Tube Id

⚡ 👉🏻👉🏻👉🏻 INFORMATION AVAILABLE CLICK HERE 👈🏻👈🏻👈🏻

You are here: Home1 / Products2 / TUBEINSPECT system

for high-precision tube ID and OD metrology

NOVACAMTM TUBEINSPECTTM system is a modular, non-contact optical measurement system that provides micron-precision 3D measurements of tube, cylinder or barrel interiors and exteriors. Its small-diameter side-looking probe reaches inside tubes to acquire their complete inside geometry.

captions settings, opens captions settings dialog

captions off, selected

Beginning of dialog window. Escape will cancel and close the window.

Text

Color

White

Black

Red

Green

Blue

Yellow

Magenta

Cyan

Transparency

Opaque

Semi-Transparent

Background

Color

Black

White

Red

Green

Blue

Yellow

Magenta

Cyan

Transparency

Opaque

Semi-Transparent

Transparent

Window

Color

Black

White

Red

Green

Blue

Yellow

Magenta

Cyan

Transparency

Transparent

Semi-Transparent

Opaque

Font Size

50%

75%

100%

125%

150%

175%

200%

300%

400%

Text Edge Style

None

Raised

Depressed

Uniform

Dropshadow

Font Family

Proportional Sans-Serif

Monospace Sans-Serif

Proportional Serif

Monospace Serif

Casual

Script

Small Caps

In this video, the TUBEINSPECT system probe scans both the inside and the outside of a metal barrel fixed in a spinning chuck.

Note: If the cylinder you need to inspect cannot be spun on a rotational stage as done in this video – no problem – simply check out NOVACAM BOREINSPECT system that features a rotational scanner probe.

Measurements

Optical, non-contact, non-destructive

High speed: Up to 100,000 3D point measurements per second

2D and 3D surface and subsurface characterization; diameter, circularity, cylindricity, runout, taper, distortion, straightness

High-aspect-ratio features: undercuts, threads, grooves, cross-holes

Sub-micron resolution and excellent sensitivity and measurement repeatability

Imaging

Line profiles

3D images of internal and external surfaces

Height and intensity images of “unfolded” surfaces

Cross-sections of semi-transparent materials

Deviation maps

Benefits

Easily integrated in lab, shop, or fully-automated inspection setups.

Reduces inspection cycle time: up to 100,000 measurements per second are obtained, each representing a 3D topographic point

Flexible options for evaluating inspected parts: measured features can be compared to CAD drawings or to a user-defined set of locations, nominals, and tolerances

Simple scan definition and execution: The scanning sequence is defined once by teaching the system with a joystick. The scanning sequence can later be executed with the push of a button.

Time-saving automated reporting: Following a scan, go-no-go reports can be produced, and results logged in a manner compatible with industry-standard mechanisms

Easy part handling: The part fixture is selected to make handling easy and to ensure good repeatability

Adaptable to harsh environments

No consumables are needed: Optical probes do not come in contact with the measured samples, and therefore do not wear out like contact probes. Accidental damage is rare−probes are designed to be rugged.

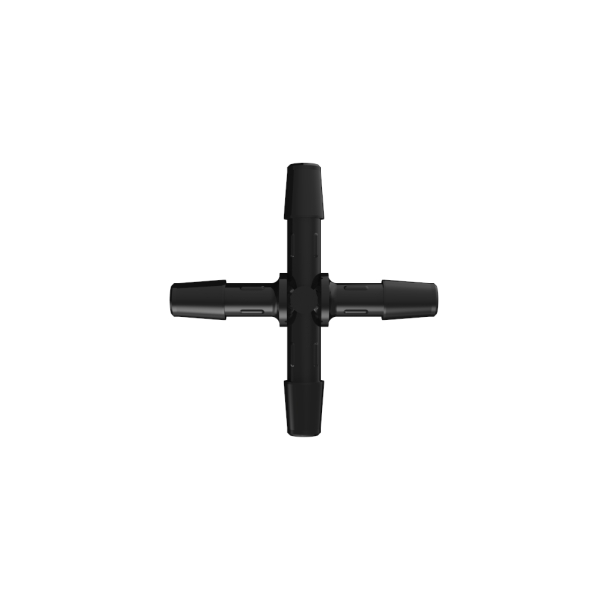

Measurement, visualization, and inspection of ID and OD surfaces of:

Gallery (click images for close-up)

Mounting and scanning the tubular part

Wide range of data analysis options

The TUBEINSPECT system comes with NOVACAM high-performance data acquisition software, which is PC Windows®-based and user-friendly for scan programming.

The system simultaneously generates 3 data sets from the same scan: 3D point cloud, light intensity image, and height image. The height and light intensity images facilitate defect detection. STL file format is also available.

ID measurements are generated in three formats: 3D point cloud, intensity map, and height map.

For full GD&T analysis of measured parts, a turnkey solution is available with PolyWorks InspectorTM metrology software that may be purchased with the system.

Example of ID automated GD&T report with pass and fail

3D data analysis of ID measurements using PolyWorks Inspector. Here the 3D data is being viewed as a deviation map.

