The Undeniable Gains of Personalized Injection Shaping for Enterprises

In today's competitive marketplace, companies are constantly searching for innovative ways to improve productivity, lower expenses, and raise product quality. One solution that has gained substantial traction in recent years is tailored injection molding. This production process allows businesses to produce highly precise and tailored plastic components, making it a worthwhile option for sectors ranging from automotive to retail goods.

The advantages of bespoke injection molding go beyond mere production capabilities. By utilizing this technology, businesses can achieve increased design flexibility, minimize material waste, and significantly shorten lead times. Whether you are a startup looking to create your first product or a established manufacturer looking to improve your production line, tailored injection molding offers clear benefits that can elevate your operations and deliver superior results.

Financial Efficiency and Scalability

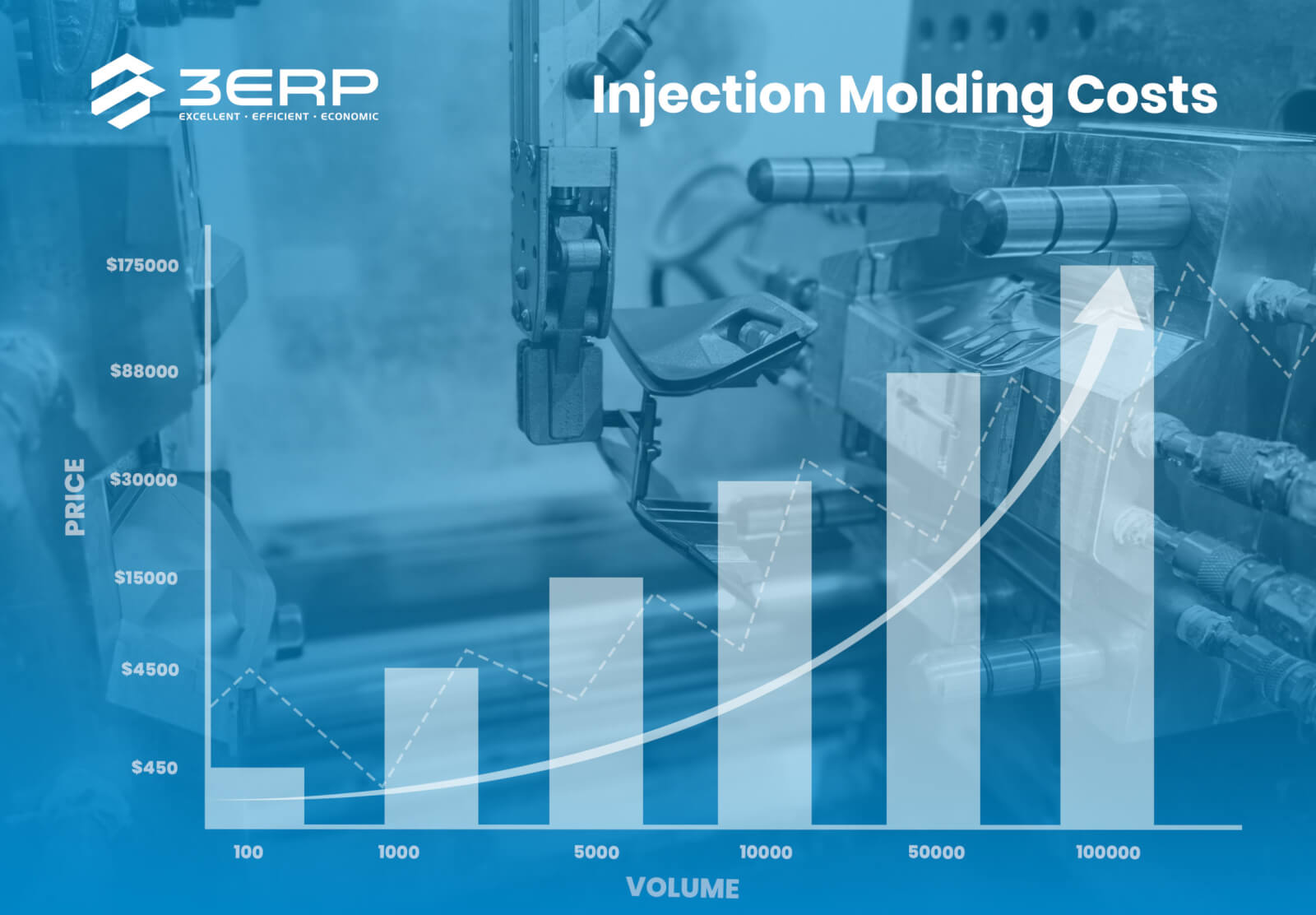

Bespoke injection molding is very economical, particularly for enterprises looking to manufacture massive amounts of goods. The initial setup may require a significant expense in formers and machinery, but the individual product cost drops significantly as production scales up. Once the mold is created, it can be used to manufacture thousands or even millions of identical parts, dividing the development and initial costs over a broader scope of products. This allows companies to achieve economies of scale that are difficult to duplicated with other manufacturing processes.

One more key advantage of tailored injection molding is the adaptability it offers in terms of output capacity. Whether a enterprise needs a minor quantity for a targeted purpose or aims to boost production for vast audience delivery, tailored injection molding can easily accommodate these different requirements. Adjustments can be made to the output cycle without significant hold-ups or further expenditures, enabling companies to respond swiftly to market demands and changing customer preferences.

In addition, bespoke injection molding supports rapid prototyping and development. Companies can create prototypes efficiently and efficiently, allowing for design iterations and upgrades before full-scale production begins. This responsiveness not only reduces time needed to launch but also minimizes the risk of expensive errors, making it easier for businesses to develop and improve their offerings. The ability to adjust output levels while maintaining quality standards makes bespoke injection molding an indispensable tool for companies seeking to improve their production techniques.

Improved Item Excellence

