What Does "The Road to Success: Harnessing the Power of Friction Reduction in Transportation" Mean?

Friction Reduction Techniques: A Game-Changer in Industrial Applications

Friction is a organic power that develops when two areas come right into connect with and relocate relative to each other. While it is an vital aspect of daily lifestyle, rubbing can easily likewise be a significant worry in industrial applications. The resistance led to through abrasion can easily lead to improved damage and tear, electricity usage, and decreased performance. To deal with these problem, numerous rubbing reduction approaches have been cultivated that are showing to be game-changers in the industrial industry.

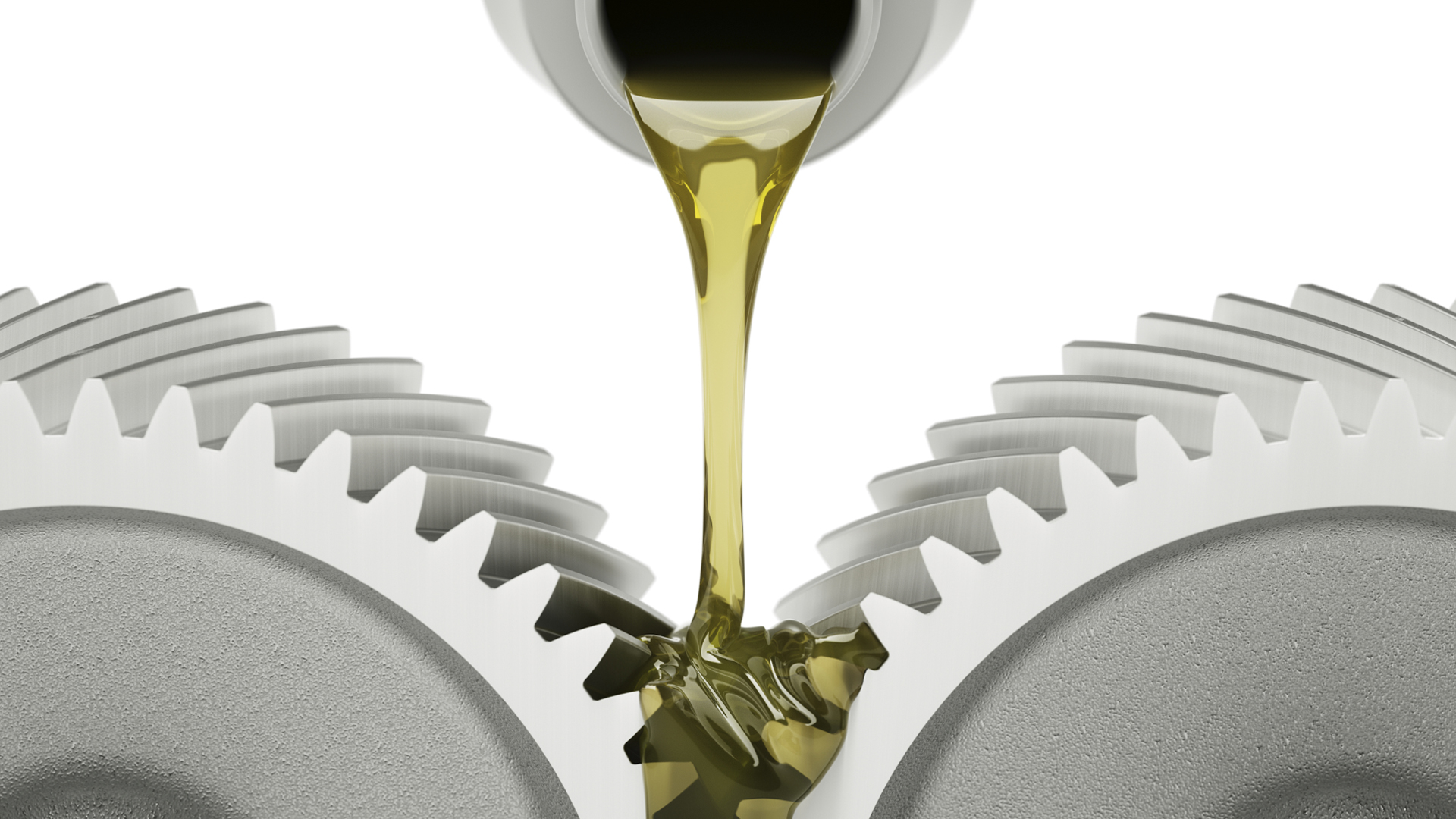

One of the most commonly used techniques for decreasing abrasion is oiling. Lubricating Improved oil flow lubricant are materials applied between two areas to lessen rubbing and put on. They generate a thin movie that splits the getting in touch with surfaces, decreasing straight metal-to-metal contact. This dramatically lowers frictional power and makes it possible for for smoother action. Furthermore, lubricators aid fritter away heat created through abrasion, additionally enhancing functionality and prolonging the life expectancy of equipment.

Different styles of lubes are on call for certain applications. Regular mineral oils, man-made oils, oil, solid lubricators like graphite and molybdenum disulfide (MoS2), and also nanomaterial-based lubes are utilized relying on aspects such as temperature variety, load ability, rate demands, and environmental points to consider.

Another reliable procedure for lessening abrasion is surface customization. Through altering the surface area properties of materials by means of procedures such as finishings or treatments, designers can easily improve their performance in phrases of lowered frictional resistance. Surface area finishings like plastics or ceramics give a preventive level that reduces direct connect with between areas while giving enhanced sturdiness.

Surface area treatments like nitriding or carburizing alter the chemical structure of the surface coating to produce a hardened level along with improved put on resistance. These treatments not only reduce abrasion but also boost the load-carrying ability of parts such as gears or bearings.

Advancements in nanotechnology have additionally led to innovative approaches for reducing friction at the atomic amount. Self-assembling monolayers, for example, include the deposition of a singular level of molecules on a area to create a friction-reducing impact. The accurate plan and residential properties of these molecules allow for enhanced greasing and reduced abrasion coefficients.

