Spoke Holes

⚡ 👉🏻👉🏻👉🏻 INFORMATION AVAILABLE CLICK HERE 👈🏻👈🏻👈🏻

https://en.m.wikipedia.org/wiki/Spoke

Ориентировочное время чтения: 8 мин

When building a bicycle wheel, the spokes must have the correct length, otherwise there may not be enough threads engaged, producing a weaker wheel, or they may protrude through the rim and possibly puncture the inner tube.

Calculation

For bicycle spokes, the spoke length is defined from the flange seat to the thre…

When building a bicycle wheel, the spokes must have the correct length, otherwise there may not be enough threads engaged, producing a weaker wheel, or they may protrude through the rim and possibly puncture the inner tube.

Calculation

For bicycle spokes, the spoke length is defined from the flange seat to the thread tip. For spokes with bent ends, the nominal spoke length does not include the width of the spoke at the bent end.

For wheels with crossed spokes (which are the norm), the desired spoke length is

where

• d = distance from the center of hub (along the axis) to flange, for example 30 mm,

• r1 = spoke hole circle radius of the hub, for example 19.5 mm,

• r2 = half of effective Rim Diameter (ERD), or the diameter the ends of the spokes make in a built wheel (see 'Discussion' attached to this article for explanation) of the rim, for example 301 mm,

• r3 = radius of spoke holes in the flange, for example 1.1 mm,

• m = number of spokes to be used for one side of the wheel, for example 36/2=18,

• k = number of crossings per spoke, for example 3 and

• a = 360° k/m, for example 360°*3/18 = 60°.

Regarding d: For a symmetric wheel such as a front wheel with no disc brake, this is half the distance between the flanges. For an asymmetric wheel such as a front wheel with disc brake or a rear wheel with chain derailleur, the value of d is different for the left and right sides.

a is the angle between (1) the radius to a nipple hole in the rim to which a spoke is attached, and, (2) the radius to the flange hole holding the spoke. The spoke crosses either 1, 2, or 3 oppositely pointing spokes depending on the lacing design. On the flange, the angle between the radii of adjacent holes is 360°/m (for equally spaced holes). For each spoke crossed, the hub is rotated with reference to the rim one "angle between adjacent flange holes". Thus, multiplying the "angle between adjacent flange holes" by k gives the angle a. For example, a 32 spoke wheel has 16 spokes per side, 360° divided by 16 equals 22.5°. Multiply 22.5° ("angle between adjacent flange holes") by the number of crossings to get the angle a—if 3-crosses, the 32 spoke wheel has an angle a of 67.5°. Regarding r3: The size of the spoke holes in the flange does not matter for the needed spoke length. This term removes the effect of the hole size. Since the holes are usually small (just over 2 mm in diameter), the effect is small and in practice matters little.

For radially spoked wheels (zero crossings), the formula simplifies to the Pythagorean theorem, with spoke length l plus r3 being the slope, r2 minus r1 being the base, and d being the rise:

; or solving for the length

Derivation

The spoke length formula computes the length of the space diagonal of an imaginary rectangular box. Imagine holding a wheel in front of you such that a nipple is at the top. Look at the wheel from along the axis. The spoke through the top hole is now a diagonal of the imaginary box. The box has a depth of d, a height of r2-r1cos(α) and a width of r1sin(a).

Equivalently, the law of cosines may be used to first compute the length of the spoke as projected on the wheel's plane (as illustrated in the diagram), followed by an application of the Pythagorean theorem.

https://spokecalc.io/exotic-wheelbuilding.html

Перевести · 12.06.2019 · Spoke holes moved apart so that spokes of nearest pairs start to cross for another time. Basically we have moved each hole 28 …

https://www.sheldonbrown.com/spoke-length.html

Перевести · A double-wall rim has recessed spoke holes: the smaller holes closer to the center of the wheel hold the spokes. The larger holes in the wall which faces the tire allow access when building the wheel. Steps 2 and 3 in the list above are necessary with recessed spoke holes, …

https://m.youtube.com/watch?v=RFaGR8kcUyg

Перевести · For More information reach me at gaur_arvind@yahoo.com or call +91-9357773797

Drilling hub spoke holes For larger gauge spokes Bicycle MBRebel.com

Building a 16 Spoke Wheel with a 32 Hole Hub

How to Lace a Rim Without Access Holes (UST style)

https://neloscycles.com/Rims-Spokes-Hole

Перевести · Up for auction is(1) used Quando front hub only. The aluminum hubshell has 24 spoke holes and looks to be polished aluminum. The spoke holes are across from each other. …

https://dutchypatterns.com/jig-for-making-spoke-wheel-holes-on-a-drill-press-free-download

Перевести · Jig for making spoke wheel holes on a drill press (free download) Here you can download (ZIP file) two PDF drawings and some pictures of a simple jig for making holes in a spoke …

What are the two sides of a spoke hole?

What are the two sides of a spoke hole?

The two known sides (A and B) are the radius (half diameter) of the circle of spoke holes in the hub flange, and the radius of the circle of spoke holes of the rim. The angle θ depends on the number of spoke holes and the spoking pattern. The first step creates a virtual measuring point directly below the spoke holes in the rim.

www.sheldonbrown.com/spoke-length.html

Spokes are typically threaded through holes in the hub flange and attached the rim via little brass nipples which screw onto threads in the end of the spoke. The spokes are attached to the rim under tension, with this tension adjusted by screwing or unscrewing the nipples.

hub.chainreactioncycles.com/buying-guides…

Do you need to know the number of spokes on a wheel?

