Wedge vs Ball Bonding: Which Technique Reigns Supreme?

Introduction

In the area of semiconductor packaging and microelectronic assembly, two dominant wire bonding procedures stand out: wedge bonding and ball bonding. Both tips are important in making sure dependableremember interconnections among chips and substrates, but they arrive with different points, blessings, and programs. This article delves deep into the intricacies of these two twine bonding innovations, proposing a comprehensive diagnosis to make sure which strategy reigns superb in numerous situations. Whether you’re a seasoned engineer or simply establishing your travel in twine bonding science, this guideline will equip you with useful insights.

What is Wire Bonding?Wire bonding is a approach used to create electrical connections among semiconductor devices and their programs. It entails using thin wires—primarily fabricated from gold, aluminum, copper, or silver—that are thermally or ultrasonically bonded to pads on a chip and substrate. The twine bonding job is necessary for high-efficiency electronics because it at once influences reliability, overall performance, and basic software excellent.

The Wire Bonding Process ExplainedThe cord bonding approach should be would becould very well be broken down into a number of key steps:

Preparation: The surfaces of the chip and substrate are wiped clean to cast off any contaminants which could influence bond first-rate. Wire Selection: Depending on the software, engineers desire important resources (gold, aluminum, copper) situated on motives like conductivity and charge. Bond Formation: The chosen strategy (wedge or ball bonding) is carried out the use of really good wire bonding methods. Inspection: Post-bonding inspection guarantees that the connections meet satisfactory principles using varied trying out methods.By working out how cord bonding works, possible savour its serious function in smooth electronics production.

Types of Wire Bonding TechniquesWire bonding encompasses a great number of suggestions tailored for one-of-a-kind programs:

Ball Bonding: Involves forming a ball at the give up of the twine until now creating a bond. Wedge Bonding: Utilizes a wedge-formed software to create bonds with out forming a ball on the quit. Ribbon Bonding: Uses wider ribbons as opposed to common wires for large floor spaces.Each form has its extraordinary set of features that impact functionality in different situations.

Wedge vs Ball Bonding: A Comparative OverviewWhen comparing wedge vs ball bonding thoughts, that is main to analyze their center differences:

1. Bond Formation MechanismBall Bonding:

Begins with heating the wire's cease to kind a small ball. The ball is then pressed opposed to the bond pad utilising ultrasonic electricity to create a mighty attachment.Wedge Bonding:

Uses a wedge device that presses down at the cord without forming a pre-bonded sphere. Bonds are created as a result of mechanical force blended with warmth (thermosonic) or ultrasonic energy. 2. Material CompatibilityEach manner favors one of a kind supplies:

Ball bonding predominantly makes use of gold owing to its optimal conductivity. Wedge bonding can utilize aluminum or copper wires easily. 3. Applications and Industry Use CasesBoth strategies discover their niche across different sectors:

Ball Bonding:

Widely used in microelectronics like IC packaging caused by its compatibility with high-quality pitch functions.Wedge Bonding:

