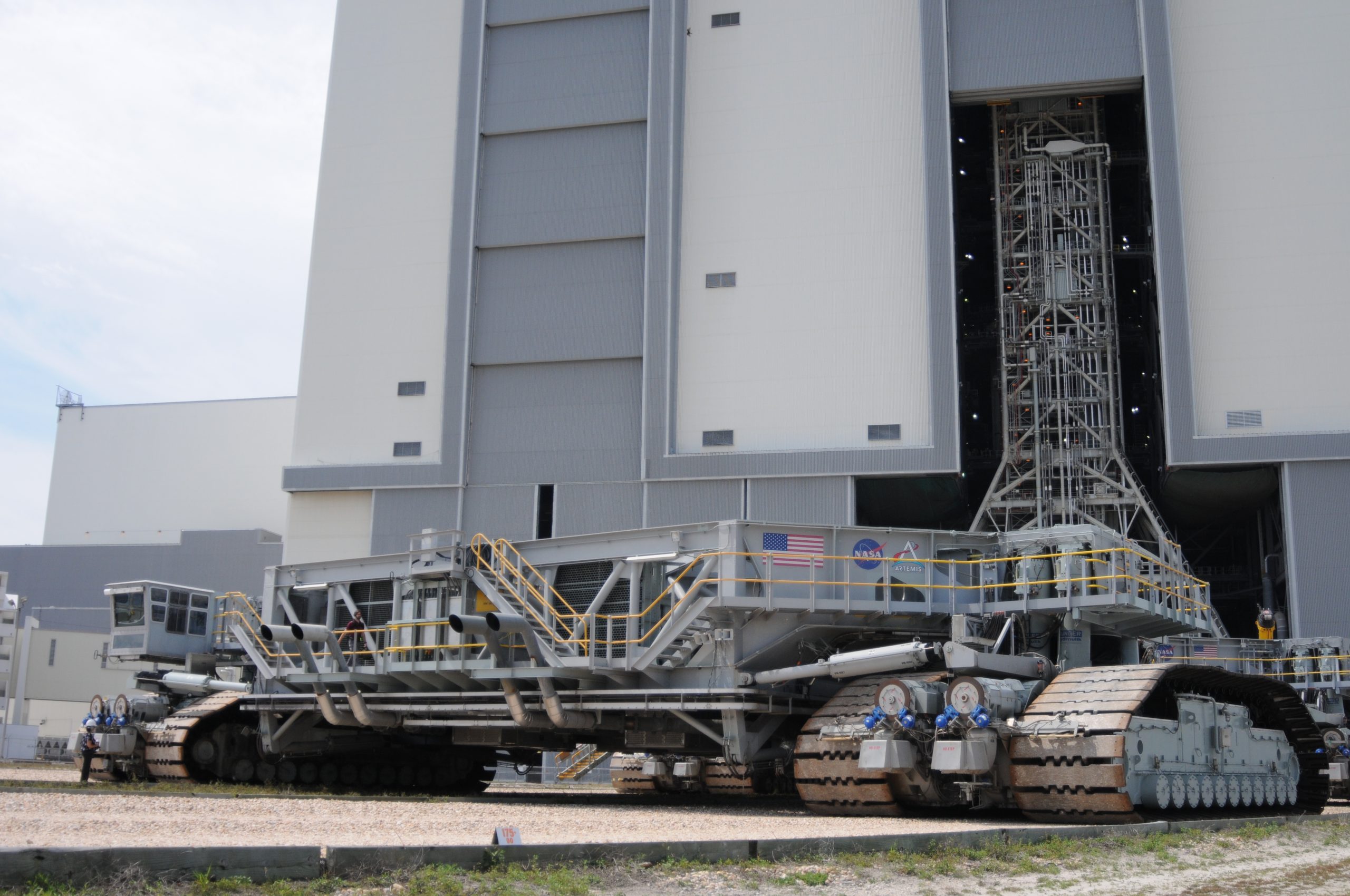

NASA’s mega-Moon rocket continues its four-mile journey to the launch pad after leaving the Vehicle Assembly Building after a planned stop to adjust the Crew Access Arm. Traveling at a top speed of .82 mph, the crawler-transporter with the Space Launch System rocket and Orion spacecraft atop the mobile launcher is on its way to Launch Complex 39B.

Once at the launch pad, the team will begin final preparations ahead of the wet dress rehearsal test.

The rocket and spacecraft for NASA’s Artemis I mission has fully left Kennedy Space Center’s Vehicle Assembly Building (VAB) for the first time on the way to Launch Complex 39B for a wet dress rehearsal test.

The team is in a planned pause outside the building to retract the Crew Access Arm (CAA). The arm interfaces with the Orion spacecraft stacked atop the Space Launch System (SLS) rocket to provide access to the Orion crew module during operations in the VAB and at the launch pad. On crewed Artemis missions beginning with Artemis II, the access arm also will provide entry and exit for astronauts and payloads that will fly aboard. Several days before the rollout began, the arm was moved closer to the rocket to fit through the VAB door. Engineers are extending it to lock it in its travel position.