Visualizing the scan data may be accomplished by importing the data into various third party visualization and numerical analysis software, such as PolyWorks Inspector, Geomagic, ImageJ, SolidWorks, Octave, MatLab, Mathematica, IDL, or IGOR Pro.

Deriving application-specific measurements from the 3D point cloud is available through a selection of in-house and third party software. Novacam supports the following options:

Dimensional measurements (GD&T parameters)

PolyWorks Inspector (turnkey solution)

Geomagic

* Novacam offers the option of custom data processing, reporting, and defect detection programs that can be written based on client requirements.

An application programming interface (API) is available for system integrators and OEMs to accommodate a wide variety of online and offline applications. Exported results may be integrated with data loggers and SPC software.

NOVACAMTM TUBEINSPECTTM system is a fiber-based modular system that comprises 1) Optical side-looking probe, 2) MICROCAMTM interferometer, 3) Inspection station, 4) PC, 5) Motion controller(s) (not shown) and, optionally, 6) multiplexing hardware (not shown).

The inspection capabilities of the TUBEINSPECT system are determined jointly by its components:

The side-looking optical probe reaches inside the spinning tube to scan its complete inside geometry in a spiral pattern. The same probe may be used to measure a range of tube diameters. The same probe may be moved to the OD measurement position to scan the outside of the tube.

Note that the side-looking probe does not need to be positioned at the centerline of the tube. The probe simply needs to be lowered into the tube at a constant distance from the tube’s ID surface.

*Custom probes with non-standard diameters (such as ø8.8 mm or ø30.5 mm), lengths, spot sizes, and light beam angles (i.e., different from the standard 90°) are built upon request. Custom probes for extreme temperatures, high pressures, or other hostile environments are also built upon request.

**Maximum probe length may be limited by mechanical constraints. Probes as long as 2 m have been built.

NOVACAM MICROCAM interferometer provides the light source to the optical probe and processes the optical signal received from the probe. The probe and the interferometer are connected with an optical fiber

Size of interferometer enclosure box

(depth x width x height)

4U rackable enclosure

445 x 445 x 178 mm

depends on selected probe parameters,

see table "Standard probe characteristics" above

Light spot size (Lateral [XY-axis] resolution)

2.2 - 146 µm, depends on selected probe parameters,

see table "Standard probe characteristics" above

0.5 - 100 mm for standard probes

up to 1 m for non-standard probes

Thickness measurement range (in Air, IR = 1.0)

Typical materials for thickness measurements

glass, polymers, multi-layer films, coatings, plastics, silicone, liquids, specular or non-specular

*To further increase maximum scanning depth, a mechanical displacement axis is available.

Inspection station configurations are application-dependent and can be supplied by Novacam. Fixturing for the part is not included.

For lab and shop floor inspection, TUBEINSPECT system inspection stations typically include probe displacement in 2, 3, or 4 axes, and a motorized spinning fixture for the inspected tube. Granite tables are optionally available and recommended for some applications.

For automated inline industrial inspection, TUBEINSPECT probes may be integrated with precision stages, third-party CMMs (coordinate-measuring machines), CNC (computer numerical control) machines, or robots to support high-volume continuous flow manufacturing.

Alternative inspection station configurations:

A) TUBEINSPECT system in a “probe-on-top” configuration integrated with a 4-axis inspection station

To measure the tube ID, the side-looking probe is lowered inside the tube that is fixed and spinning on a rotational stage. To measure the tube OD, the rotational stage is first moved on a linear stage to an OD-scanning position. In this position, the tube is spun again, and the probe scans the OD while descending along the outside surface.

Benefits of this configuration: With just one automated scanning sequence, the tube can be measured and characterized both on the inside and outside.

B) TUBEINSPECT system in a “probe-below” configuration

With this setup, the rotational stage with the tube fixture are on top of the granite table, while the probe displacement stages and the probe are enclosed below the inspection table. The probe enters the spinning tube from below, through a hole drilled in the granite.

Benefits of this configuration: Unintended operator contact with the probe is prevented in a shop environment.

TUBEINSPECT system in a bottom probe configuration

Probe entering a tube from below the inspection table

The TUBEINSPECT system comes with a PC, monitor, mouse, and joystick.

Motion controllers are included. Depending on the number of additional motion axis required, the motion controller(s) are housed in a 2U, 3U, or 4U rackable enclosure.

Optical switches are available for multiplexing up to 8 probes to a single MICROCAM interferometer. Multiplexed probes may be used one at a time. This option brings additional return on investment (ROI) to many installations.

A standard configuration of the TUBEINSPECT system includes:

MICROCAM systems feature an in-probe red laser pointer (650 nm wavelength) for alignment purposes.

MICROCAM systems are Class 1M Laser products, with < 20 mW of infrared and < 5 mW of in-probe laser pointer.

How long does it take to scan a tube with TUBEINSPECT system?

Can TUBEINSPECT system measure internal dimensions of cavities that are not tubular in shape?

Is the TUBEINSPECT system easy to use?

Is the system able to work right on production floor?

Can TUBEINSPECT system give us automated measurements and reports?

I noticed the tube spins around the probe. Can any runout of the chuck affect the scan data?

