The 6-Second Trick For SPEG-C_Plastic Screws - The Motion Control Components

Analysis of Energy Consumption in the Dry Drilling of PEEK GF30 - Scientific.Net

Analysis of Energy Consumption in the Dry Drilling of PEEK GF30 - Scientific.NetThe Basic Principles Of Sod - LKETRON® PEEK - Farnell

Besides, the worth of thrust force begins reducing when the drill advances from its cone length and in theory ends up being minimum when there is no contact of chisel and cutting edge with the workpiece once the drill reaches up to the plate's thickness ... This study analyzes 4 cutting conditions (dry, flood, Liquid CO2 (LCO2), and Liquid N2 (LN2)) based on energy intake and ecological impacts for drilling VT-20, a Titanium alloy.

The Life Process Assessment (LCA) analysis has actually been performed using Re, Ci, Pe 2016 midpoint (H) to identify the impact of cutting conditions on community, human health, and natural resources. Cryogenic environment with LN2 has actually been found as the most ecological cutting condition beside dry machining, while flood coolant has 94-99% of overall impact thinking about all cutting conditions ... For that reason, this work presents an index to define the sustainability in the machining, and in specific in the drilling, thinking about the expense, the energy, the time, the tool life and the roughness... In repercussion, the machining time is other impact aspect; it is conditioned by the cutting conditions (Saric et al., 2016) and the balance in between efficiency and sustainability must be found by an equilibrium in between machining energy and time intake through of the most affordable cutting forces (Alvarez et al., 2011) and the least expensive torques (Domingo et al., 2018b) because enable a most affordable energy (Domingo et al., 2013b), and finally this affects directly on the cost.

Lots of variables associate with the production processes, as the machining, and for this factor to know the contribution of these variables can add to get much better practices. Today work exposes an index of incorporated sustainability for the examination of the machining operations, in specific in the drilling. This index thinks about energy aspects of the procedure, as well as the surface area quality of the part and the life of the cutting tool, and enable the optimization through of an interaction algorithm, based upon the procedure cut-off specifications.