Once the CAA retraction is complete, the team will continue the four-mile trek to Launch Complex 39B.

The Space Launch System rocket and Orion spacecraft for the Artemis I mission are rolling to Launch Complex 39B at the Kennedy Space Center in Florida for the very first time. At about 5:45 p.m. ET, with the integrated SLS and Orion system atop it, the crawler-transporter began the approximately 4-mile, journey from the Vehicle Assembly Building (VAB) to the launch pad. Once outside the VAB high-bay doors, the Moon rocket will make a planned pause allowing the team to reposition the Crew Access Arm before continuing to the launch pad. The crawler-transporter will move slowly during the trek to the pad with a top cruising speed of .82 mph. The journey is expected to take between six and 12 hours.

After they arrive at the pad, engineers will prepare the integrated rocket and Orion spacecraft for a critical wet dress rehearsal test that includes loading all the propellants

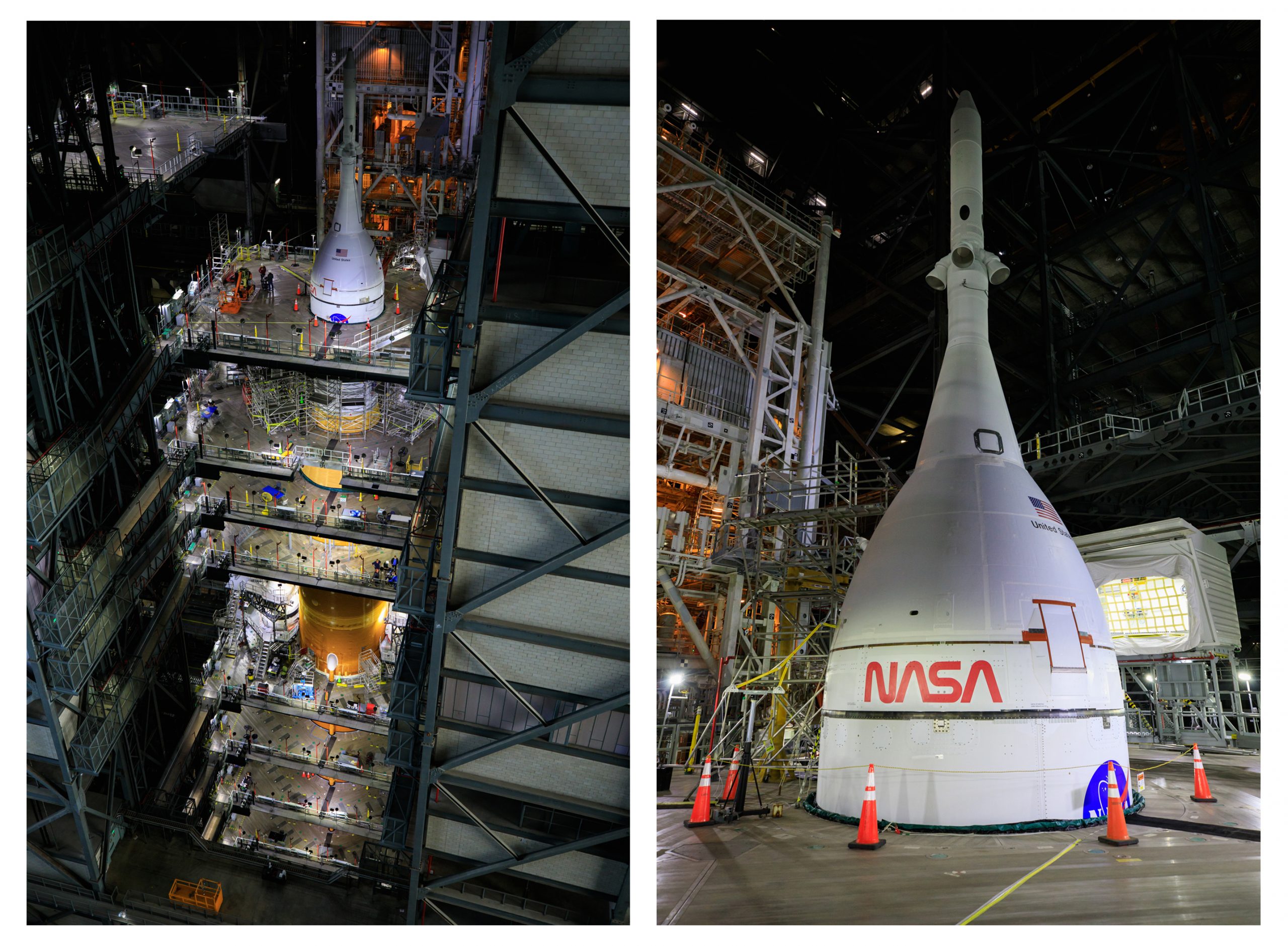

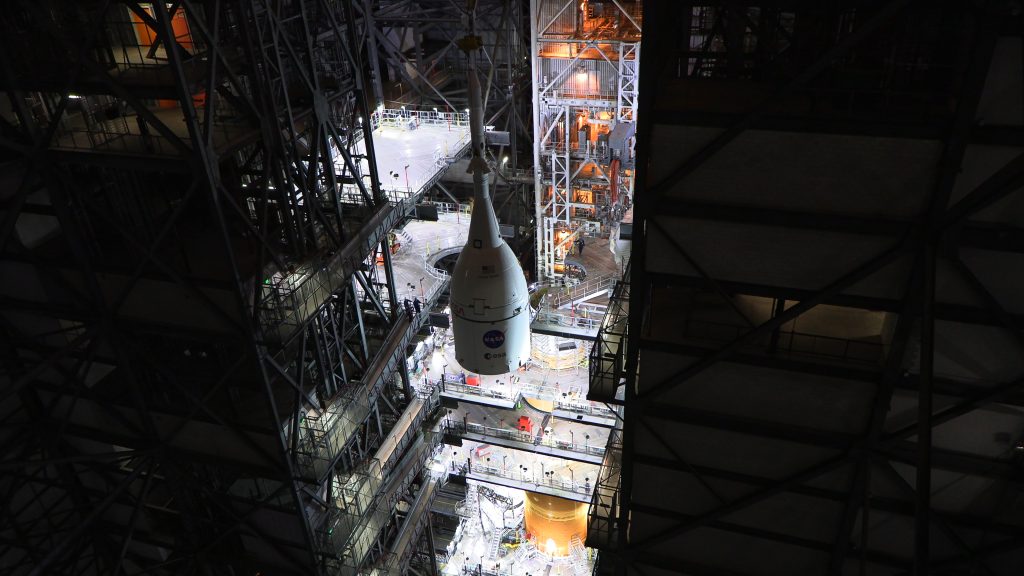

NASA’s new Moon rocket stands poised inside Kennedy Space Center’s iconic Vehicle Assembly Building ahead of its first journey to the launch pad. Comprised of NASA’s Space Launch System (SLS) rocket and Orion spacecraft, and sitting on its mobile launcher, the Artemis I Moon-bound rocket is ready to roll March 17 to Launch Complex 39B for its wet dress rehearsal test targeted to begin on April 1.

