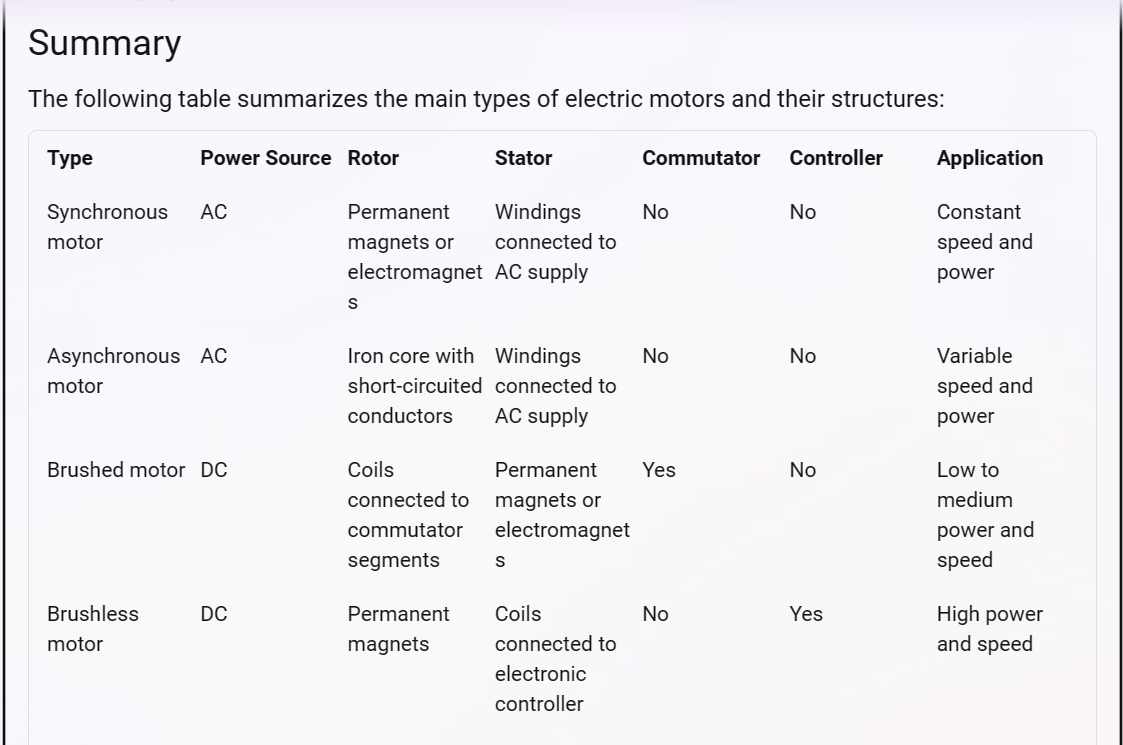

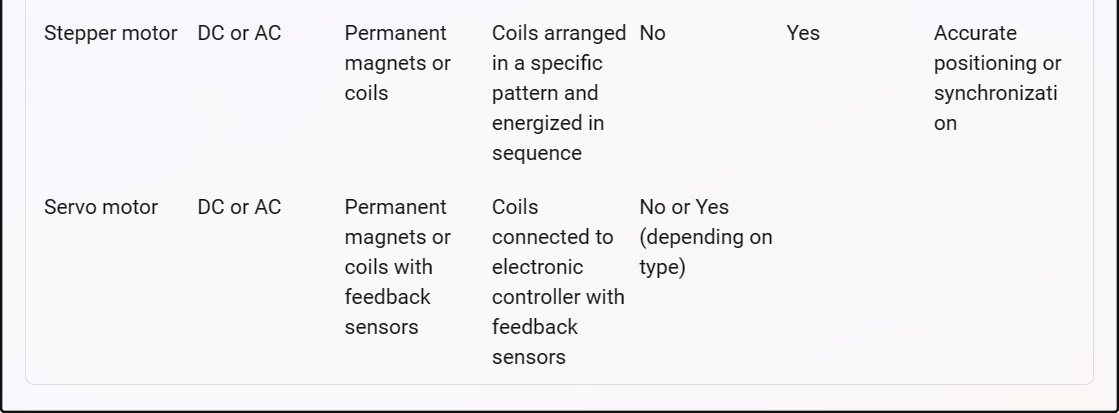

Types of Electric Motors and Their Structures

Bing AIAn electric motor is a device that converts electrical energy into mechanical energy by using the interaction of magnetic fields and electric currents. Electric motors can be classified by various criteria, such as the source of electric power, the type of motion output, the construction of the motor, or the application of the motor. In this article, we will briefly introduce some of the common types of electric motors and their structures.