Custom injection molding allows for precise control over the fabrication process, resulting in higher product quality. This approach enables manufacturers to create parts with tight tolerances and consistent dimensions, which is critical for certifying the functionality and reliability of the final products. In contrast to traditional manufacturing methods, injection molding can duplicate complex designs and complex geometries with outstanding accuracy, lowering the likelihood of defects.

Additionally, the substances used in custom injection molding can be meticulously chosen to meet the performance requirements of a product. This implies that businesses can select superior thermoplastics or thermosetting polymers that boost durability and performance. The capacity to customize materials to suit particular applications ensures that products not only meet but often outperform the expectations of end-users, culminating in increased customer satisfaction and fewer returns.

Moreover, the productivity of the custom injection molding process enhances overall product quality. With cutting-edge technology and automation in modern injection molding machines, the process decreases human errors and improves consistency. As a result, products are crafted faster and with less flaws, allowing businesses to maintain high standards in quality control, consequently reinforcing their standing in the marketplace.

Versatility and Design Flexibility

Custom injection molding offers exceptional flexibility, enabling businesses to manufacture a variety of products customized to their specific needs. The process enables the use of various materials, including plastics, rubber, and metals, that can be molded into intricate shapes and sizes. This flexibility ensures that companies can produce items that meet specific requirements, catering to different industries from consumer goods to manufacturing applications.

In addition to material versatility, custom injection molding provides remarkable design flexibility. Designers can develop intricate and cutting-edge designs that can be difficult or hard to achieve with other manufacturing methods. The ability to create complex features such as undercuts, surface finishes, and varying wall thicknesses allows for enhanced aesthetics and performance in the final product. This level of customization can give businesses a competitive edge by enabling them to adapt quickly to market trends and demands.

Additionally, the speed of custom injection molding processes enhances design flexibility. With progress in technology and machinery, prototypes can be created quickly, allowing for fast revisions and modifications. This means businesses can refine their designs rapidly based on feedback or testing, leading to enhanced product quality and customer satisfaction. The combination of versatility and design flexibility makes custom injection molding an invaluable resource for businesses seeking to innovate and thrive in the current ever-changing marketplace.