The dress rehearsal will demonstrate the team’s ability to load more than 700,000 gallons of cryogenic, or super-cold, propellants into the rocket at the launch pad, practice every phase of the launch countdown, and drain propellants to demonstrate safely standing down on a launch attempt. The test will be the culmination of months of assembly and testing for SLS and Orion, as well as preparations by launch control and engineering teams, and set the stage for the first Artemis launch.

The uncrewed Artemis I mission is the first flight of the SLS rocket and Orion spacecraft together. Future missions will send people to work in lunar orbit and on the Moon’s surface. With the Artemis missions, NASA will land the first woman and the first person of color on the Moon and establish long-term exploration in preparation for missions to Mars. SLS and Orion, along with the commercial human landing system and the Gateway that will orbit the Moon, are NASA’s backbone for deep space exploration.

Live coverage for rollout begins at 5 p.m. EDT and will include live remarks from NASA Administrator Bill Nelson and other guests. Coverage will air on NASA Television, the NASA app, and the agency’s website.

Live, static camera views of the debut and arrival at the pad will be available starting at 4 p.m. EDT on the Kennedy Newsroom YouTube channel.

Earlier today, engineers and technicians at NASA’s Kennedy Space Center in Florida drove Crawler Transporter-2, which will carry NASA’s Moon rocket to the launch pad, to the doors of the Vehicle Assembly Building (VAB). Soon, the 6.6-million-pound crawler will go inside the VAB and slide under the Space Launch System rocket and Orion spacecraft placed on the Mobile Launcher. Technicians will finish up preparations to transport the rocket traveling at a top speed of 1 mph to Launch Complex 39B for a wet dress rehearsal test ahead of the Artemis I launch.