AC Motors

AC motors are electric motors that are powered by alternating current (AC) sources, such as the power grid or inverters. AC motors can be further divided into two main categories: synchronous and asynchronous.

Synchronous Motors

Synchronous motors are AC motors that rotate at a constant speed that is synchronized with the frequency of the AC supply. Synchronous motors have a rotor that contains permanent magnets or electromagnets that create a constant magnetic field. The stator has a set of windings that are connected to the AC supply and produce a rotating magnetic field. The rotor aligns itself with the stator’s magnetic field and rotates along with it.

Synchronous motors are highly efficient and have precise speed control. They are used for applications that require constant speed and power, such as clocks, generators, compressors, pumps, etc.

Asynchronous Motors

Asynchronous motors are AC motors that rotate at a speed that is slightly less than the synchronous speed determined by the frequency of the AC supply. Asynchronous motors have a rotor that consists of a cylindrical iron core with conductors placed in slots around the surface. These conductors are short-circuited by end rings at both ends of the rotor. The stator has a set of windings that are connected to the AC supply and produce a rotating magnetic field. The rotating magnetic field induces an electric current in the rotor conductors, which in turn creates a magnetic field in the rotor. The rotor’s magnetic field interacts with the stator’s magnetic field and causes the rotor to rotate.

Asynchronous motors are simple, robust, and inexpensive. They are widely used for applications that do not require precise speed control, such as fans, blowers, pumps, conveyors, etc.

DC Motors

DC motors are electric motors that are powered by direct current (DC) sources, such as batteries or rectifiers. DC motors can be further divided into two main categories: brushed and brushless.

Brushed Motors

Brushed motors are DC motors that have a commutator and brushes to switch the direction of current in the windings. Brushed motors have a rotor that contains coils of wire that are connected to the commutator segments. The stator has permanent magnets or electromagnets that create a fixed magnetic field. The brushes are spring-loaded contacts that press against the commutator segments and provide electrical connection to the external circuit. As the rotor rotates, the brushes switch the polarity of current in the coils, which causes the rotor to keep rotating.

Brushed motors are simple, cheap, and easy to control. They are used for applications that require low to medium power and speed, such as toys, tools, appliances, etc.

Brushless Motors

Brushless motors are DC motors that do not have a commutator or brushes. Instead, they use an electronic controller to switch the direction of current in the windings. Brushless motors have a rotor that contains permanent magnets that create a constant magnetic field. The stator has coils of wire that are arranged in a specific pattern and connected to the electronic controller. The controller senses the position of the rotor and switches the current in the coils accordingly, which causes the rotor to rotate.

Brushless motors are more efficient, reliable, and durable than brushed motors. They are used for applications that require high power and speed, such as drones, electric vehicles, industrial machines, etc.

Special Purpose Motors

Special purpose motors are electric motors that have specific features or functions that make them suitable for certain applications or environments. Some examples of special purpose motors are:

- Stepper motors: These are electric motors that can move in discrete steps by energizing different coils in sequence. They can provide precise position and speed control without feedback sensors. They are used for applications that require accurate positioning or synchronization, such as printers, scanners, robots, etc.

- Servo motors: These are electric motors that can rotate within a limited range and maintain a desired position or speed with feedback sensors and controllers. They can provide high torque and fast response. They are used for applications that require precise motion control or force feedback, such as robotic arms, cameras, CNC machines, etc.

- Universal motors: These are electric motors that can operate on both AC and DC sources. They have a series-wound configuration, where the stator and rotor windings are connected in series. They can provide high power and speed, but have low efficiency and durability. They are used for applications that require portability or variable speed, such as vacuum cleaners, blenders, drills, etc.

- Hysteresis motors: These are electric motors that use the property of hysteresis to create torque. They have a rotor that is made of a hard magnetic material that retains its magnetization after being exposed to a magnetic field. The stator has a single-phase winding that produces an alternating magnetic field. The rotor’s magnetization lags behind the stator’s magnetic field, which creates a torque that rotates the rotor. Hysteresis motors are quiet, smooth, and have constant speed. They are used for applications that require low noise or vibration, such as clocks, record players, etc.