The Best Strategy To Use For Xenosep SPE Starter Kit with Solvent Recovery, EPA Method 1664A - Hach USA - Overview

Solvent Recovery Units - Oil Sands Magazine

Solvent Recovery Units - Oil Sands Magazine ITAS Solvent recovery unit - Fives in Combustion

ITAS Solvent recovery unit - Fives in CombustionThe smart Trick of Organic Solvent Recovery Unit(RT200) - Yamato Scientific That Nobody is Discussing

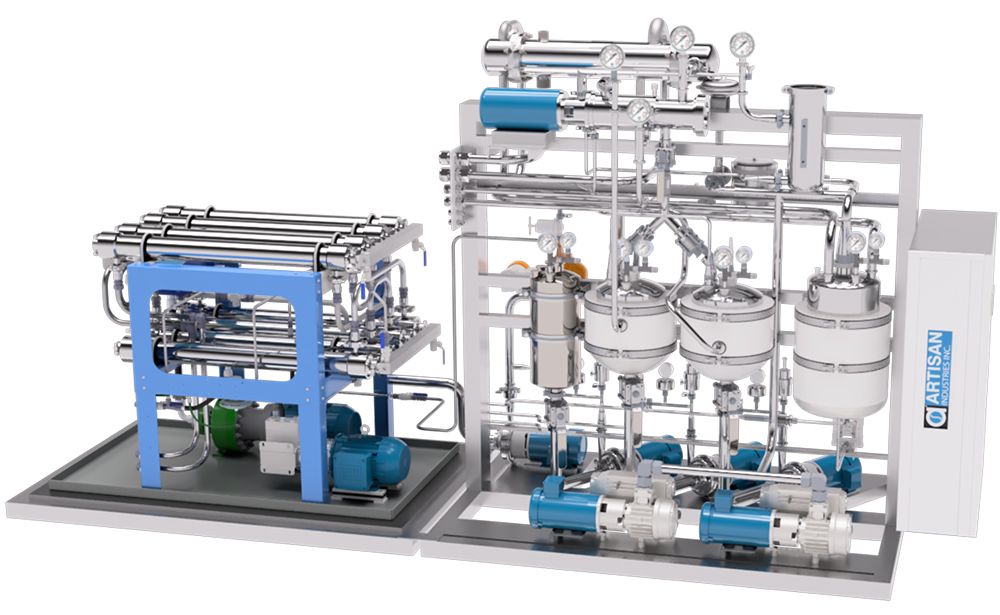

Our solvent healing systems are typically integrated into a total closed-loop solvent management system, making use of PRI's specialized and custom-designed Tidy and Dirty Solvent Tanks with feeds. In a closed-loop procedure, waste solvent is collected in a Dirty Solvent Tank, then piped to a Distillation System to separate the contaminants. Then, impurities are discarded and multiple-use solvent is automatically sent to a Clean Solvent Tank, which feeds your production process. PRI can engineer solvent management systems to support parts cleaning, paint lines or other producing procedures where solvents are utilized.

Adsorption procedures are helpful and flexible tools when it pertains to solvent healing as they can be applied with high performance at relatively low cost in cases in which the preferred part presents either a relatively small or a fairly high percentage of the stream. NexGen Enviro Systems Inc. adsorbents vary according to different functions. 108,109 Adsorbents with low polarity (activated carbon, etc.) tend to adsorb nonpolar substances, whereas ones with high polarity (e. g., silica, alumina) have greater affinity to adsorb polar substances. Nevertheless, some adsorbents operate via specific binding sites (e. g., molecular screens, molecularly imprinted polymers) rather than basic hydrophilic-hydrophobic interactions.

Solvent Recovery Plant - Dalal Engineering

Solvent Recovery Plant - Dalal EngineeringIn natural solvent recycling, the most regular concern is the removal of water material. Even traces of water can cause unanticipated solubility problems, side responses, or the decay of a reactant. There are different processes to recuperate damp solvents such as distillation approaches or fractional freezing, whereas adsorptive approaches are beneficial due to their low energy intake. Molecular sieves (with pore size 3 or 4 ), silica, and alumina are commonly used for solvent drying. 110,111 The polarity of the solvent impacts the efficiency of water elimination, which decreases with increasing polarity of the solvent. With the correct option of adsorption technique, residual water material in between 1 and 100 ppm is usually a sensible target.