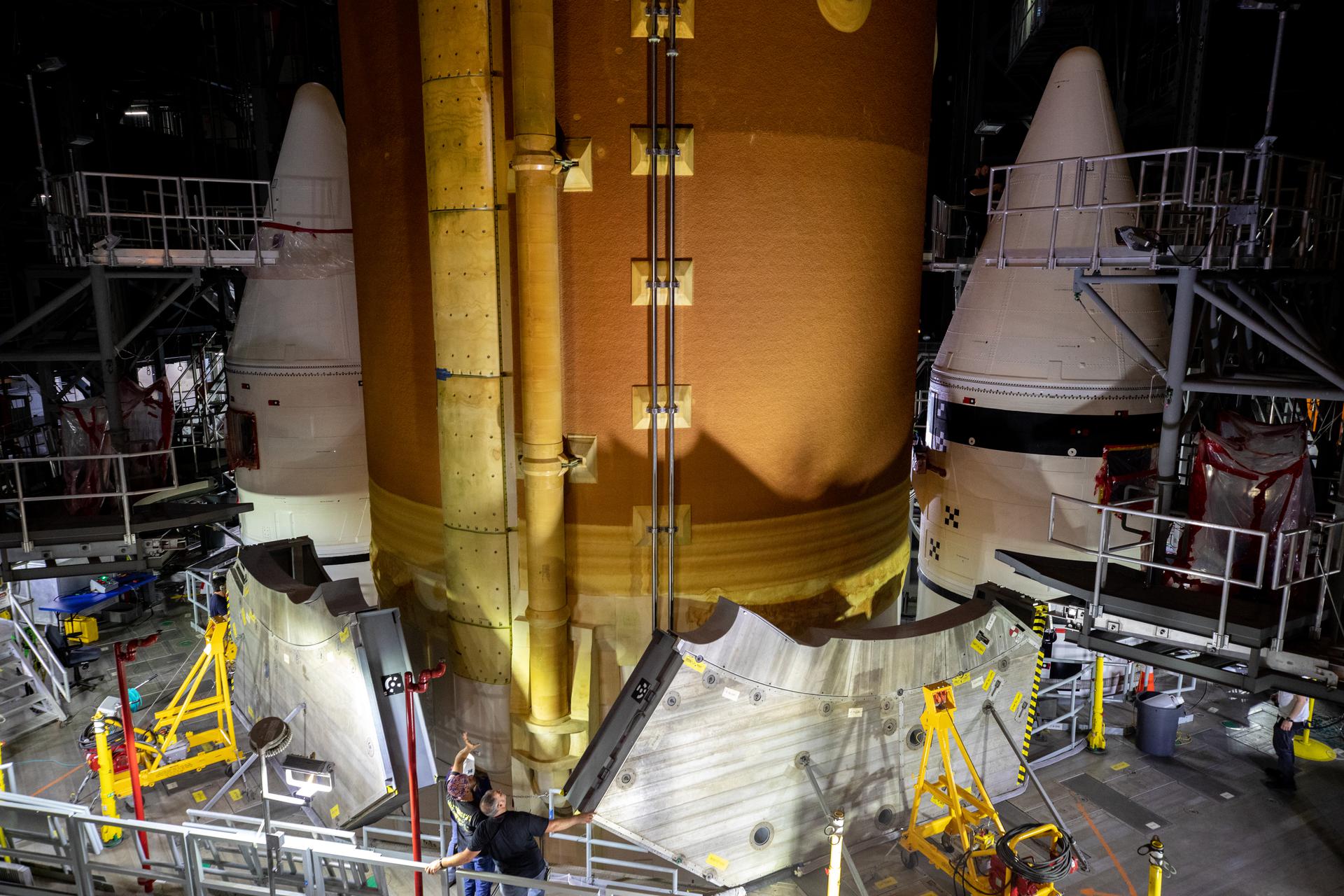

This week, the Kennedy team also completed painting the NASA worm logo on the Space Launch System solid rocket boosters. While painters added parts of the iconic logo before the segments were stacked, they had to wait until the boosters were fully assembled to finish the job.

In addition, the team has continued to retract the 20 platforms that surround the Space Launch System rocket and Orion spacecraft ahead of rollout on March 17 for the wet dress rehearsal test. The wet dress rehearsal will be the final major test for the Artemis I mission and will ensure the rocket, spacecraft, ground equipment and launch team are “go” for launch.

The Artemis I Moon rocket is getting closer to rolling out of the Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center in Florida for the first time.

The first two of 20 platforms surrounding the Space Launch System (SLS) and Orion spacecraft that allow work on the integrated system inside the building were retracted for roll out to Launch Complex 39B. Teams retracted the platforms, which move like hydraulic kitchen drawers, near the launch abort system on the Orion spacecraft in anticipation of the roll.

Teams are continuing to install instrumentation on the SLS’s twin solid rocket boosters inside the VAB. Thousands of sensors and special instruments will monitor the rocket and spacecraft as they roll out for the first time on March 17 and make the four-mile journey to Launch Complex 39B, arriving on March 18. Engineers will capture as much data as possible on the performance of all the systems that are part of the rocket, spacecraft, ground systems used for rollout, and on the pad for propellant loading and other activities. Once all the rocket and spacecraft systems are inspected, the 322-foot-tall rocket will roll to the launch pad for the wet dress rehearsal test, which is scheduled to occur approximately two weeks after it arrives to 39B.

The last steps remaining before rollout include inspecting each piece of the rocket and spacecraft, including physically entering different components of SLS and, step-by-step, making sure SLS and Orion are ready for the trip to the launch pad. As inspections continue, the Kennedy ground systems team is working to remove equipment and scaffolding away from the rocket and will continue retracting the platforms until the entire rocket is revealed.

Since replacing an engine controller on RS-25 engine number four that is on the Space Launch System (SLS) rocket core stage, NASA, and lead engines contractor Aerojet Rocketdyne, have performed a series of tests to ensure the engines and controllers are ready to support the Artemis I mission. All four engine controllers performed as expected during power up, as part of the Artemis I Core Stage engineering tests.

