The Reason Why Quality Control is Vital in Injection Molding.

In the world of manufacturing, the caliber of the end product can significantly impact a company's reputation and financial performance. This is especially valid in sectors that depend heavily on injection molding services. With the increasing demand for precision-engineered plastic parts, the importance of implementing strong quality control measures cannot be overstated. Making sure that each product satisfies stringent quality standards is essential not only for client contentment but also for preserving efficiency and minimizing waste in the manufacturing process.

Quality assurance in plastic injection molding service s is a multifaceted approach that encompasses multiple stages of production, from choosing materials to ultimate evaluations. By prioritizing quality at every stage, manufacturers can avoid defects, minimize redoing work, and cultivate a environment of excellence. As competition escalates in the industry, investing in quality assurance becomes a strategic advantage, allowing companies to provide reliable products while improving their credibility with clients.

Understanding QA in Plastic Injection Molding

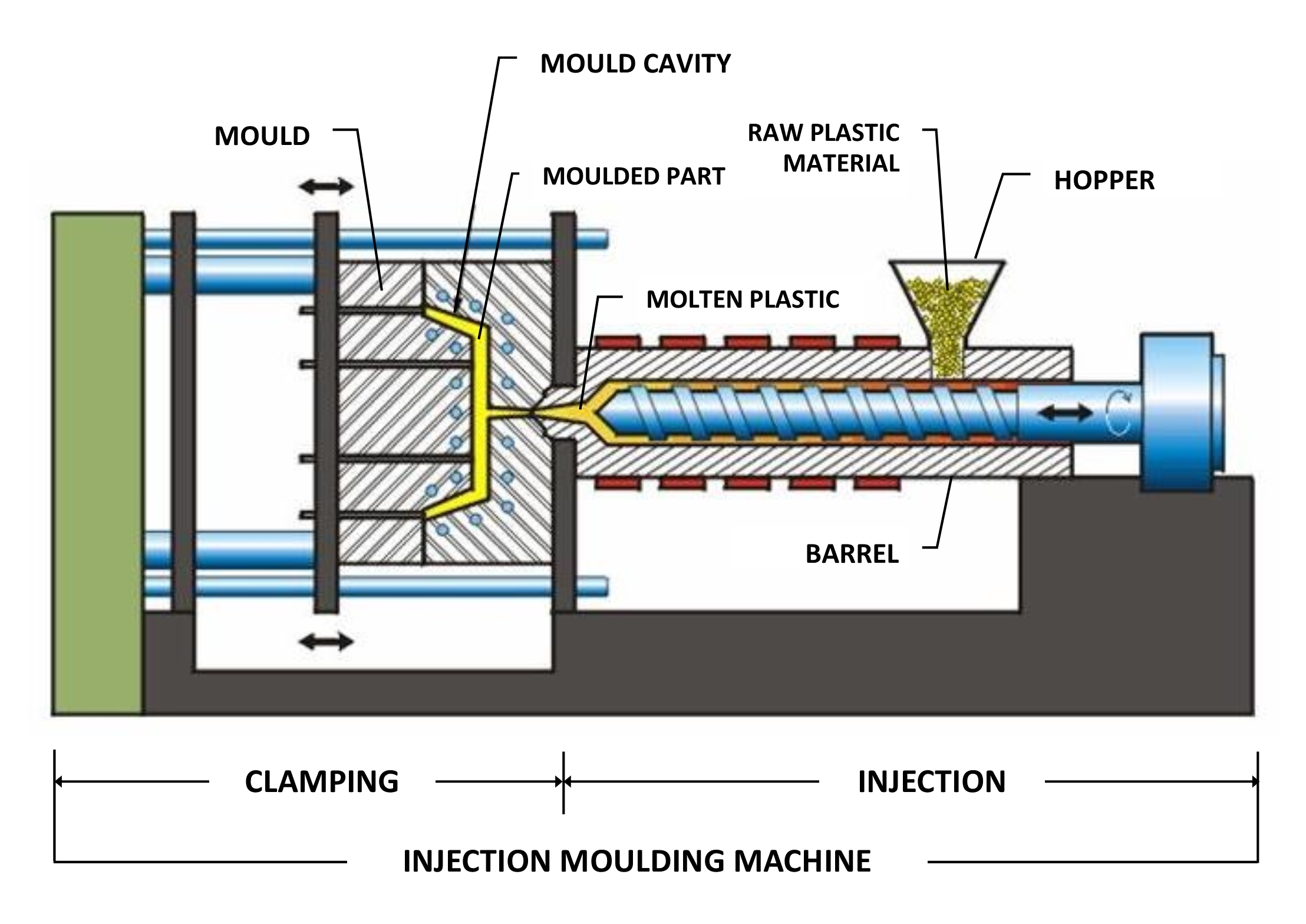

QA in injection molding refers to a systematic methods and procedures that verify products meet specific standards and customer demands. This involves a blend of thorough testing, inspection, and monitoring throughout the production cycle. By establishing a strong quality assurance framework, manufacturers can detect defects at an early stage, reduce waste, and enhance the overall efficiency of their plastic injection molding process.

The role of quality assurance in this field is complex. It includes everything from material selection and machine calibration to final product inspection. Each phase of the injection molding process is critical, as even slight deviations can lead to significant defects in the finished product. Complying with quality assurance protocols merely improves product reliability but also strengthens the firm's reputation in the challenging market of plastic manufacturing.

Additionally, quality assurance aids in maintaining compliance with industry regulations and standards. This is especially crucial in sectors where safety and performance are of utmost importance, such as automotive and medical. By focusing on quality, businesses that provide plastic injection molding services can show their commitment to excellence, potentially boosting customer satisfaction and loyalty while reducing costly recalls or rework.

Influences of Excellence on Product Efficiency

