Unveiling the Sparkle: The Versatile Uses of Diamond Blades

Diamond blades are a remarkable tool known for their exceptional cutting abilities across various materials. From concrete to ceramics, diamonds have proven to be an indispensable resource in creating precise and efficient cuts. The versatile nature of diamond blades allows for use in a wide range of industries, making them a valuable asset for professionals and DIY enthusiasts alike. Whether it's construction, masonry, or even home improvement projects, these blades offer unparalleled performance and durability.

Composition and Design

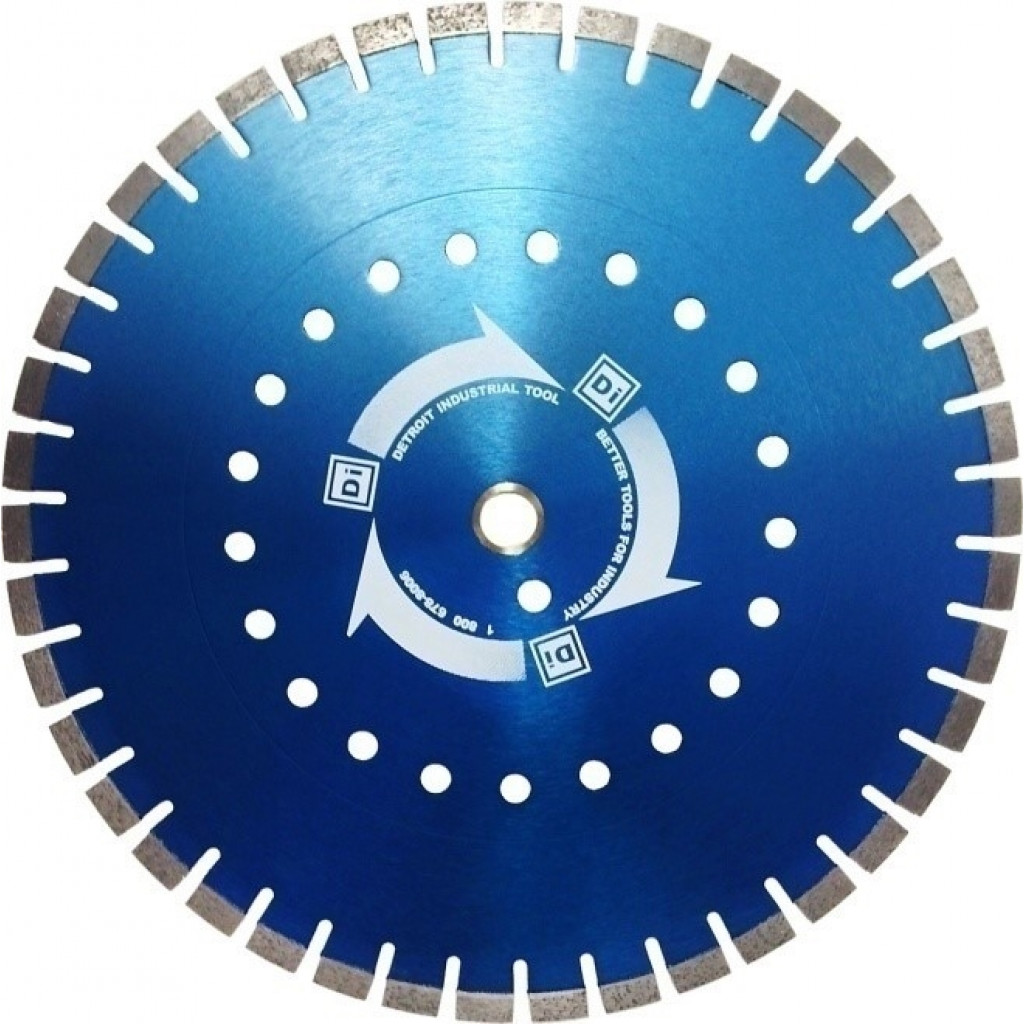

Diamond blades are cutting tools primarily used for cutting various hard materials such as concrete, asphalt, ceramic tiles, and stone. The key component of a diamond blade is its cutting edge, which is embedded with diamond particles. These diamond particles are bonded to the blade's core through a process known as sintering, creating a strong and durable cutting surface.

The design of diamond blade s can vary depending on the specific application they are intended for. Segmented diamond blades are commonly used for cutting concrete and masonry, featuring gullets or slots between segments to improve cooling and debris removal. Continuous rim diamond blades, on the other hand, are ideal for cutting materials that require a smooth finish, such as ceramic tiles or glass.

In addition to the cutting edge design, the core of a diamond blade plays a crucial role in its performance. Cores can be made of different materials such as steel, aluminum, or high-temperature resistant alloys. The core provides stability and support to the cutting edge, ensuring precision and efficiency during cutting operations.

Applications in Various Industries

In the construction industry, diamond blades are essential tools for cutting various materials such as concrete, asphalt, stone, and ceramic tiles. Their precision and durability make them ideal for tasks like creating expansion joints, cutting channels for pipes, and shaping stone countertops.

In the manufacturing sector, diamond blades are widely used for cutting and shaping hard materials like metals, composites, and advanced ceramics. Whether it's cutting metal sheets for fabrication or shaping composite materials for aerospace components, diamond blades offer superior efficiency and accuracy.

In the woodworking industry, diamond blades are employed for tasks that require precision cutting of hardwoods, engineered woods, and laminates. From crafting intricate designs to making precise cuts for furniture pieces, diamond blades play a crucial role in enhancing the quality and efficiency of woodworking processes.

Care and Maintenance

Diamond blades are powerful tools that require proper care and maintenance to ensure their longevity and performance. One key aspect of maintaining a diamond blade is keeping it clean after each use. Residual materials from cutting can accumulate on the blade surface, impacting its cutting effectiveness. Taking the time to clean the blade thoroughly can enhance its cutting efficiency.

Another important maintenance tip for diamond blades is to check for any signs of damage or wear regularly. Inspecting the blade for cracks, segment loss, or uneven wear can help identify potential issues early on. If any damage is detected, it is crucial to address it promptly to prevent further deterioration of the blade's cutting capabilities.

Lastly, storing diamond blades correctly is essential for their preservation. Keeping the blades in a dry environment and ensuring they are protected from moisture and extreme temperatures can prevent corrosion and premature dulling. Additionally, storing the blades in a designated holder or case can prevent accidental damage and prolong their usability.