Unleashing Creativity: Exploring the Diverse Applications of Injection Molding

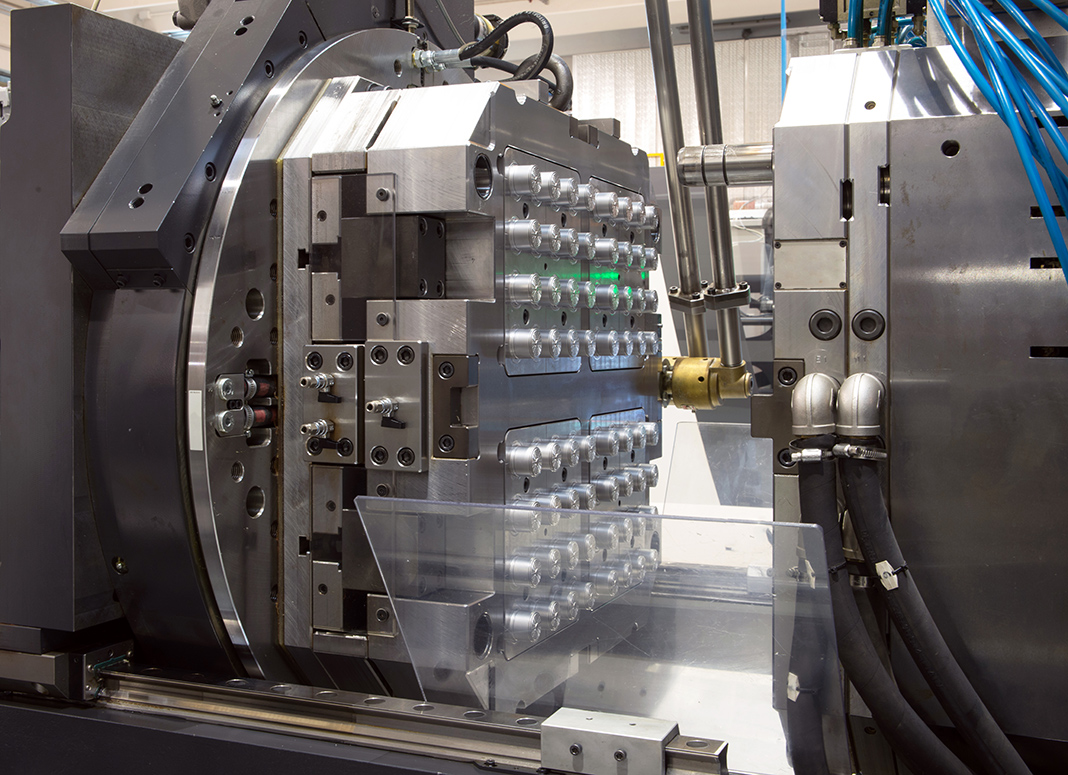

As we delve into the realm of injection molding, we find a world filled with endless possibilities and applications. This versatile manufacturing process has made a significant impact across various industries, from automotive to medical devices, consumer goods, and beyond. The ability to produce intricate and complex parts with high efficiency and precision has positioned injection molding as a cornerstone of modern manufacturing.

Innovators and engineers continuously push the boundaries of what is achievable with injection molding technology, unleashing new levels of creativity that inspire awe and innovation. From creating lightweight and durable components for the automotive industry to crafting custom medical devices that save lives, the applications of injection molding are as diverse as they are impactful. Whether it's producing intricate designs, optimizing production processes, or driving sustainable solutions, injection molding offers a canvas for creativity that knows no bounds.

History of Injection Molding

Injection molding dates back to the late 19th century when cellulosic materials were first injected into a mold to create simple products. Over time, advances in technology and materials have transformed the process into a widely used manufacturing method for producing intricate and detailed parts. The development of high-pressure injection equipment in the mid-20th century further revolutionized the industry by enabling faster and more precise production.

The 1980s saw a significant shift in injection molding with the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) technology. These advancements allowed for greater design complexity and more efficient production processes. As a result, injection molding became a preferred method for manufacturing components across various industries, ranging from automotive and aerospace to consumer goods and medical devices.

In recent years, the ongoing innovation in materials, machinery, and software continues to drive the evolution of injection molding. From 3D printed molds to sustainable bioplastics, the industry is constantly exploring new frontiers. Today, injection molding is not just a manufacturing process but a platform for limitless creativity and endless possibilities in product development.

Innovations in Injection Molding

In recent years, the use of advanced materials in injection molding has revolutionized product design and manufacturing processes. Materials such as biodegradable plastics, high-performance polymers, and composite materials are now being utilized to create products that are not only durable but also environmentally friendly.

Furthermore, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has brought a new level of precision and efficiency to the injection molding process. Manufacturers can now create complex and intricate designs with ease, reducing production time and costs while ensuring consistent quality in every batch.

One of the most exciting innovations in injection molding is the adoption of additive manufacturing techniques, such as 3D printing. This technology allows for rapid prototyping and customization, enabling manufacturers to quickly iterate on designs and produce small batches of products cost-effectively.

Future Trends in Injection Molding

Looking ahead, the injection molding industry is poised for significant advancements in automation and digital technologies. This includes the integration of artificial intelligence and machine learning algorithms to optimize the injection molding process. As automation continues to evolve, we can expect improved efficiency, reduced production costs, and enhanced product quality.

Another key trend on the horizon is the increasing focus on sustainability within injection molding practices. Manufacturers are exploring the use of biodegradable and recycled materials to create more environmentally friendly products. Additionally, there is a growing interest in energy-efficient manufacturing processes and the development of innovative solutions to minimize waste and reduce environmental impact.

In the coming years, the adoption of 3D printing technologies within the injection molding sector is projected to soar. This combination of additive manufacturing and traditional molding techniques offers new possibilities for rapid prototyping, customization, and design flexibility. By harnessing the power of 3D printing, manufacturers can unlock a world of creative possibilities and push the boundaries of what is achievable through injection molding.