This Science Behind Vacuum Electrical Connections: The Method These Operate

Vacuum electrical connections play a crucial role in a variety of research applications by enabling the conveyance of electronic signals or energy across a vacuum barrier. These components are necessary in settings where preserving a vacuum is imperative, such as in sealed chambers used for electron imaging, semiconductor manufacturing, and particle accelerators. Understanding the mechanisms and materials that constitute vacuum feedthroughs highlights their importance in contemporary technology and investigation.

At their core, sealed electrical feedthroughs consist of conductive materials that are carefully separated from the surrounding environment. This isolation is critical for avoiding any loss that could compromise the vacuum environment. Typically, these feedthroughs are engineered to resist high voltages and fluctuating temperatures, making them versatile for numerous applications. In this piece, we will delve into the science behind these components, including how they are constructed and the principles that govern their operation in sealed systems.

Principle of Operation

Vacuous electric feed-throughs function as crucial elements in upholding the validity of vacuum installations while enable electric currents and energy to pass through a barrier. They work by creating a hermetic connection between the outside world and an isolated vacuum chamber. This closure is crucial to stop atmospheric gases from infiltrating the vacuum space, which could endanger tests or devices sensitive to environmental conditions.

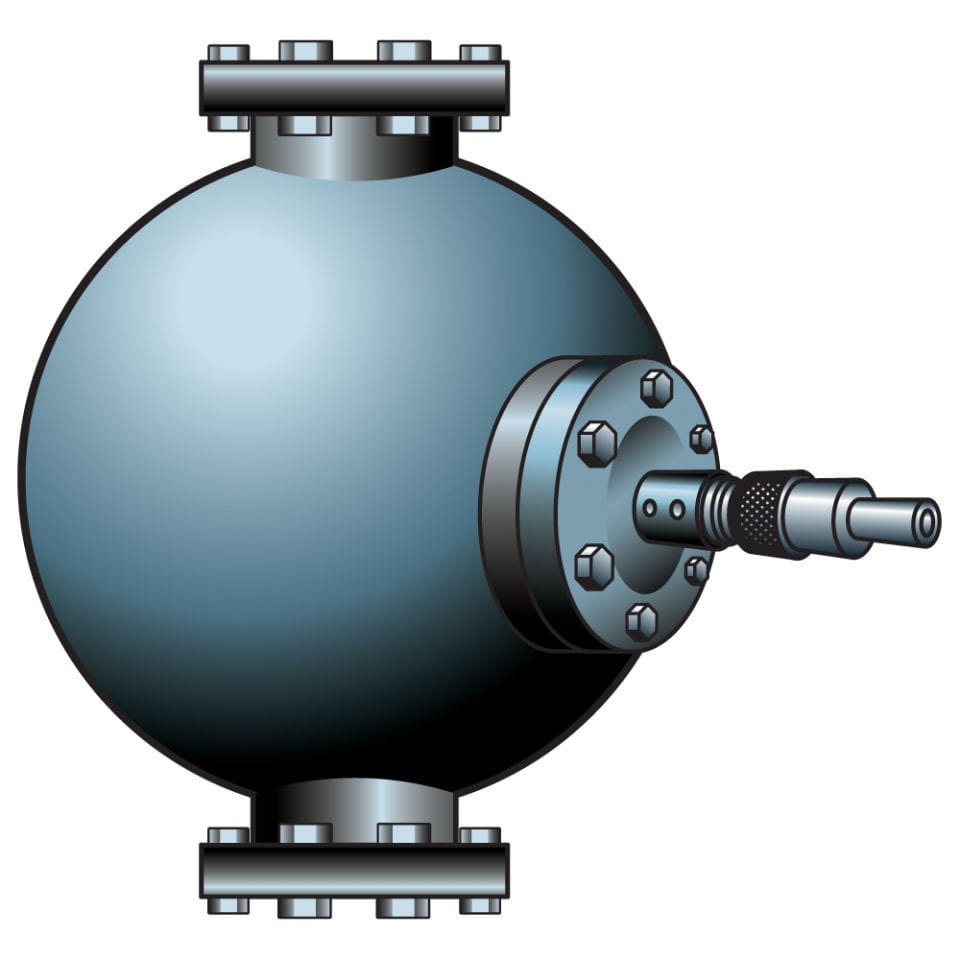

The basic design of a vacuum feed-through generally consists of conducting materials that are insulated from the vacuum environment. Ceramic insulators are commonly used because of their superior insulating properties and ability to withstand high temperatures and pressures. The conductive pathways might be metallic rods or wires that protrude through the feed-through and are sealed to the insulator, guaranteeing that electrical current can flow without risking the integrity of the vacuum seal.

Functioning is accomplished through careful design that balances electrical conductivity with vacuum stability. Depending on the use, feed-throughs can be engineered for varying voltage and current ratings. Additionally, developments in materials and production processes have led to the development of customized feedthroughs that can support high-frequency transmissions or specific thermal conditions, rendering them adaptable tools in research and industrial applications.

Key Components

The main component of vacuum electrical feedthroughs is the insulator, that is crucial for ensuring electrical isolation between the inside and outside of the vacuum environment. Typically made from materials like ceramic, this insulator must withstand high temperatures and vacuum conditions while preventing electrical current from leaking. This ability to maintain an effective electrical barrier is essential for the safety and functionality of the systems relying on these feedthroughs.

Another key element is the conductive element, that can vary in design depending on the application. Metallic pins or wires are common choices, allowing electrical signals or power to pass through the vacuum barrier. The choice of material selection for these conductive components is vital, as it needs to be compatible with the insulator and capable of enduring the specific environmental conditions without degrading.

Lastly, the sealing mechanism plays a critical role in maintaining the integrity of the vacuum. Typically created using premium metal-to-ceramic seals or glass seals, this component ensures that no gas or particles can enter the vacuum chamber. The seal must be designed to withstand thermal expansion and contraction while maintaining a robust barrier, integral to the reliability of vacuum feedthroughs in multiple applications.

Applications and Benefits

Electrical feedthroughs are vital parts in numerous technological industries, especially in sealed systems employed for study and fabrication. They allow the seamless transfer of power currents and energy into sealed chambers without sacrificing the integrity of the seal. Uses range from research experiments in particle physics and microchip fabrication to industrial processes such as surface finishing and substance testing. Their ability to withstand severe environmental conditions makes them invaluable in these fields.

One of the key advantages of employing sealed feedthroughs is their capacity to maintain a consistent sealed environment. This is crucial for guaranteeing accurate experimental results and premium product outputs. By offering consistent electrical connections while stopping gas escapes, these connections enhance considerably to the overall effectiveness and performance of sealed environments. Their configuration minimizes issues like contamination, which can adversely influence sensitive processes.

Furthermore, vacuum connections improve system reliability by offering sturdy and long-lasting connections. Many models include strong materials that can withstand severe environments, including elevated temperatures and corrosive conditions. This longevity minimizes the need for frequent maintenance and replacements, eventually lowering running costs and increasing productivity. Thus, incorporating vacuum feedthroughs into systems not only improves efficiency but also promotes sustainable methods in high-tech industries.