Does the TUBEINSPECT system probe have to be on the centerline of the tube when measuring the tube ID?

The probe simply needs to be lowered into the tube at a constant distance from the tube’s ID surface.

Contact us or request free sample analysis to see if the TUBEINSPECT system is suitable for your application

HAVE QUESTIONS ABOUT OUR METROLOGY SYSTEMS? INTERESTED IN A PRICE QUOTE?

Our experienced sales team is ready to help you find the best metrology solution to meet and exceed your inspection goals.

AUTOMATE 2022 – Detroit, MI, USA

June 6-9, 2022

IMTS 2022 – Chicago, IL, USA

Sep 12-17, 2022

Novacam Technologies Headquarters

277 Lakeshore Road, Suite #04

Pointe Claire, Quebec, H9S 4L2

CANADA

E-mail: info@novacam.com

Tel. US & Canada: 1-866-694-4002

Tel. international: +1-514-694-4002

This site uses cookies to improve the user experience. By continuing to browse our site, you consent to our use of cookies.

We may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, you cannot refuse them without impacting how our site functions. You can block or delete them by changing your browser settings and force blocking all cookies on this website.

These cookies collect information that is used either in aggregate form to help us understand how our website is being used or how effective our marketing campaigns are, or to help us customize our website and application for you in order to enhance your experience.

If you do not want that we track your visist to our site you can disable tracking in your browser here:

Please enable this feature in your browser settings and reload the page.

We also use different external services like Google Webfonts, Google Maps and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Click to enable/disable Google Webfonts.

Click to enable/disable Google Maps.

Click to enable/disable video embeds.

You can read about our cookies and privacy settings in detail on our Privacy Policy Page.

Check to enable permanent hiding of message bar and refuse all cookies if you do not opt in. We need 2 cookies to store this setting. Otherwise you will be prompted again when opening a new browser window or new a tab.

Click to enable/disable essential site cookies.

Exchanger Resortation -

Tube ID Coating

Exchanger Resortation - Tube ID Coating

Exchanger restoration using tube ID coating has its origins in a power plant project in the early 1990s. Tube ID coating was successfully used to mitigate unexpected corrosion of a condenser bundle; the restoration was a cost-effective option to a bundle retube and returned generation capacity. Since that project Curran has applied thin film tube ID coating for condenser and heat exchanger tube repair at industrial plants across the globe.

Curran International heat exchanger and condenser repair uses engineered polymers, and expert applications to restore exchangers to reliable service. Complete turnkey solutions are designed to inhibit alloy tube fouling, mitigate corrosion and deposit pitting, and provide a barrier to MIC attack.

Important to the integrity of tube ID coating application is tube ID cleaning, Curran developed tools and methodology to more efficiently clean full length tube IDs using dry abrasive. Curran can achieve NACE 1 (SSPC-SP5) “white metal” cleanliness down small diameter tube IDs of any exchanger length.

Tube ID coating requires that applications be uniform, homogeneous, and pass a holiday spark test to assure coating continuity. Curran has multiple application techniques to deliver high functionality protective coatings to full circumferential ID. Thin film coating applies a protective-inert barrier between the water and reactive substrate; pitted tubes are “repaired” and protected from new corrosion.

Curran is applying solutions

Tube ID coatings reduce fouling and boundary layer drag

Reduced pressure drop, optimized tube ID flow

Eliminate precipitates, mineral scaling, fouling

Resist corrosion under deposits

The Curran tube ID coating method has been deployed for in-situ condenser applications globally, and application systems enable tube ID coating in exchangers with limited work area. Curran can provide installation of tube end ferrules as part of a coating repair of condensers in high velocity, high turbidity water services where a sacrificial alloy repair is needed.

Contact Curran about in-service exchanger maintenance and restoration using thin film coatings, tube end ferrules and alloy liners.

Curran International

4610 Vicksburg Lane

Dickinson,TX 77539

Telephone: +1 281 339 9993

FAX: +1 281 339 9994

Alexander Barre

E-mail: abarre@curranintl.com

WBENC – Women’s Business Enterprise National Council

Louisiana State Contractors License

SEO Services by Essential Information Technologies

Pregnant Brunette

Fucking Hairy Older Pussies

Brazzers Porno 1080p

New Omegle 2021 Mini Model Forum

Silver Stars Porn

Thomas C. Wilson - Tube ID Smart Chart

Tube ID and OD measurement & 3D Metrology | Novacam

TUBEINSPECT: Tube ID & OD High-Precision 3D Measurements ...

Tube ID Coating | Exchanger Resortation | Curran International

Tubeid.net : TubeID.Co - Free Download, Streaming, Youtube ...

TubeID.Co - Free Download, Streaming, Youtube Converter ...

Tube ID... Brimar? | Page 2 | The Gear Page

My tube vids - Free porn videos.

Correct Tubes Expansion | KRAIS Tube&Pipe Tools

Hot Videos - DTube

Tube Id

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

%2520copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

+copy.jpg)

.jpg+copy.jpg)

2%2520copy.jpg)

+copy.jpg)

+copy.jpg)

-600x688.png)