The Definitive Guide for Precast-concrete Details - SlideShare

Everything about CMHC's Best Practice Guide – Architectural Precast Concrete

Acoustics A precast concrete wall system and cast-in-place facade will provide similar performance relating to sound transmission from the outside to the interior of the building. Nevertheless, distressed and open joints between panels can offer a condition in which sound transmission to the interior may be increased. Material/Finish Toughness Precast concrete panels utilized in wall systems have several surfaces and shapes.

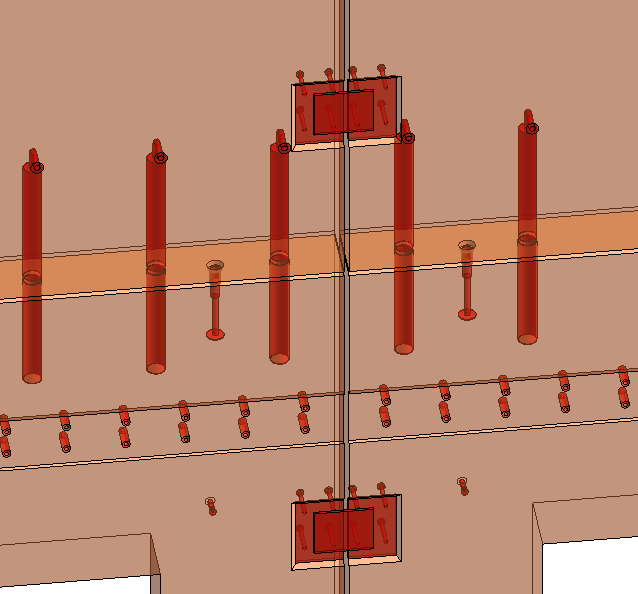

Auto-Inserting Connection Elements for Precast Concrete in Revit [WEBINAR] – BIM Software & Autodesk Revit Apps T4R (Tools for Revit)

Auto-Inserting Connection Elements for Precast Concrete in Revit [WEBINAR] – BIM Software & Autodesk Revit Apps T4R (Tools for Revit)Each of these surfaces presents a different challenge in producing a long lasting precast concrete panel. Sandblasting a concrete surface area can produce a surface that is less resistant to moisture penetration. As an outcome, a surface area treatment, such as a sealant, ought to be thought about where this method is used for ending up.

More complicated profiles in the surface of the panel typically need more workability in the concrete mix, much better consolidation strategies, and typically more post-production surface area repair work. Precast panels with varying depths of surface area profiling also require more care in maintaining sufficient concrete cover over the embedded strengthening steel. In summary, the more complex the look of a precast concrete panel, the more challenging and essential the review and approval process and quality assurance program.

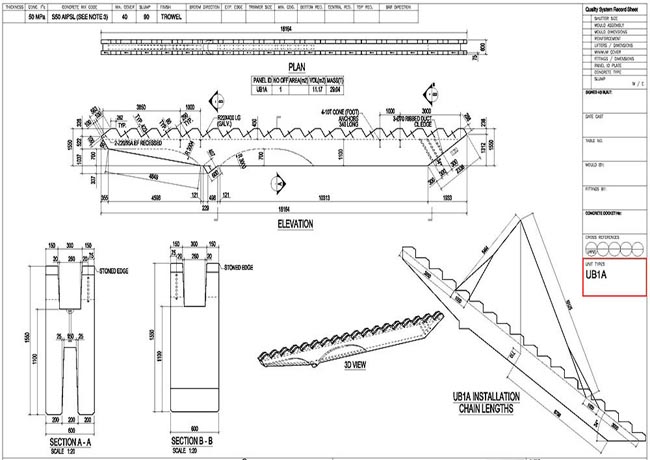

Precast Wall To Wall Connection - MOMENT Loop Box

Precast Wall To Wall Connection - MOMENT Loop BoxThe Best Strategy To Use For High Performing Precast Concrete Building Enclosures

Panel breaking, displacements, or other distress conditions can occur at areas where anchors are improperly or incorrectly linked. Poor building and construction is typically the outcome of bad quality control and out of tolerance fabrication or erection of the panels. Likewise, Solution Can Be Seen Here from dealing with during building and construction can result in panel splitting, some of which might not end up being obvious for numerous years.

Typically requirements are defined (air entrainment, maximum absorption, minimum compressive strength, and so on) to boost the sturdiness of the concrete. History of the concrete mix and finish can also supply beneficial details. ACI 318 defines different criteria for acceptance of a concrete mix. In addition, water-to-cement ratio, minimum compressive strength, air entrainment range and other requirements are likewise noted.

In addition to a precast concrete mix satisfying the requirements and suggestions of ACI 318, assessment and study of the historical performance of a specific concrete mix in a similar outside environment can also be carried out. Petrographic examination (ASTM C856) is likewise frequently utilized to evaluate aggregate in an effort to recognize the mineral composition of the concrete and especially the aggregate, and based upon these observations and previous knowledge of those attributes, to predict future efficiency.