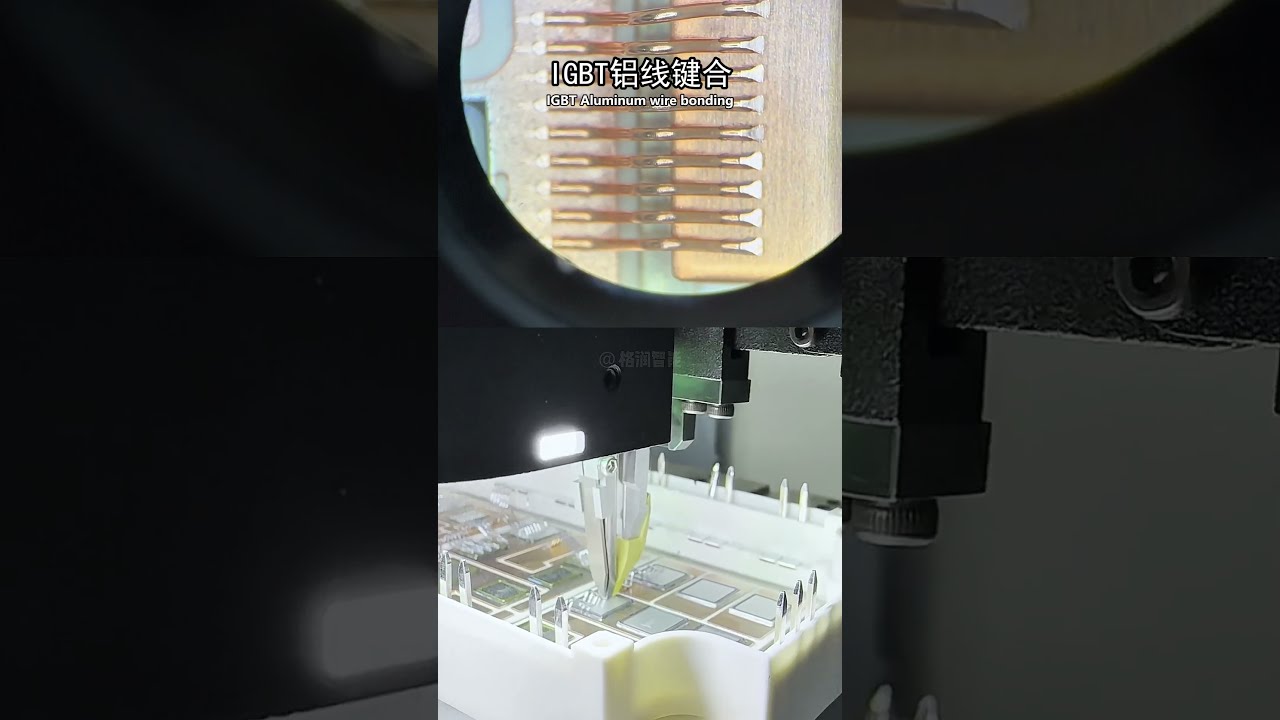

Preferred in electricity modules and automobile electronics the place greater pads are widely wide-spread. 4. Cost ConsiderationCost performs an important position in making a choice on among these processes:

| Feature | Ball Bonding | Wedge Bonding | |------------------|--------------------------|---------------------------| | Material Cost | Higher (Gold) | Lower (Aluminum/Copper) | | Equipment Cost | Typically upper | Generally reduce |

five. Reliability FactorsReliability is paramount in digital functions:

Ball bonds generally tend to reveal larger fatigue resistance under thermal cycling circumstances. Wedge bonds grant gorgeous moisture resistance as a result of their cut back tension stages on pads. Detailed Analysis of Wedge Bonding Process What Makes Wedge Bonding Unique?Wedge bonding sticks out through its fundamental yet successful mechanism for creating stable connections among chips and substrates without needing a pre-bonded sphere:

Key Advantages Material Versatility: Can use different twine models equivalent to aluminum or copper. Lower Stress: Reduces mechanical pressure on pads in contrast to different tricks. Ability for Deep Access: Ideal for stacking dies or operating inside of constrained areas due to its design flexibility. ApplicationsWedge bonding unearths software throughout various industries including:

Automotive electronics Power modules Aerospace components Understanding Wedge Wire Bonding MachinesThe luck of wedge bonding seriously relies on state-of-the-art gear designed specially for this objective:

Ultrasonic Wedge Bonders: Utilize ultrasonic potential for bond formation; flawless for light-weight applications. Thermosonic Wedge Bonders: Combine warmness with ultrasonic power; effective while dealing with greater tricky ingredients like copper. In-depth Look at Ball Bonding Process What Defines Ball Bonding?Ball bonding is ordinarilly preferred in top-density packages in which area is limited yet functionality necessities remain high:

