** The Function of PLM300 in Optimizing Plant Upkeep Methods **.<br>

Plant upkeep is a cornerstone of functional performance in industries depending on complex machinery and systems. Appropriate upkeep methods make sure very little downtime, reduced functional costs, and boosted safety. SAP's ** PLM300 ** program, focusing on plant maintenance, has actually emerged as an essential tool for specialists aiming to maximize these techniques.

### What is PLM300?

PLM300 is a specific training module in the SAP Plant Upkeep (PM) application. It supplies understandings right into planning, executing, and keeping an eye on upkeep tasks using SAP's incorporated platform. This course outfits individuals with the technical expertise and tactical frame of mind to carry out efficient upkeep remedies.

### Trick Functions of PLM300 in Plant Maintenance Optimization.

1. ** Comprehensive Maintenance Planning **.

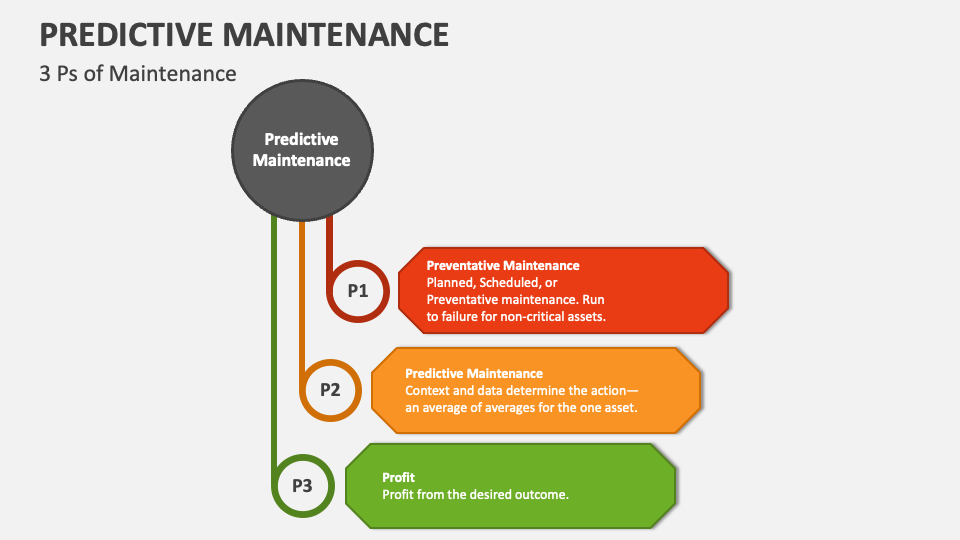

PLM300 highlights tactical planning by teaching users how to arrange, focus on, and allot resources successfully. With functions like precautionary upkeep preparation, companies can prepare for potential devices failings before they happen.

2. ** Integration with Service Processes **.

SAP PM incorporates seamlessly with various other SAP modules such as Materials Management (MM) and Manufacturing Planning (PP), making it possible for a holistic view of procedures. PLM300 shows exactly how this assimilation enhances process performance and decision-making.

3. ** Data-Driven Insights **.

By leveraging SAP's robust analytics, PLM300 participants find out to track tools efficiency, analyze failure trends, and make data-driven decisions. This ability is important in transitioning from reactive to anticipating maintenance techniques.

4. ** Streamlined Work Order Management **.

The training course provides hands-on experience in taking care of work orders, from development to conclusion. This ensures that upkeep groups operate effectively, reducing hold-ups and minimizing disturbances.

5. ** Improved Reporting and Compliance **.

PLM300 trains users to generate detailed records and guarantee conformity with market standards and regulations. This fosters openness and liability within upkeep procedures.

### Benefits of PLM300 Training.

### That Should Take Into Consideration PLM300 Training?

The program is excellent for:.

- Upkeep organizers and supervisors.

- SAP PM experts.

- Plant engineers and technicians.

- Workflow supervisors intending to incorporate SAP into maintenance techniques.

### Conclusion.

PLM300 functions as a crucial source in maximizing plant upkeep approaches. By taking on the principles and devices educated in this course, organizations can attain unrivaled effectiveness, integrity, and sustainability in their operations. If PLM300 – Business Processes in Plant Maintenance training course online aiming to revolutionize your upkeep approaches, buying PLM300 training is an action in the right instructions.

** Unlock the possibility of SAP PM with PLM300 and lead your plant maintenance techniques to success! **.