Why Rapid Injection Molding represents a breakthrough in Manufacturing.

In today's rapid manufacturing sector, the demand for velocity, efficiency, and economical solutions has never been greater. As businesses endeavor to outpace their competitors, the need for innovative manufacturing processes has become crucial. Swift injection molding has emerged as a revolutionary solution, enabling companies to introduce their products to market more quickly while maintaining high standards and precision. This groundbreaking technique not only enhances the production process but also cuts costs, making it an attractive option for businesses of all scales.

The benefits of accelerated injection molding extend further than mere speed. By utilizing advanced technologies and materials, manufacturers can create complex designs and sophisticated geometries that were previously difficult or labor-intensive to produce. This enhanced capability allows for greater creativity and adaptability in product design, ensuring that companies can meet the continuously shifting preferences of their clients. As we explore the impact of accelerated injection molding, it becomes clear that this method is not just a passing craze but a game changer that is reshaping the future of manufacturing.

Understanding Quick Injection Forming

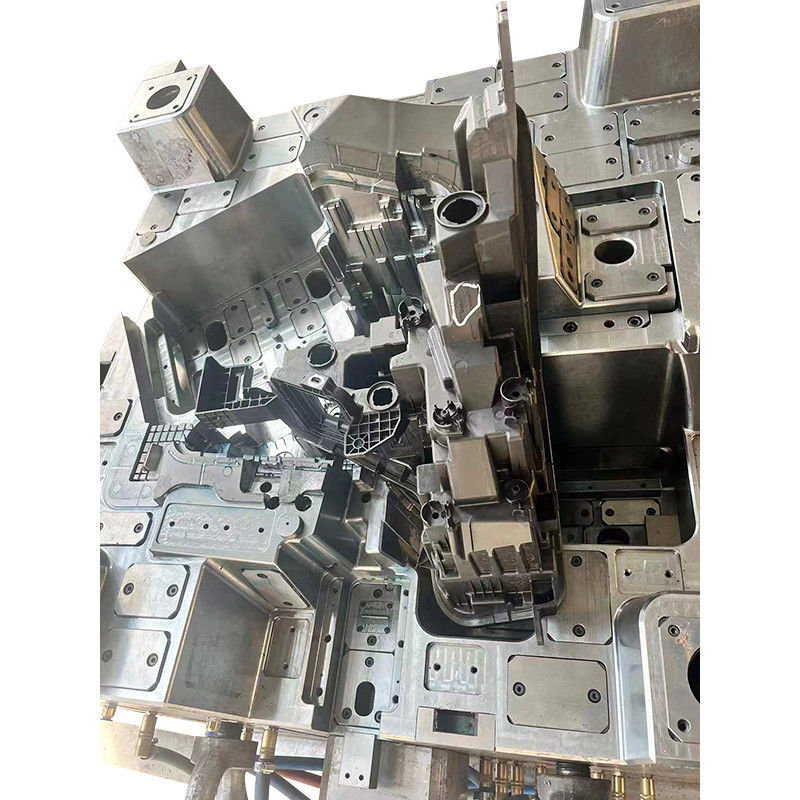

Rapid inject molding represents a manufacturing technique that greatly speeds up the production process for synthetic parts and components. This technique combines traditional injection molding and cutting-edge technology, facilitating quicker turnaround times while maintaining high-quality output. By employing rapid prototyping and specialized materials, manufacturers can create molds at an unprecedented speed, making this technique ideal for applications requiring prompt delivery.

One of the key edges of rapid injection molding lies in its ability to produce small to medium production runs effectively. Traditional injection molding typically requires lengthy setup times and high upfront costs, causing it less feasible for limited quantities. In contrast, rapid injection molding allows companies to produce parts in a more cost-effective way, serving niche markets or testing new designs without significant financial risk.

Additionally, rapid injection molding fosters innovation in product design. With the ability to quickly create molds and parts, designers can iterate and test various models without long delays. This flexibility in the manufacturing process not only hastens development but also encourages collaboration between engineers, designers, and manufacturers, ultimately producing more innovative solutions and better products.

Benefits of Rapid Injection Molding

One of the main benefits of rapid injection molding is its ability to significantly reduce lead times. Traditional injection molding processes can take weeks or even multiple months to set up due to equipment setup and production preparation. In contrast, rapid injection molding makes use of innovative techniques and materials that enhance the manufacturing process. This allows companies to bring products to market much faster, which is vital in today's fast-paced business environment where speed can be a critical competitive advantage.

Another advantage is the cost-effectiveness of rapid injection molding, particularly for mid-scale production runs. With rapid tooling, manufacturers can create molds at a competitive cost and with quicker turnaround times. This cost efficiency encourages innovation, as companies can afford to test various designs or variations without incurring high costs. It allows for more adaptability in product development, enabling businesses to adapt to evolving consumer needs and preferences with effortlessness.

Additionally, rapid injection molding ensures high-quality production standards. The technology used in rapid injection molding is designed to produce parts with exceptional precision and consistency. This level of quality is essential for industries that require rigorous adherence to specifications, such as automotive and medical sectors. Enhanced quality reduces the chance of defects and rework, providing companies with dependable products that meet customer expectations and regulatory requirements.

Uses in Current Production

Rapid injection molding has transformed various fields in current manufacturing by enabling for rapid modeling and product development. Sectors such as car and consumer electronics utilize the quickness and flexibility of this technology to make intricate parts with accuracy. By allowing manufacturers to produce parts in small quantities swiftly, rapid injection molding considerably speeds up the overall product development cycle, allowing companies to introduce their innovations to market faster than previously.

One more key application is in the healthcare industry, where the demand for high-quality, customized components is essential. Rapid injection molding enables the development of intricate and specific designs that meet severe regulatory standards. This feature guarantees that manufacturers can create devices that not only work well but are also customized to meet the unique needs of individuals and healthcare providers without lengthy delays or high costs.

Furthermore, the consumer goods sector has experienced a beneficial influence from rapid injection molding. As industry trends change and consumers seek new products more frequently, manufacturers are pressured to keep up with these demands. Rapid injection molding supports limited production, allowing companies to rapidly test new designs and modify based on customer feedback. This versatility not only enhances product offerings but also bolsters a company's position in an ever more competitive marketplace.