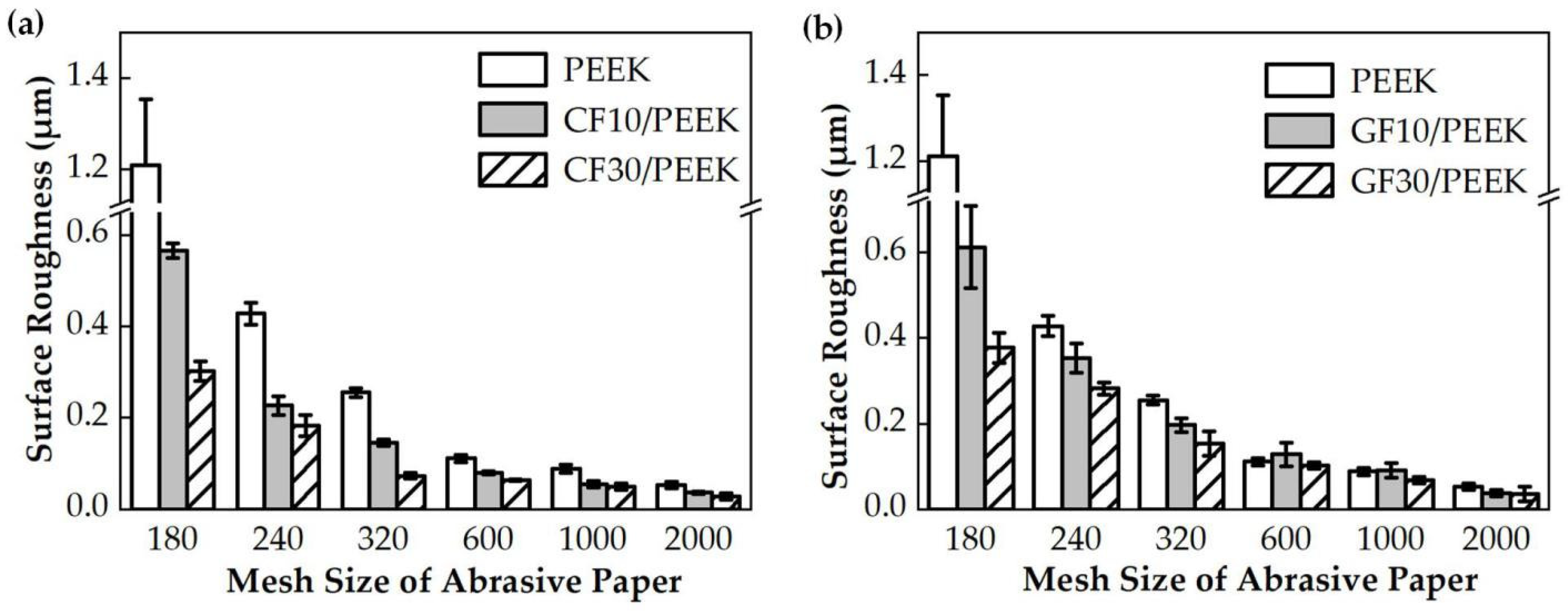

Mechanical and thermal properties of PEEK and PEEK GF30 - Download Table

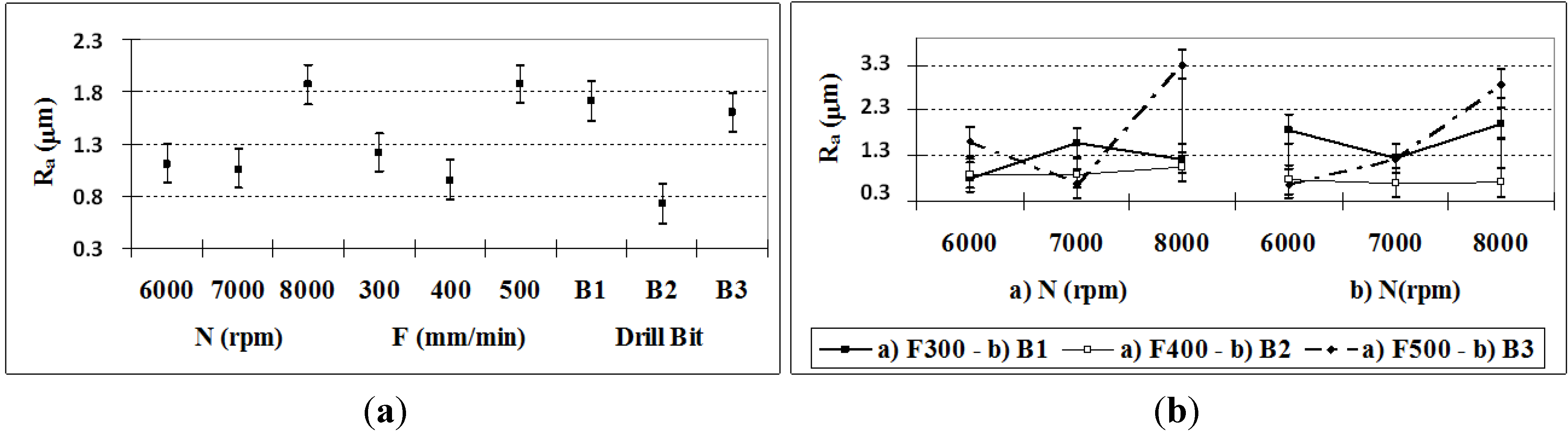

Mechanical and thermal properties of PEEK and PEEK GF30 - Download TableThe cutting parameters gotten from the sustainability index, does not correspond to the most financial option or the fastest, however allows that all the variables of the study at the same time (roughness, time, cost, tool life and energy) get a better commitment ... Did you see this? of the tool also has an essential impact on the results of forces, torques, and energy or power.