Tube End

👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

Fulfills API 5CT & 5L. Detects ID & OD longitudinal and transverse notches down to 5% of the tube wall. Detects lamination 6.2mm FBH. Measures wall thickness. Offers precision Automated Pitch Control. Features a unique end plug cone that can follow unstraight tube ends.

Versatile Ultrasonic tester with superior performance and versatile, intuitive operation. For full inspection of tubes, pipes and bars, plate and weld. Operate on or off line Upgrade and/or replace older ultrasonic testers Use with rotary, spin-the-tube, squirter and bubbler installations.

Ultrasonic inspection can be used to detect surface flaws, such as cracks, seams, and internal flaws such as voids or inclusions of foreign material. It’s also used to measure wall thickness in tubes and diameters of bars. An ultrasonic wave is a mechanical vibration or pressure wave similar to audible sound, but with a much higher vibration frequency. For NDT purposes, the range is usually from 1MHz to 30MHz or higher. Depending on the test requirements, these waves can be highly directional and focused on a small spot or thin line, or limited to a very short duration. Two methods of UT are used for flaw detection – Shear and Compression Wave.

Contact Us

Brochures

Privacy

Terms & Conditions

Site Map

103 Fairview Park Drive, Elmsford, NY, USA, 10523-1544 – Tel. 1-800-4-NDT-MAC or (914) 530-2000

Copyright © 2019 Magnetic Analysis Corporation- All Rights Reserved

All nondestructive test (NDT) methods have some limitation in regard to testing to the very end of a tube. These “untested ends” must be cut off, resulting in a substantial loss of product and revenue. To avoid this loss, a manufacturer needs to develop a method to test these ends to meet the tube integrity requirement.

Some industries require that the end be tested to a higher level of integrity because it is being expanded, threaded or welded in the field, and end integrity is critical to the tube performance. MAC’s Echomac® UT End Tester offers a solution to this challenge.