Key Features Fine Pitch Capability: Allows connections at micro-point pitches modifying usual circuit density. Gold Wire Usage: Offers preferable conductivity but comes at an increased materials rate. Established Technology: Has been round longer than wedge bonding making it generally understood by practitioners. ApplicationsBall bonding excels extremely in sectors similar to:

Microelectronics Telecommunications High-frequency RF applications Exploring Ball Wire Bonding MachinesTo succeed in premiere functionality in the time of ball bonding approaches, really good machinery is utilized:

Thermosonic Ball Bonders: Integrate warmness all through bond formation which improves adhesion homes significantly. Automatic Ball Bonder Machines: Facilitate mass creation even as making certain precision in each and every bond created. Evaluating Wire Bond Quality Control MeasuresQuality keep an eye on at some point of either tactics can not be overstated because it quickly influences yield costs and product reliability:

1. Inspection MethodsVarious inspection thoughts ensure that that bonds meet stringent enterprise ideas:

| Inspection Method | Description | |-------------------------|--------------------------------------------------| | Visual Inspection | Manual tests by means of operators making use of magnification | | Pull Test | Evaluates the strength of unique bonds | | Shear Test | Assesses adhesive energy among layers |

Understanding attainable failure modes allows mitigate disadvantages linked to equally technologies:

For Ball Bonds: Incomplete Bonds Oxidation Issues For Wedge Bonds: Heel Cracking Pad DamageImplement rigorous inspections put up-job to catch complications early formerly they have an effect on downstream creation tiers.

Advantages and Disadvantages of Each TechniqueWhen deciding among wedge vs ball bonding, take into accounts those execs and cons that may have an impact on your creation line decisions severely:

Additional reading Advantages of Ball Bonding Fine pitch power allows compact designs a must-have for improved technologies integration. Established methodology capability wide aid supplies are conceivable which include tutorials and films online. Disadvantages of Ball Bonding Higher fees related to gold substances may just deter price range-unsleeping projects. More problematic equipment required when put next to a few picks consisting of wedge approaches. Advantages of Wedge Bonding Lower operational rates owing mostly to less expensive raw ingredients like aluminum or copper wires used on the whole across industries. Enhanced environmental resilience usually interprets into extended reliability over time mainly lower than critical prerequisites undemanding within car functions. Disadvantages of Wedge Bonding Limited applicability bearing on first-class pitch necessities wherein tightly packed circuitry exists demanding change suggestions like ball bonds as a replacement may perhaps yield more advantageous outcome usual from each performance & effectiveness views alike. FAQs About Wedge vs Ball Bonding TechniquesHere are some generally requested questions concerning those two valuable strategies:

1. What’s the standard difference between wedge and ball bonding?The elementary big difference lies in their bond formation mechanism; ball bonding makes use of a melted sphere even though wedge employs direct pressure with out pre-formations resulting in certain blessings based totally on application demands!

2. When will have to I make a choice one approach over every other?If you're looking at compact designs related to great pitches—decide upon ball bonds! However if running inside of strength modules requiring toughness—wedge might serve most productive the following as an alternative!

3. Are there detailed elements merely desirable for one methodology?Yes indeed! Gold works most desirable with balls although aluminum/copper excel below wedges! Make positive you make a choice properly headquartered upon your challenge specifications!

four. How does every technique influence long-time period reliability?Generally communicating—a effectively-carried out ball bond famous most efficient fatigue resistance! While wedges carry super moisture defense ensuring toughness regardless!

five.Who promises preparation components on those processes?Many universities be offering guides alongside quite a few on line structures internet hosting tutorials & webinars centered explicitly upon enhancing skills round those imperative applied sciences!!

ConclusionChoosing among wedge vs ball bonding at last boils down non-public selection dictated via detailed task parameters—concerns consisting of cloth selection,price elements,and wanted overall performance outcomes play pivotal roles influencing this resolution-making strategy immensely!

Both ways have pleasing strengths; for that reason figuring out your program’s enjoyable demands lets in you leverage both method conveniently at the same time maximizing productiveness yields all around production cycles beforehand!