The Buzz on KRMX01BookDL.pdf - Squarespace

DIY Smart Saw Review - The Power Tool Website Fundamentals Explained

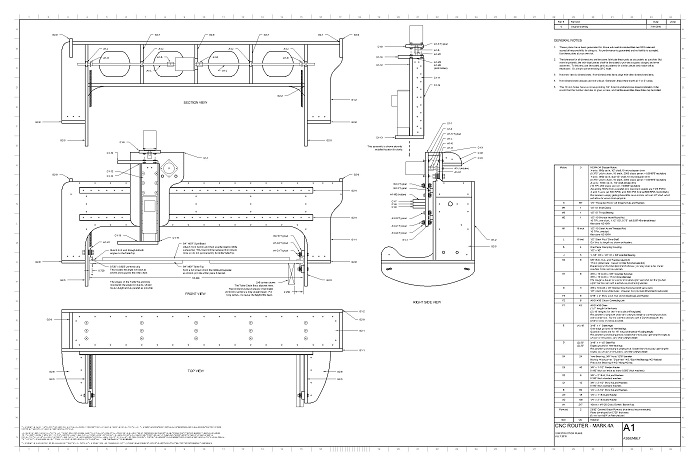

Depending on how numerous corners you cut with the DIY CNC Router, and how intricate your CNC Mill task is, a CNC Mill is most likely the most pricey, hardest to do, but many flexible DIY CNC Maker. While there have actually been some scratch-built CNC Milling makers done, you're finest off transforming a manual milling maker to CNC up until you have a lot of CNC experience under your belt.

There are a great deal of possibilities. Some to think about in order of heaviest/most pricey to lightest/cheapest consist of: Bridgeport-style Knee Mill: These are costly, and the heavy knee is not specifically well suited to CNC. OTOH, there are a lot of CNC 'd knee mills out there and absolutely nothing says, "Milling Maker" like a Bridgeport.

RF-45 and Clones: These are Chinese-made Bed Mills that are offered from all sorts of places and in all sorts of variations. They have a work envelope and rigidity comparable to a Bridgeport, but without the heavy knee, so they're much better suited to CNC tasks. Their most significant disadvantage is their spindle, which is limited to 1600 rpm.

8 Easy Facts About How-To_ Build your own CNC machine (Part 2).pdf - fileninja.net ExplainedGrizzly G0704: These mills are a little smaller than an RF-45, however they are a perfect CNC platform. Additional Info like Hoss at Hossmachine can offer full details of whatever you require to understand, plans, and frequently kits to assist with conversions. If the table and travels are big enough for your jobs, this will be a more affordable and much faster task than an RF-45.

IndyMill – DIY Open Source Metal CNC Machine – Indystry.cc

IndyMill – DIY Open Source Metal CNC Machine – Indystry.ccI do not think I 'd go any smaller than the X2, however you can do some amazing things with one as Hossmachine has demonstrated (complete automatic tool changer and VMC style enclosure). Here's a terrific post on choosing a donor maker for your DIY CNC Mill Job. An important note: Some newbies begin thinking of transforming a drill press to a milling device.

DIY CNC Router : 30 Steps - Instructables

DIY CNC Router : 30 Steps - InstructablesIt will need so much effort to produce an average outcome that it just isn't worth it. Here are some common machines: My Do It Yourself RF-45 Mill Conversion Hoss's G0704 CNC Conversion at a fairly early phase: he included a lot more!.

Examine This Report about Wei_Qin.pdf - IDEALS @ Illinoisno longer supports Internet Explorer. To search Academia. edu and the wider internet quicker and more securely, please take a few seconds to update your browser