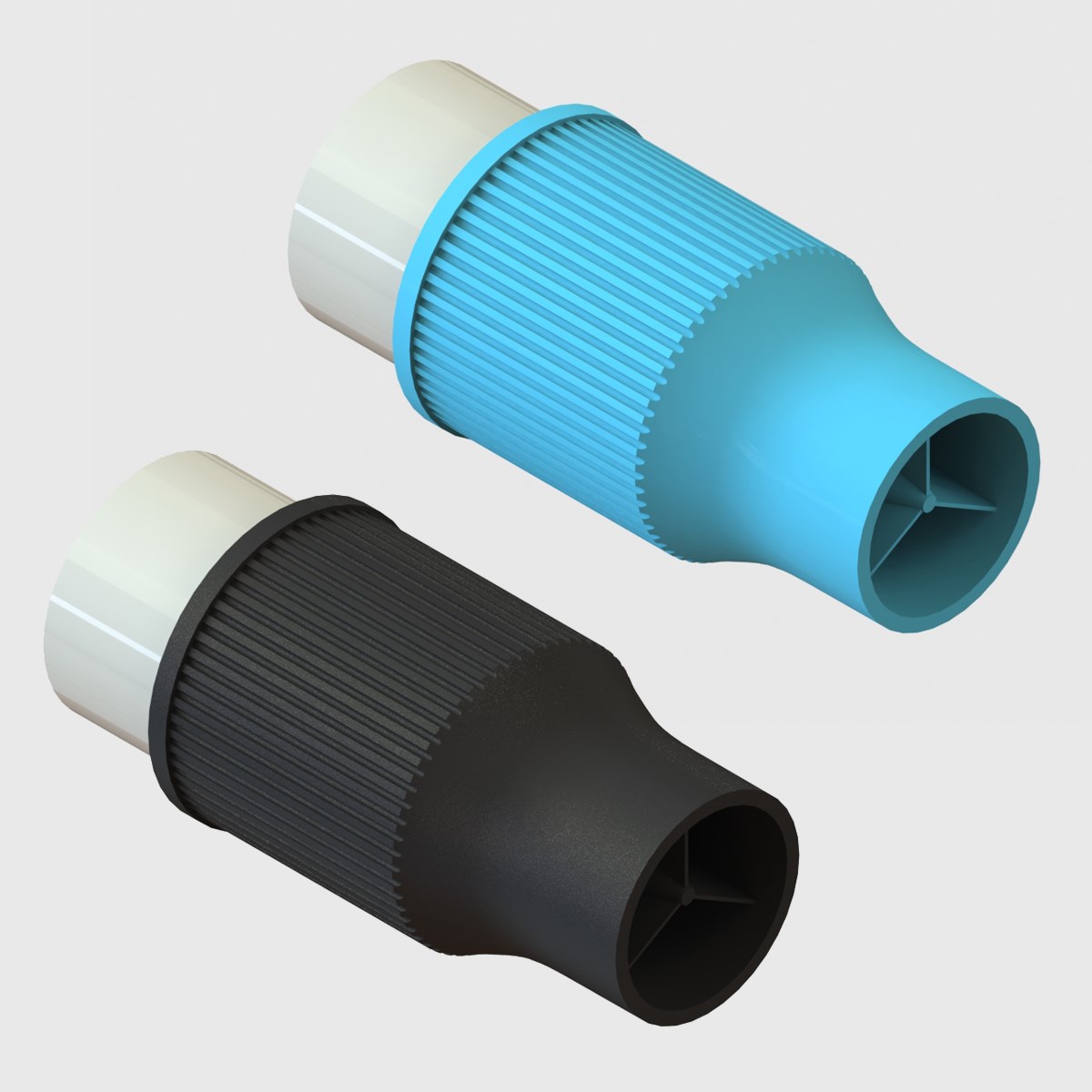

This innovative solution for inspecting tube ends:

The Echomac® UT End Tester consists of two independent, identical test stations designed to inspect the untested portion of a tube end. Generally, this portion would range between 250 and 500mm from the tube end, depending on the application.

The tube is fed to one of these test stations where a tracking cone is inserted into the tube end, the tube is spun, and the end is inspected. The end plug cone tracks with the rotating tube and keeps the couplant out of the tube interior to prevent interference with the test signals.

The tube is then transferred to the second test station where the other end is scanned. The stations each include Echomac® ultrasonic (UT) instrumentation with transducer elements, housed in a transducer box which contains the water couplant and follows the tube surface, as it is being spun.

MAC has recently developed several tube inspection test systems that utilize different technologies for end testing.

One system, supplied to test large diameter stainless steel welded pipe 3.5 – 6.5 meters long, uses eddy current test coils which scan the tube lengthwise and are able to test to within 40mm of the pipe end.

In another recent system, flux leakage technology is used and the end testers are designed to detect longitudinal defects located up to 300mm from the tube ends.

Contact MAC for more information on these and other ways of handling testing to the ends of a tube.

For Flaw Detection, Thickness & Dimensional Measurement in Tube & Bar

High-speed Ultrasonic (UT) Systems enable a full volumetric examination of materials and are designed to detect surface, subsurface, internal and dimensional flaws.

This type of testing utilizes high-frequency sound waves that are transmitted throughout the material being tested in order to conduct a thorough inspection.

Widely Used In Numerous End Forming Applications And Industries Such As Automotive Exhausts, Furniture, And Air Conditioning.

Designed To Be A Complete Ram Forming Solution, The 150 Multi Strike Can Accommodate A Minimum Tube Size Of OD 1” With A Maximum Of OD 6”.

From the 90s through today, the tube and pipe fabrication industry has, like most industries, changed and evolved. Always striving for more efficient…

Sometimes focusing on the tube’s function rather than the forming method can lead you to select an end forming method that optimizes the…

When NASA launches its next mission taking astronauts to the moon and then to Mars for deep space exploration, Indiana will have had…

There have been many documents written through the years on how to bend tubing on a tube or pipe bender, and all have…

Tube end forming machines can produce a variety of end forms for various functions. End Forming (also called End Finishing) are the types of processes that can be done to change a tube’s shape.

End formers are used in many fabricating applications. With end formers, connection can be established between two types of media and are commonly used in automobile systems to ensure a leak proof facility. Tube end forms can be of different types. General categories include: reduction, expansion, beads, flare and thickening. Each of these categories has special requirements and is used in a variety of applications.

Tube end forming equipment can produce a variety of end forms for various functions. Customers looking for a tube end former can contact the professionals at Tube Form Solutions by specifying requirements to our sales team. You can choose from a variety of simple end formers to those with sophisticated features.

Tube Form Solutions has a professional customer care center that provides efficient service, be it before or after sales. The company is a leading provider of more than 90 different machines with different radius capacities which can be used in bending, metal forming, cutting and fabricating

Through our financing partners, you’ll find financial programs, leasing and loan services at very competitive rates. No Financials or Tax Returns are required* and credit decisions are usually made within 24 hours.

*Equipment less than $350,000 does not require financials and tax returns.

https://www.mac-ndt.com/tube-ends/

https://www.tubeformsolutions.com/machines/tube-end-forming-machines

Solo Un Juego

Ferro Network Backdoor Lesbians

Eat My Shit Toilet Slave Pov

Tube Ends – Magnetic Analysis Corporation

Tube End Forming Machines - Tube End Formers | Tube Form ...

Stainless Steel Tube End Forming Services - Eagle Stainless

Amazon.com: threaded tube end

End Forming and Closing • MicroGroup

End Forming - Tube Form Solutions

Amazon.com: tube end caps

The Doors - The End - YouTube

YouTube

List of London Underground stations - Wikipedia

Tube End