Aerojet Rocketdyne and its manufacturer of the engine flight controller, conducted numerous tests on the faulty engine four controller and determined the cause to be a faulty memory chip. The device is used only during the controller start-up sequence and has no impact on controller operations beyond that point. There is no indication of faulty memory chips on the other three engines, and therefore no related constraints to the wet dress rehearsal or launch.

Kennedy teams are completing remaining SLS pre-flight diagnostic tests and hardware closeouts, including testing the flight termination system on the SLS and installing instrumentation on the twin solid rocket boosters, in advance of rolling the rocket and spacecraft to Launch Pad 39B for the first time next month for a final test before launch. This final test, known as the wet dress rehearsal, will run the launch team through operations to load propellant into the rocket’s tanks and conduct a full launch countdown.

During the test at the launch pad, engineers will be on duty in the Launch Control Center and in other stations where they will work during the Artemis I launch. They will capture as much data as possible on the performance of all the systems that are part of SLS and the Orion spacecraft as well as the Kennedy ground systems. NASA will set a target launch date after a successful wet dress rehearsal test.

Work continues inside the Vehicle Assembly Building (VAB) at NASA’s Kennedy Space Center in Florida in preparation for the Artemis I wet dress rehearsal test, currently targeted for next month. Teams have been installing the flight termination system on the rocket and working on the first of a two-part test of the system. For safety, all rockets are required to have a flight termination system that the Space Launch Delta 45 can use to terminate the flight if necessary. Once the rocket and spacecraft systems are verified during wet dress rehearsal testing, the 322-foot-tall rocket will roll back into the VAB for final inspections and checkouts, including the second part of the flight termination system test, ahead of returning to the pad for launch.

In addition to work on the flight termination system, the team is installing instrumentation on the twin solid rocket boosters and core stage, as well as instrumentation needed for the wet dress rehearsal rollout. Artemis I is a flight test, and engineers will capture as much data as possible on the performance of all the systems that are part of the Space Launch System (SLS) rocket and the Orion spacecraft as well as the Kennedy ground systems that support the vehicle during rollout, wet dress rehearsal, and launch. Not only will this be the first integrated flight for SLS and Orion, but it will be the first use of many new ground systems. Thousands of sensors and special instruments will monitor the rocket and spacecraft as they make the four-mile journey to Launch Complex 39B next month. The team is also working to inspect and install thermal blankets on the core stage engine section.

Up next, the team plans to power up the Orion spacecraft as part of testing the flight termination system and then close the spacecraft’s hatch after powering it down.

NASA has updated the schedule to move the combined Space Launch System rocket and Orion spacecraft out of the Vehicle Assembly Building (VAB) to Launch Pad 39B at the agency’s Kennedy Space Center in Florida for testing to no earlier than March 2022.

NASA has added additional time to complete closeout activities inside the VAB prior to rolling the integrated rocket and spacecraft out for the first time. While the teams are not working any major issues, engineers continue work associated with final closeout tasks and flight termination system testing ahead of the wet dress rehearsal.

Teams are taking operations a step at a time to ensure the integrated system is ready to safely launch the Artemis I mission. NASA is reviewing launch opportunities in April and May.

