Understanding the Importance and Benefits of Shielded Control Cable

Introduction

In the world of electrical and electronic systems, shielded control cables play a crucial role in ensuring reliable and efficient transmission of signals and power. These cables are designed with specific features that make them ideal for applications where protection against electromagnetic interference (EMI) and radio frequency interference (RFI) is essential. In this article, we will delve into the details of shielded control cables, exploring their construction, benefits, applications, and importance in various industries.

1. What is a Shielded Control Cable?

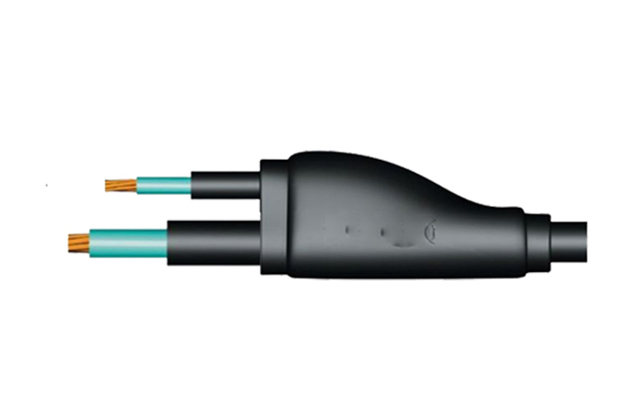

learn more shielded control cable is a type of cable that consists of one or more insulated conductors enclosed within a protective shielding layer. This shielding layer can be made of materials such as aluminum foil, copper braid, or a combination of both. The primary purpose of the shield is to protect the inner conductors from external electromagnetic and radio frequency interference, which can cause signal distortion, data loss, or other performance issues.

2. Construction of Shielded Control Cables

Shielded control cables are typically constructed with the following components:

- Conductors: The conductors are the core elements of the cable responsible for carrying electrical signals or power. These conductors are usually made of copper or aluminum and are insulated to prevent short circuits or signal leakage.

- Insulation: Each conductor is insulated with a dielectric material to provide electrical isolation and protection against moisture and other environmental factors.

- Shielding: The shielding layer surrounds the insulated conductors and acts as a barrier against external interference. The shielding can be made of aluminum foil, copper braid, or a combination of both to provide effective protection.

- Jacket: The outer jacket of the cable provides mechanical protection and insulation for the internal components. It is typically made of PVC, polyethylene, or other durable materials.

3. Types of Shielded Control Cables

There are several types of shielded control cables available, each designed for specific applications and environments. Some common types include:

- Foil Shielded Cable: This type of cable features a thin layer of aluminum foil wrapped around the insulated conductors. Foil shielding is effective against high-frequency interference and is commonly used in data transmission applications.

- Braid Shielded Cable: Braid shielding consists of a woven mesh of copper wires that provides excellent protection against low-frequency interference and offers high flexibility. Braid shielded cables are often used in industrial automation and control systems.

- Combination Shielded Cable: Some shielded control cables combine both foil and braid shielding for enhanced protection against a wide range of interference sources. These cables are suitable for applications with demanding EMI/RFI requirements.

4. Benefits of Shielded Control Cables

Shielded control cables offer several key benefits that make them a preferred choice for critical applications. Some of the main advantages include:

- EMI/RFI Protection: The primary benefit of shielded control cables is their ability to mitigate electromagnetic and radio frequency interference, ensuring reliable signal transmission in noisy environments.

- Signal Integrity: By shielding the conductors from external interference, shielded cables help maintain signal integrity and prevent data corruption or distortion, especially in high-speed communication systems.

- Noise Reduction: Shielded cables reduce the effects of electrical noise and crosstalk, resulting in cleaner signals and improved system performance.

- Durability: The construction of shielded control cables with robust materials ensures long-term reliability and resistance to mechanical stresses, making them suitable for harsh industrial environments.

- Compliance: Shielded cables are often designed to meet industry standards and regulations for EMI/RFI protection, ensuring compliance with safety and performance requirements.

5. Applications of Shielded Control Cables

Shielded control cables find widespread use in various industries and applications where reliable signal transmission and protection against interference are critical. Some common applications include:

- Industrial Automation: Shielded cables are essential for connecting sensors, actuators, and control devices in automated manufacturing systems to ensure precise and uninterrupted operation.

- Robotics: In robotic systems, shielded control cables are used to transmit signals for motion control, feedback, and communication between different components, enabling smooth and accurate operation.

- Data Communication: Shielded cables are commonly employed in networking and telecommunications systems to maintain data integrity and prevent signal loss over long distances.

- Medical Equipment: Shielded control cables are utilized in medical devices and equipment to ensure accurate data transmission and patient safety, particularly in sensitive applications such as MRI machines and surgical instruments.

- Audio/Video Systems: Shielded cables are used in audio and video equipment to minimize interference and maintain high-quality signal transmission for clear sound and picture quality.

6. Importance of Shielded Control Cables

The importance of shielded control cables cannot be overstated, especially in applications where reliable signal transmission is critical. Here are some key reasons why shielded cables are essential:

- Signal Quality: Shielded cables help maintain signal quality by minimizing interference and noise, ensuring that data is transmitted accurately and reliably.

- System Reliability: In industrial automation, robotics, and other critical systems, the use of shielded cables is essential to prevent signal disruptions that could lead to equipment malfunction or downtime.

- Safety: Shielded control cables provide a level of safety by reducing the risk of electrical interference that could pose hazards to operators, equipment, or sensitive electronic devices.

- Regulatory Compliance: Many industries have strict regulations and standards regarding electromagnetic compatibility (EMC) and interference protection. Shielded cables help ensure compliance with these requirements.

- Future-Proofing: As technology advances and electronic systems become more complex, the use of shielded control cables becomes increasingly important to future-proof installations and prevent performance issues as a result of interference.

7. Installation and Maintenance Considerations

Proper installation and maintenance of shielded control cables are crucial to ensuring optimal performance and reliability. Some key considerations include:

- Grounding: Proper grounding of the cable shield is essential to provide an effective path for unwanted signals to dissipate, reducing the risk of interference.

- Routing: Shielded cables should be routed away from sources of electromagnetic interference, such as power cables, motors, and other high-voltage equipment, to minimize the risk of signal degradation.

- Inspection: Regular inspection of shielded cables for damage, wear, or corrosion is important to identify potential issues early and prevent signal loss or system failures.

- Compatibility: When selecting shielded cables for specific applications, it is important to consider factors such as cable length, impedance, and connector compatibility to ensure optimal performance.

8. Conclusion

Shielded control cables play a vital role in ensuring the reliable and efficient operation of electrical and electronic systems by providing protection against electromagnetic and radio frequency interference. With their ability to maintain signal integrity, reduce noise, and enhance system performance, shielded cables are indispensable in a wide range of applications across industries such as industrial automation, robotics, data communication, and healthcare. By understanding the construction, benefits, applications, and importance of shielded control cables, professionals can make informed decisions when selecting and installing cables for their specific requirements.