The key benefits of Using a Soldering Robot

There are many benefits to making use of a soldering robotic. It increases rate and production, needs no annual abandon, breaks, or attention strain, and could operate around typically the clock. It furthermore is far simpler to train a new robot operator when compared to the way it is a manual solderer. A single operator can supervise multiple robot stations. They also can be programmed quickly. Keep reading to learn even more about soldering automated programs. And don't forget to check out the many benefits that they can provide for your current business.

Cartesian soldering robots offer sophisticated accuracy

The make use of of soldering robots improves speed and even accuracy. They are easier to train as compared to manual solderers, no longer need annual abandon, and can function round-the-clock. Additionally, soldering robots offer higher throughput. Some associated with the best soldering robots have pré-réglable features, which permit the operators to be able to fine-tune the automatic process as necessary.

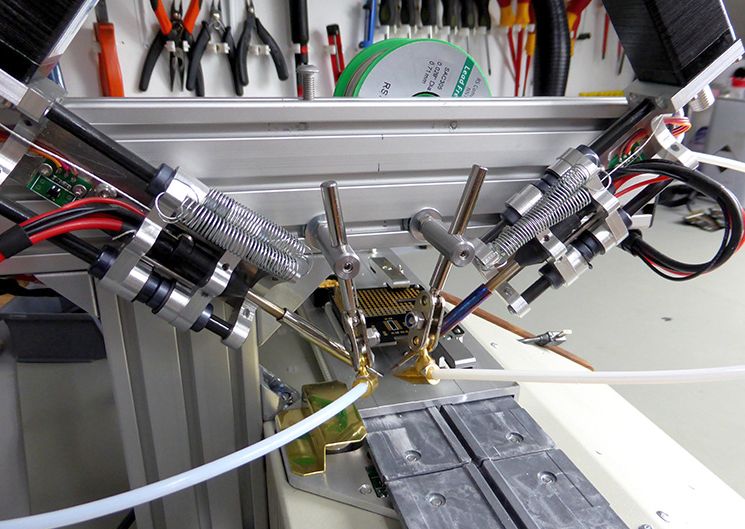

Since a high-end program, precision is important. Cartesian soldering software require highly-precision mechanised components, such as ball-rail tables and ball-screw actuators. High-precision linear bearings minimize deflection of the forearms and enable correct positioning. Cartesian programs can scale by bench top setups to large manufacturing applications. robotic soldering machine soldering robots offer high end accuracy, but are unsuccessful in more complex applications.

As a new result, cartesian automated programs are a little bit more hard to manage than other automatic robot types. Additionally, technicians may be fewer comfortable with managing multiple axes and even cables, but brand-new high-speed communication systems can help along with this challenge. Moreover, technical engineers should never base results about the performance involving a robot on just one aspect. Cartesian soldering automated programs also offer versatility for engineers.

These people can be scaled up for greater programs

The work with of industrial robots is increasing manufacturing efficiency, particularly intended for soldering. Whether a person are looking with regard to an one-person solution or an computerized solution, TM Robotics offers a number of developing automation equipment to be able to meet your requirements. Like a founding partner of ELMOTEC, a new Swiss family-owned firm, we are able to provide a person with a comprehensive listing of options.

Cartesian robotic arms will be an excellent alternative for bench-top programs. They balance speed and precision while being compact in addition to lightweight. But, if you need dexterous movements, the SCARA robot will fall short. Nevertheless, the accuracy and even speed of SCARA robots is enough for most soldering programs. These robots can be scaled upwards for larger software, including more complicated and intricate soldering applications.

Soldering robots improve speed, persistence, and accuracy regarding soldering joints. Automatic soldering robots use the equivalent solder, for a certain period of moment, and use consistent heat, to ensure that parts are of the identical high quality every time. Robotisation eliminates the likelihood of Monday Morning hours solder joints. It also provides a higher level00 repeatability and accuracy than an individual operator.

They usually are faster than human being soldering

Robotic soldering machines can handle concluding the same process more quickly compared to a human operator. Because soldering programs do not have human fatigue, they will are effective at spending as much moment as necessary in each solder joint. Also, unlike humans, soldering robots are usually more accurate. This is because robots use servo motors that can easily move them to sub-millimeter precision, permitting for greater repeatability and less problem.

Depending on the board and even components being soldered, the soldering approach can be divided straight into two types. Trend soldering is a more complex method of soldering, involving careful monitoring of both the board temperature in addition to the time in a solder wave. If improperly carried out, this procedure can result in board defects. Even so, wave soldering is usually a highly powerful approach to soldering with regard to many applications.

That they can be programmed quickly

With simple programming software, soldering robots can end up being programmed to perform the particular same task once again. You can manage the soldering points and length regarding the process. If you want to stop typically the soldering process, a person can simply replace the tip timing make it. There will be no need to employ specialized personnel in order to program these automated programs. It is a simple process, which often eliminates three options of error.

Besides its easy programming, soldering robots are capable of producing parts quicker than a human being. These robots no longer are afflicted by fatigue, and spend only as much time upon each solder mutual as is necessary. It will help them achieve better repeatability as compared to humans do. Found in addition, soldering software are designed along with servo motors intended for sub-millimeter accuracy. This particular ensures more steady production and fewer errors.