Page 2

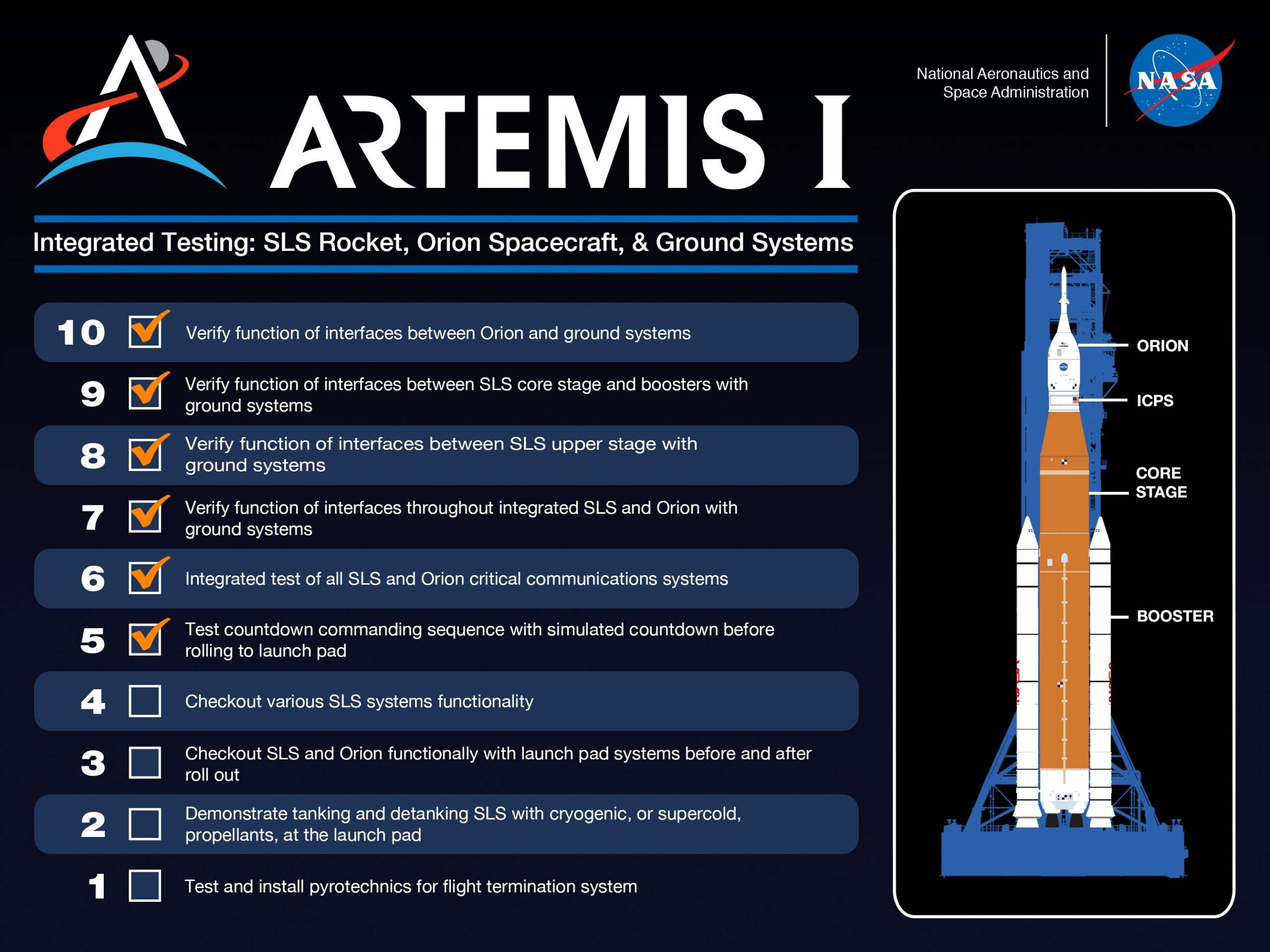

Engineers and technicians successfully completed a second countdown sequencing test on Jan. 24 inside the Vehicle Assembly Building at NASA’s Kennedy Space Center in Florida. This is one of the final tests for the SLS rocket and Orion spacecraft ahead the Artemis I mission, and brings the team one step closer to rolling to the launch pad in mid-February for the wet dress rehearsal test.

Engineers and technicians successfully completed a second countdown sequencing test on Jan. 24 inside the Vehicle Assembly Building at NASA’s Kennedy Space Center in Florida. This is one of the final tests for the SLS rocket and Orion spacecraft ahead the Artemis I mission, and brings the team one step closer to rolling to the launch pad in mid-February for the wet dress rehearsal test.

The test demonstrated the ground launch software and ground launch sequencer, which checks the health and status of the rocket sitting on the pad. The simulated launch countdown tested the responses from the Space Launch System rocket and Orion spacecraft, ensuring the sequencer operates correctly. On launch day, the ground launch sequencer hands off to the rocket and spacecraft, and an automated launch sequencer takes over control of the rocket from ground controllers around 30 seconds before launch.

Up next the team will work to complete the final program specific engineering tests for the Artemis I mission. With the countdown sequencing test complete, Exploration Ground Systems teams will continue doing final checks and closeouts of the Moon rocket in preparation for the wet dress rehearsal test next month. For wet dress rehearsal, engineers will fully load SLS with propellant, and the team on the ground will run through all the pre-launch operations to prepare for the Artemis I launch.

After replacing and testing one of four RS-25 engine controllers, the team conducted several tests to ensure the massive core stage is ready to roll to the launch pad for the wet dress rehearsal ahead of the Artemis I launch. Engineers and technicians tested communication between the flight computers and other core stage systems and slightly moved the engines to practice the gimbaling they will experience during flight.

After replacing and testing one of four RS-25 engine controllers, the team conducted several tests to ensure the massive core stage is ready to roll to the launch pad for the wet dress rehearsal ahead of the Artemis I launch. Engineers and technicians tested communication between the flight computers and other core stage systems and slightly moved the engines to practice the gimbaling they will experience during flight.

All four engine controllers were powered up and performed as expected as part of the Artemis I Core Stage engineering tests. Following the power up, engineers successfully performed diagnostic tests on each controller.

Up next, the team will conduct a second countdown sequencing test to demonstrate the ground launch software and ground launch sequencer, which checks for health and status of the vehicle while at the pad. The simulated launch countdown tests the responses from SLS and the Orion spacecraft, ensuring the sequencer can run without any issues. After the countdown test and final closeouts are complete, SLS and Orion will head to the launch pad for the first time to complete the wet dress rehearsal test.

On Jan. 11, engineers and technicians with Exploration Ground Systems retracted and extended the Orion spacecraft crew access arm as part of ongoing work leading up to the Artemis I wet dress rehearsal targeted for late February.

