The Ultimate Guide to Freeze Drying Equipment: Preserving Perfection

In a global increasingly focused on sustainability, nutrition, and long-term food storage, unique process has emerged through the realms of laboratory science and astronaut meals to the mainstream. At the heart of this revolutionary preservation method lies a sophisticated piece of technology: the freeze dryer. But what is this equipment, and how does it transform fresh, perishable items into lightweight, shelf-stable treasures?

This article delves in the world of freeze drying equipments, exploring its core components, the way it operates, along with the different types intended for everything from home kitchens to industrial production.

What is Freeze Drying? A Quick Primer

Before understanding the equipment, it's important to grasp the procedure. Freeze drying, scientifically referred to as lyophilization, is a dehydration method that works by freezing something and then lowering the surrounding pressure to allow the frozen water within the material to transition straight from a solid with a gas (an operation called sublimation).

The result? A product that retains its original shape, color, nutrients and vitamins, and flavor almost perfectly, with 98-99% of its moisture removed. Simply add water, and it rehydrates to a state remarkably all-around its fresh form.

The Core Components of a Freeze Dryer

While designs vary by size and sophistication, all freeze dryers share four fundamental components that work in concert to try and do the lyophilization process.

1. The Chamber

This may be the "workspace" of the freeze dryer in which the product is placed. It's a robust, vacuum-tight enclosure, often made from stainless steel, built to withstand significant pressure differences. Inside, you will discover shelves, which in advanced models are temperature-controlled. The chamber's door has a strong seal, similar to an industrial-grade pressure cooker, to keep up the critical vacuum.

2. The Freezing System

Sublimation is only able to occur when the product's water is thoroughly frozen. The freeze dryer achieves this in a of two ways:

Shelf Refrigeration: The most common method, in which the shelves can be cooled, often to temperatures just -40° to -50°C (-40° to -58°F). This conducts cold directly to the product trays.

External Freezer: Some systems require a separate, pre-freezing step where the product is frozen in the standard freezer before being loaded to the chamber.

3. The Vacuum Pump

This will be the engine from the entire operation. Once the product is frozen, the vacuum pump dramatically lowers mid-air pressure inside chamber. This pressure drop is exactly what enables the frozen ice crystals to sublimate, bypassing the liquid phase entirely. Without a robust and reliable vacuum pump, the method simply wouldn't work.

4. The Condenser

As water vapor sublimes through the product, it must be captured and re-frozen; otherwise, it would simply re-condense elsewhere. The condenser is definitely a cold coil (even colder as opposed to product shelves, typically -60°C or below) that provides a "cold trap." The water vapor travels through the chamber towards the condenser, where it instantly re-freezes as ice. This protects the vacuum pump from moisture and completes the dehydration process. At the end in the cycle, this ice can burn during a defrost phase.

How the Equipment Works: A Step-by-Step Process

Loading & Freezing: The prepared strategy is spread onto trays and loaded in the chamber. The freeze dryer's freezing system rapidly lowers the temperature, solidifying the lake content.

Vacuum Activation: The vacuum pump is engaged, sucking air out of the chamber to generate a near-perfect vacuum.

Primary Drying (Sublimation): With the vacuum established, the shelf temperatures are slightly raised, providing adequate energy for the frozen water to sublimate. This will be the longest phase of the cycle, often taking much time or even days, depending on the product's thickness and water content. The water vapor flows on the condenser and turns time for ice.

Secondary Drying (Desorption): After most with the free water has disappeared, handful of bound moisture remains. In this final phase, the shelf temperature is increased further (though still well below room temperature) to destroy the molecular bonds and remove this residual water, ensuring maximum shelf-life.

Completion & Unloading: The vacuum is slowly released, the chamber is opened, as well as the perfectly preserved, freeze-dried method is removed, ready for packaging.

Types of Freeze Drying Equipment

Freeze dryers usually are not one-size-fits-all. They are categorized based on their scale and application.

Laboratory Scale: Used for research, pharmaceuticals, and biotechnology. These units prioritize precision, data logging, along with the ability to process small, sensitive samples. They often feature sophisticated programmable controls and are built for repeatability.

Pilot Scale: A middle-ground option used for process development and small-batch production. Companies have used them to scale up a recipe through the lab to full production without wasting resources.

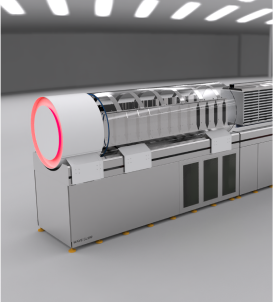

Industrial Scale: These are the giants with the industry. Used for large-scale food production, pharmaceutical manufacturing, and preservation of historical artifacts. They feature massive chambers, automated loading/unloading systems, and therefore are designed for continuous, high-volume output.

Home/Consumer Grade: A growing rapidly market, these compact units bring exclusive onsite process to the household. Brands like Harvest Right have popularized this category, allowing families to preserve garden harvests, create emergency food supplies, making lightweight snacks for camping and hiking.

Key Considerations When Choosing Equipment

Whether to get a business or a home, choosing the right freeze dryer involves several factors:

Capacity: Measured from the tray area or volume. How much do you need to process per batch?

Shelf Temperature Range: A wider range offers more versatility many different products.

Condenser Capacity: Determines how much moisture the system can remove before needing to defrost.

Pump Quality: The vacuum pump is very important for performance and longevity. Oil-based pumps are powerful but require maintenance; oil-free pumps are cleaner but tend to be less robust.

Ease of Use & Control: From simple buttons to full-color touchscreens with pre-programmed cycles.

Conclusion: More Than Just a Machine

Freeze drying equipment can be a gateway to a new a higher level preservation. It’s a technology that locks in summer's berry harvest to get a winter smoothie, ensures a life-saving vaccine remains stable across the globe, and allows an explorer to carry a gourmet meal of their backpack. By comprehending the intricate dance between its chamber, freezer, vacuum pump, and condenser, we could appreciate this remarkable equipment not just as an appliance, but as being a tool for developing a more resilient, efficient, and flavorful future.