The quality of plastic injection molding processes plays a key role in shaping the total performance of the final product. High-quality molds and materials ensure that the parts manufactured meet the required specifications and functional requirements. When quality is prioritized, the end result is more likely to exhibit superior strength, durability, and tolerance to wear and tear, which are crucial for products used in challenging applications.

Inconsistent quality can lead to flaws such as warping, incomplete fills, or surface imperfections, which immediately impact the product's performance. For instance, a badly formed component may not interact properly with other parts, leading to integration problems or performance failures. By adhering to stringent quality assurance measures during the molding procedure, manufacturers can significantly reduce the chance of these issues, producing reliable products.

Moreover, the standing of a brand is often connected to the quality of its products. When customers receive high-quality items that perform as anticipated, it builds trust and loyalty. Conversely, quality issues can lead to increased returns, warranty claims, and negative reviews, ultimately damaging the brand's image. Thus, ensuring exceptional quality in plastic injection molding service is not only vital for product performance but also for maintaining customer satisfaction and a solid market position.

Top Strategies for Ensuring Excellence in Injection Molding

To achieve superior outcomes in plastic molding, it is crucial to emphasize exactness in the design phase. Efficient collaboration between design engineers and developers can lead in an improved mold design that minimizes issues and guarantees proper function. Employing advanced CAD applications and modeling tools can help identify possible problems before production begins, thereby reducing expensive failures and boosting overall standards.

Consistent care and calibration of molding machinery are critical to sustaining quality throughout the production cycle. Equipment should go through scheduled checks and tweaks to prevent variations in performance. Establishing a thorough maintenance schedule helps in identifying degradation on machines, which could cause defects in the produced items. Ensuring machines in peak performance ensures that the required tolerances and quality finishes are consistently achieved.

Finally, instituting a strong quality management process is essential in ensuring high standards in plastic injection molding service. This involves systematically inspecting completed products against specified criteria and utilizing process control methods to oversee production. Educating workers on standards and employing modern measurement tools can boost the efficacy of these inspections. By developing a culture of excellence, companies can reliably deliver trustworthy products that meet or go beyond client requirements.