The arm rotates from its retracted position and interfaces with the Space Launch System (SLS) rocket at the Orion crew hatch location to provide entry and exit for the Orion crew module during operations in the Vehicle Assembly Building and at the launch pad. On crewed Artemis missions, the access arm also provides entry and exit for astronauts. The arm retracts from the Orion spacecraft before launch.

The team continues to complete final testing and closeouts of SLS and Orion. Check back for updates on the agency Artemis blog.

Engineers and technicians continue to complete integrated tests inside the Vehicle Assembly Building at NASA’s Kennedy Space Center as part of the lead up to launch of the Artemis I mission.

Engineers and technicians continue to complete integrated tests inside the Vehicle Assembly Building at NASA’s Kennedy Space Center as part of the lead up to launch of the Artemis I mission.

On Dec. 17, the team completed a communications end-to-end test to ensure the rocket, spacecraft and ground equipment can communicate with the consoles in the launch and mission control centers. This verification of communication systems via radio frequency ensures the launch team will be able to monitor the Space Launch System (SLS) rocket and Orion spacecraft on the ground as well as during flight. The test used an antenna in the VAB, another near the pad that will cover the first few seconds of launch, as well as a more powerful antenna that uses the Tracking Data Relay Satellite and the Deep Space Network.

On Dec. 20, the Exploration Ground Systems team conducted a countdown sequencing test to demonstrate the ground launch software and ground launch sequencer, which checks for health and status of the vehicle sitting on the pad. The simulated launch countdown tested the responses from SLS and Orion, ensuring the sequencer can run without any issues. On launch day, the ground launch sequencer hands off to the rocket and spacecraft and an automated launch sequencer takes over around 30 seconds before launch. Engineers have added a second sequencing test before rollout to account for differences between the emulator and flight hardware identified during the initial test.

Last week engineers and technicians successfully removed and replaced an engine controller from one of four RS-25 engines after the team identified an issue during a power-up test of the rocket’s core stage. Engineers are now performing standard engine controller diagnostic tests and check-outs, including controller power-up and flight software load. Subsequently, the team will work to complete all remaining SLS pre-flight diagnostic tests and hardware closeouts in advance of a mid-February rollout for a wet dress rehearsal in late February. NASA will set a target launch date after a successful wet dress rehearsal test.

SLS will be the most powerful rocket in the world and is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission. With the Artemis missions, NASA will land the first woman and the first person of color on the Moon and establish long-term exploration in preparation for missions to Mars. SLS and Orion, along with the commercial human landing system and the Gateway that will orbit the Moon, are NASA’s backbone for deep space exploration.

NASA’s Space Launch System (SLS) rocket and Orion spacecraft are undergoing integrated testing inside the Vehicle Assembly Building at NASA’s Kennedy Space Center in Florida to ensure they are “go” for launch of the Artemis I mission early next year.

After stacking the Orion atop the SLS rocket, the engineers completed several tests to ensure the rocket and spacecraft are ready to roll to the launch pad ahead of the Artemis I wet dress rehearsal. These tests included ensuring Orion, the core stage, and boosters can communicate with the ground systems and verification testing to make sure all the pieces of the rocket and spacecraft can power up and connect to the consoles in the Launch control Center.

During a recent core stage power test, engineers identified an issue with one of the RS-25 engine flight controllers. The flight controller works as the “brain” for each RS-25 engine, communicating with the SLS rocket to provide precision control of the engine as well as internal health diagnostics. Each controller is equipped with two channels so that there is a back-up, should an issue arise with one of the channels during launch or ascent. In the recent testing, channel B of the controller on engine four failed to power up consistently.

The controller had powered up and communicated successfully with the rocket’s computers during preliminary integrated testing, in addition to performing a full duration hot fire during Green Run testing with all four RS-25 engines earlier this year at NASA’s Stennis Space Center near Bay St. Louis, Mississippi. NASA and lead contractor for the RS-25 engines, Aerojet Rocketdyne, also test all RS-25 engines and flight controllers for Artemis missions at Stennis prior to integration with the rocket.

After performing a series of inspections and troubleshooting, engineers determined the best course of action is to replace the engine controller, returning the rocket to full functionality and redundancy while continuing to investigate and identify a root cause. NASA is developing a plan and updated schedule to replace the engine controller while continuing integrated testing and reviewing launch opportunities in March and April.

Verification testing of the Interim Cryogenic Propulsions Stage is ongoing along with closeouts of the boosters, and parallel work continues with core stage engineering testing. Communication end-to-end testing is underway, and countdown sequence testing will begin as early as next week to demonstrate all SLS and Orion communication systems with the ground infrastructure and launch control center. Integrated testing will culminate with the wet dress rehearsal at historic Launch Complex 39B. NASA will set a target launch date after a successful wet dress rehearsal test.

SLS will be the most powerful rocket in the world and is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission. With the Artemis missions, NASA will land the first woman and the first person of color on the Moon and establish long-term exploration in preparation for missions to Mars. SLS and Orion, along with the commercial human landing system and the Gateway that will orbit the Moon, are NASA’s backbone for deep space exploration.