In add-on to greasing and surface modification approaches, proper style and component assortment participate in crucial tasks in reducing abrasion in industrial applications. Engineers have to very carefully think about factors such as the option of components, area finishes, geometrical endurances, and operating ailments to minimize frictional losses.

The use of sophisticated materials with reduced coefficients of friction can easily significantly impact performance. For instance, the overview of self-lubricating materials like polymers or compounds along with embedded sound lubricating substances has provided to decreased rubbing in various functions. Furthermore, advancements in tribology research study have led to far better understanding and marketing of interfaces between consulting with areas, resulting in improved efficiency and longevity.

Abrasion decline techniques have far-reaching ramifications all over numerous markets. In auto applications, lowered abrasion translates in to improved fuel performance and lower discharges. In manufacturing processes, lowered wear means much less recovery time for maintenance and improved efficiency. Even small remodelings in abrasion reduction may result in sizable savings over opportunity.

In addition, as fields make every effort towards sustainability objectives, adopting abrasion decrease approaches may contribute to electricity preservation initiatives through minimizing power criteria. This not merely lowers functional expense but likewise markets environmental conservation.

In conclusion, abrasion decline techniques are transforming commercial applications by strengthening effectiveness while lessening damage and energy usage. Oiling procedures using different types of lubricants provide notable advantages by minimizing straight contact between surfaces. Area adjustment procedures enrich functionality with coatings or treatments that affect product residential or commercial properties at the surface area amount.

Innovations in nanotechnology enable exact management over atomic-level communications for enhanced oiling results. Proper style methods combined along with component assortment even further provide to lessening frictional reductions all over numerous sectors.

As innovation continues to advance quickly, it is crucial for sectors to welcome these game-changing approaches for enhancing performance while driving sustainable strategies. Through lowering friction, we may pave the means for a a lot more dependable, successful, and eco friendly future.