The Main Principles Of Popular Mechanics - Jan 1915 - Page 27 - Google Books Result

5 Easy Facts About Steel Shop Drawings - Both 2D & 3D Fabrication Drawings Explained

" Paper size is no longer a concern." The shop made a server file tree structure that mirrored the structure in Job, EMPLOYER, with separate folders for quote processing, order processing, shop flooring control, product control, labor reporting, shipping, and information collection. A store employee focuses to check out the illustration's details.

" When we began, the file tree structure was all over the location," Wagner stated. "As we began something new, we 'd include a new folder. But within the previous couple of months we've altered it to mirror the file structure in Task, BOSS. It took some time to move the digital data that we had already gotten in, however the effort was definitely worth it." 4.

Supervisors also gradually bought a dozen computer systems for the store flooring, enough for 2 employees to share each computer system workstation. Unlike the high-powered stations running 3D CAD in the workplace, computer systems on the store flooring didn't require to be high-end machines, which assisted minimize expenses. 5. Need More Info? out software application. Amtex's paperless effort didn't come entirely without software application investment.

Antelope County News - SHOP LOCAL & WIN! It's never been easier to win $100 to your local grocery storeJust get a bingo to be entered into our drawing How do Shop Drawings - Steel & Fabrication Shop Drawings Experts

Shop Drawings - Steel & Fabrication Shop Drawings ExpertsThe Greatest Guide To Scientific American - Volume 82 - Page 174 - Google Books Result

No longer were notes concealed within operators' personal note pads or, even worse, locked inside their heads. "This effectively assisted us share tribal knowledge," Wagner said. Regarding assessment records, Amtex's quality guarantee department uses Unipoint, an add-on for Task, MANAGER. "We can import the PDF illustration, and Unipoint will bubble it," Wagner said, discussing that "bubbles" indicate specific inspection points on the drawing and the appropriate tolerance.

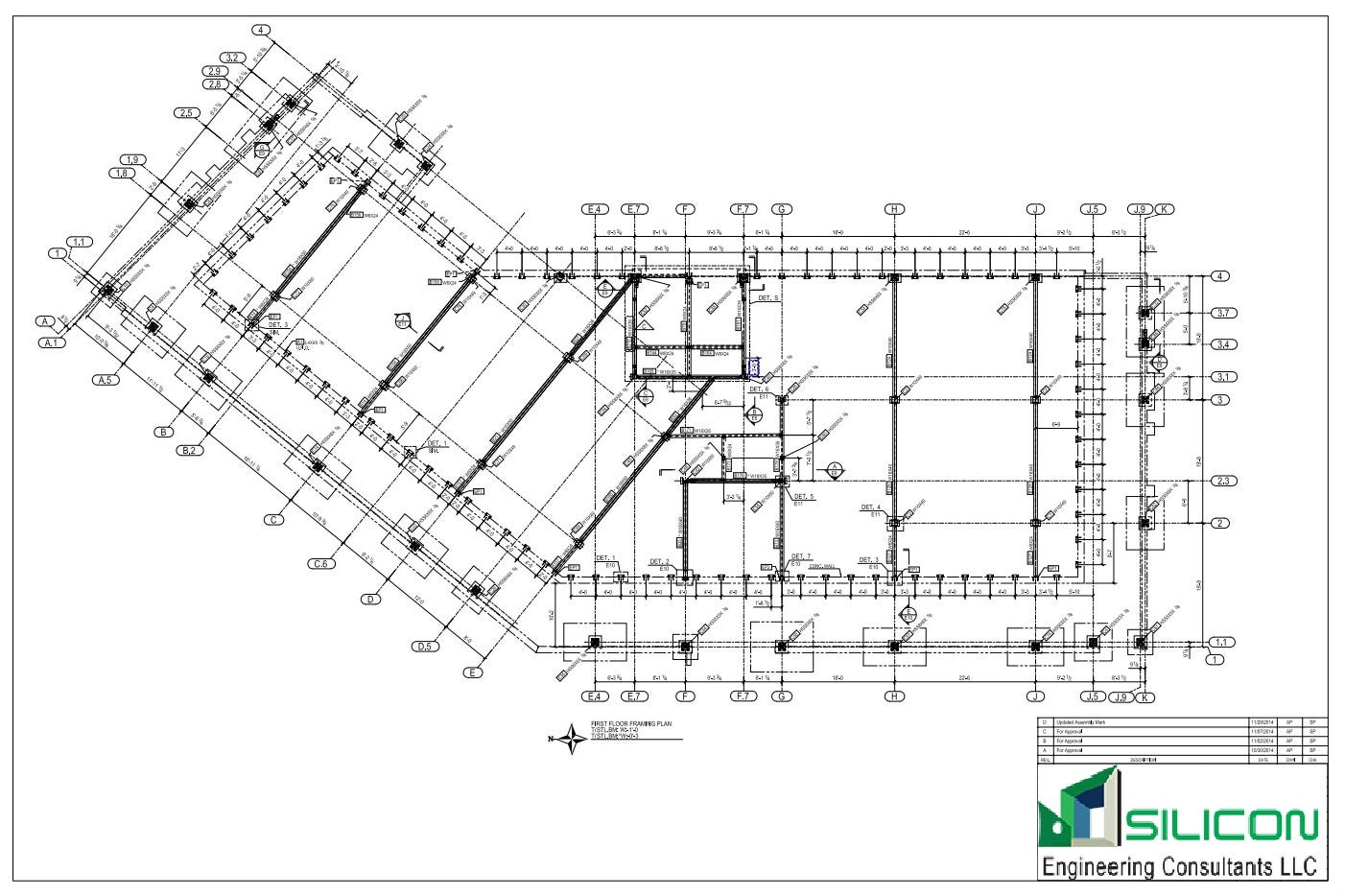

Outsourcing Structural Steel Fabrication Shop Drawings - Theparadigmengineering.com

Outsourcing Structural Steel Fabrication Shop Drawings - Theparadigmengineering.comThe laser operator needs to examine the product type, grade, and density, along with the length and width of the flat. Journalism brake operators examine to ensure proper orientation, especially for nonsymmetrical parts, and they determine every flange. Whatever additional examination requirements stay are managed by QA. Relocating to paperless here included more error-proofing.

In the worst case, an out-of-tolerance part slipped through to the next operation, which led to more lost effort, considering that QA would wind up rejecting the work in completion. Accessing the examination records digitally, operators who key in a measurement that runs out tolerance see an instant red highlight on the screen.