The Reasons Why Injection Molding Technology represents the Next Frontier in Manufacturing

In today's quickly changing manufacturing landscape, the search for productivity, accuracy, and affordability is crucial. As businesses strive to meet growing demands and quicker production times, the injection molding process has become a top technology that aims to transform the way items are created. This flexible process is not just about molding materials; it represents a significant shift towards more sustainable and innovative manufacturing practices.

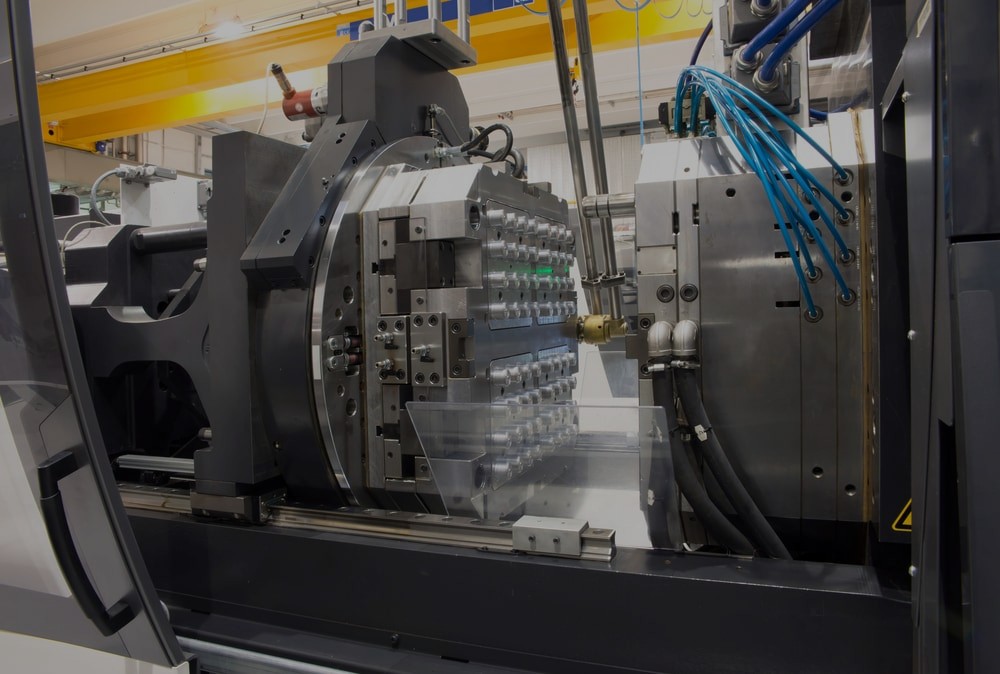

Injection molding services offer a host of advantages that make them attractive to companies of all sizes. From creating complex geometries with remarkable accuracy to enabling the use of a multitude of materials, this technique is notable in its ability to streamline production while maintaining high quality. As we explore the benefits of injection molding, it becomes clear why this method is ready to play a vital role in the upcoming of manufacturing.

Advantages of Injection Molding

One of the benefits of injection molding is its efficiency in producing large quantities of parts. This manufacturing process allows for quick production times, making it ideal for businesses seeking to scale up their operations. Once the mold is created, parts can be produced in a few seconds, significantly reducing the duration from concept to market for new products. This efficiency not only enhances productivity but also lowers labor costs associated with manufacturing.

A further advantage of injection molding is the precision and consistency it offers. The process enables the creation of complex shapes and intricate designs with high tolerance levels. This level of detail is difficult to achieve with alternative manufacturing methods. Additionally, the stability of the injection molding process means that part quality remains uniform batch after batch, which is essential for maintaining brand reputation and meeting customer expectations.

Economic viability is also a key factor that makes injection molding a preferred choice among manufacturers. Although the initial investment in mold creation can be high, the sustained savings in production costs make it economically viable for large-scale production. The materials used in injection molding are often less expensive than alternatives, and the ability to reuse scrap materials further enhances cost savings. Businesses opting for injection molding services can benefit from these reductions and still ensuring the quality and durability of the products.

Uses of Injection Forming in Multiple Industries

Injection molding is widely used throughout many industries due to its flexibility and effectiveness. One notable application is in the automotive sector. Manufacturers utilize injectable molding to create complex parts such as control panels, fenders, and inside components. The process allows for the production of light yet strong parts that meet rigorous safety and performance requirements. The ability to produce high volumes of reliable quality components makes injection molding essential for meeting the requirements of current automotive production.

Another key industry that benefits from injection forming is consumer electronics. Gadgets such as mobile devices, slates, and technology that can be worn rely on injection-molded parts for their enclosures, controls, and inside structures. The exact and intricate designs made achievable through injection molding allow for innovative product design while maintaining a high level of aesthetics and performance. As technology continues to evolve, injection molding plays a crucial role in enabling fast prototyping and mass production of new electronic gadgets.

In the medical field, injection forming is essential for producing various tools and equipment, including needles, surgical instruments, and enclosures for digital medical tools. The technique not only enables the production of high-precision, sanitary components but also supports the development of tailored solutions for medical practitioners. With the growing need for advanced medical devices, injection molding services are essential for ensuring that products are created to the utmost standards of quality and industry regulations.

Emerging Trends in Injection Molding Technology

As the requirement for precision and effectiveness in production expands, injection molding technology keeps on to evolve. One significant trend is the incorporation of advanced materials, including bio-based and repurposed plastics, which cater to the growing focus on eco-friendliness. Manufacturers are examining innovative materials that not only meet operational standards but also minimize ecological impact. This shift towards greener materials is expected to transform product design and production processes in the immediate future.

Another significant development includes the adoption of automation and Industry 4.0 technologies in injection molding services. Intelligent factories equipped with Internet of Things technology allow immediate monitoring and data collection, enhancing productivity and reducing idle times. Automated systems, such as automated arms for part handling and quality control, simplify manufacturing processes and enhance precision, allowing that producers can deliver high-quality components at a quicker pace.

Lastly, the rise of 3D additive manufacturing and additive manufacturing is impacting conventional injection molding methods. While injection molding remains the dominant method for large-scale production, the ability to quickly create prototypes using 3D fabrication allows companies to innovate designs and evaluate concepts more quickly. This combination of methods is paving the way for blended manufacturing strategies, where injection molding is utilized in conjunction with additive manufacturing to enhance adaptability and personalization in design and development.