Materials scientists finished applying the thermal protection system to NASA’s Space Launch System (SLS) launch vehicle stage adapter and moved it to another manufacturing area to finish outfitting the flight hardware for the Artemis II mission.

On Dec. 8, 2021, a NASA transporter moved the adapter which was built at NASA’s Marshall Space Flight Center by lead contractor Teledyne Brown Engineering in Huntsville, Alabama. Teams recently completed applying the spray-on foam insulation that will protect the rocket hardware during flight. Now, crews will outfit the inside of the adapter with platforms that will allow teams to access the inside during assembly with the rest of the rocket. Technicians will also install special systems that allow the adapter and the core stage to separate from the Interim Cryogenic Propulsion Stage, or ICPS. The adapter connects the rocket’s core stage to the ICPS, which provides the power to perform the trans-lunar injection maneuver to send the Orion spacecraft to the Moon. This adapter is for the Artemis II mission that will be the first to return American astronauts to lunar orbit.

A team of NASA and Northrop Grumman engineers fired a 2-foot-diameter, subscale solid rocket booster on Dec. 2, 2021, at NASA’s Marshall Space Flight Center in Huntsville, Alabama. This test, conducted in Marshall’s East Test Area, was the second of three tests supporting the Booster Obsolescence and Life Extension (BOLE) program, which will have an upgraded design to power the evolved configuration of the Space Launch System (SLS) rocket on flights after Artemis VIII.

The BOLE booster will be a larger and more powerful solid rocket motor than the current SLS solid rocket booster. The boosters for the first eight flights of the Artemis program repurpose the steel booster cases and parts from the Space Shuttle Program with an upgraded design. The BOLE booster will implement a composite case design, replace obsolete parts with newer components, and improve the booster’s design and performance.

This test focused on the booster motors, which provide the majority of the power to launch SLS. Unlike previous subscale motor tests, this marked the first time the team could evaluate insulation and nozzle on one motor rather than two configurations, one for the nozzle and one for the insulation. During this subscale test, the motor produced 76,400 pounds of thrust.

The original test design had two segments, each 9 feet long. To get a more characteristic thrust profile, a 4.5-foot-long segment was added to the test article, totaling nearly 28 feet and making this the longest subscale motor tested to date. In addition to the added half segment, a new propellant, aft dome design, and nozzle design are included in the BOLE motor development program that will become part of the Block 2 evolved rocket.

During the test, three different internal case insulation formulations were evaluated in the aft dome. The performance results of these materials will aid in selecting a final formulation for the first full-scale test fire of the BOLE booster. As the team completes the final design for the full-scale motor, this test is an important step in learning how materials will perform at the higher pressure and performance expected for the BOLE motor as compared to current motors.

The third test of the subscale motor is currently scheduled for spring 2022 at Marshall, followed by the first full-scale BOLE motor test, tentatively scheduled for spring 2024 at Northrop Grumman’s test facility in Utah. Northrop Grumman, lead contractor for the booster, helped conduct the Marshall test and will be assisting with data evaluation.

NASA and the U.S. Navy are preparing to head out to sea for the ninth in a series of tests to verify and validate procedures and hardware that will be used to recover the Orion spacecraft after it splashes down in the Pacific Ocean following deep space exploration missions.

NASA’s Landing and Recovery team, managed by Exploration Ground Systems, is heading from the agency’s Kennedy Space Center in Florida to Naval Base San Diego in California where they will have their final certification run for the Artemis I mission.

During the weeklong test, the joint team will conduct simulations that will exercise all the operational procedures, including nighttime, to support certification of team members for the Artemis I mission. The team will practice recovering a test version of an Orion capsule and bringing it into the well deck of a Navy ship, ensuring all personnel are properly trained before the real Orion splashes down.

Orion is the exploration spacecraft designed to carry astronauts to the Moon and destinations not yet explored by humans. It is slated to launch atop NASA’s Space Launch System rocket on its first deep space mission to pave the way for future flights with astronauts.

Teams with Exploration Ground Systems successfully lifted the Orion Spacecraft for the Artemis I mission inside the Vehicle Assembly Building on Oct. 20, 2021. Teams attached the spacecraft to one of the five overhead cranes inside the building and began lifting it a little after midnight EDT. Work is underway to fully secure Orion to the Space Launch System rocket after teams initially placed the spacecraft on top of the rocket earlier today. This operation will take several hours to make sure Orion is securely in place.

Final stacking operations for NASA’s mega-Moon rocket are underway inside the Vehicle Assembly Building at NASA’s Kennedy Space Center as the Orion spacecraft is lifted onto the Space Launch System (SLS) rocket for the Artemis I mission. Engineers and technicians with Exploration Ground Systems (EGS) and Jacobs attached the spacecraft to one of the five overhead cranes inside the building and began lifting it a little after midnight EDT.

Next, teams will slowly lower it onto the fully stacked SLS rocket and connect it to the Orion Stage Adapter. This will require the EGS team to align the spacecraft perfectly with the adapter before gently attaching the two together. This operation will take several hours to make sure Orion is securely in place.

NASA will provide an update once stacking for the Artemis I mission is complete.