Do you need to know the number of spokes on a wheel?

You need to know the number of spoke holes of the rim and hub. Normally, these must match, though it is possible and sometimes useful to build a wheel with some mismatched combinations. We have an article about that.

www.sheldonbrown.com/spoke-length.html

How is the diameter of a spoke measured?

How is the diameter of a spoke measured?

If necessary, measure the depth from the measured diameter to a spoke hole; If necessary, calculate the rim's diameter where the heads of the spoke nipples rest in the spoke holes (called spoking diameter, equivalent rim diameter or E.R.D.) based on the measurements.

www.sheldonbrown.com/spoke-length.html

https://hub.chainreactioncycles.com/buying-guides/wheels-and-tyres/spokes-buying-guide

Перевести · 29.04.2020 · Spokes are typically threaded through holes in the hub flange and attached the rim via little brass nipples which screw onto threads in the end of the spoke. The spokes …

www.sturmey-archerheritage.com/files/view-1118.pdf

spoke 'e' HEAD through the hole in Rim, one hole anti-clockwise to spoke 'a' (i.e. to the left of spoke 'a') and through a slotted spoke hole …

Не удается получить доступ к вашему текущему расположению. Для получения лучших результатов предоставьте Bing доступ к данным о расположении или введите расположение.

Не удается получить доступ к расположению вашего устройства. Для получения лучших результатов введите расположение.

Measurements for Spoke Length Calculations

Please note Howard Sutherland's words of wisdom! To find the correct spoke length when building a wheel, you need dimensions of the rim and hub. There are manufacturers' specifications and lists of rim and hub dimensions online -- including Damon Rinard's list on this site, BUT, only after you have mostly laced up a wheel will you discover whether spoke length is correct. So, measure, even if you think you know the correct dimensions. Online information is, to be sure, useful in identifying parts and in confirming your measurements.

This article describes how to measure, with an emphasis on the use of simple, low-cost tools, and describes the level of accuracy needed.

Spoke lengths are given in millimeters, so you need to come up with measurements in millimeters. Some of the measurements in this article use a tape measure divided in inches, and the article shows how to convert to millimeters.

You may skip over this section in case you like. You don't have to know the formula for spoke length. Spoke length calculator software does the number crunching for you.

But in case the math interests you, here's how spoke length is calculated. It's a problem in trigonometry, in two steps.

The first step is to calculate the length of the third side of a triangle according to the cosine rule formula,

_________________

C = \/A2 + B2 - 2AB cos θ

A is indicated by the purple line in the illustration at the left, and B by the orange line. C (in red) is the third side, the one you calculate.

The two known sides (A and B) are the radius (half diameter) of the circle of spoke holes in the hub flange, and the radius of the circle of spoke holes of the rim. The angle θ depends on the number of spoke

holes and the spoking pattern.

The first step creates a virtual measuring point directly below the spoke holes in the rim. There's nothing to measure directly there, and that's why a second step is needed.

The second step gives the spoke length, by accounting for the spacing of the hub flange away from the centerline. This step applies the Pythagorean Theorem for the hypotenuse (slant side) of a right triangle, with a slight correction to account for the size of the spoke holes in the hub:

Each of the hub's two flanges may be a different distance from the centerline, as indicated by the blue and green lines -- image modified from one by keithonearth on Wikipedia.

When taking measurements, record the following information. You need this information to do your calculation, and to make a correction for the next wheel, if the spoke length turns out slightly incorrect with your first one.

You need to know the number of spoke holes of the rim and hub. Normally, these must match, though it is possible and sometimes useful to build a wheel with some mismatched combinations. We have an article about that. If the hub is very large, as with many electrically-assisted bicycle hub motors, that article will show how to reduce spoke angle at the rim and avoid spoke breakage.

Also, some hubs and rims have unevenly-spaced spoke holes, but we're not going to discuss them here. We'll have another page for them soon!

Measuring a rim is usually done in three steps:

A rim may have a single-wall or double-wall cross-section, as shown in the image below. A double-wall rim has recessed spoke holes: the smaller holes closer to the center of the wheel hold the spokes. The larger holes in the wall which faces the tire allow access when building the wheel.

Steps 2 and 3 in the list above are necessary with recessed spoke holes, because you can't measure the spoking diameter directly.

The illustration below shows the outside diameter and the spoking diameter. The rim shown is a double-wall rim with recessed spoke holes and no eyelets.

Cross section showing rim outside diameter

and spoking diameter. The spokes attach

at the deeper, smaller holes in this double-wall rim.

Lay a measuring tape or ruler across the rim between two points directly opposite one another. Slide one end of the tape back and forth along the rim until the measurement is largest. Measure at three or four different angles spaced equally around the rim and take the average, in case the rim isn't perfectly round. (Spoke tension will make the rim round later, unless the rim is really bad. Then start with another rim.) Measure to the nearest 1mm or 1/32 inch, or better. If the diameter falls partway between millimeter or 1/32 inch marks on the tape, you could estimate the fraction.

If you measured in inches, multiply by 25.4 to get the diameter in millimeters. Convert the fraction after the last even inch to a decimal before multiplying: for example, 1/4" is 0.250, so a rim that measures 24 1/4 inches is 24.250 inches in diameter, or rounded to the nearest 1/10 millimeter, 616.0 mm. .

If you are working with an empty rim, it is easy to measure the outside diameter, but if you need to measure a built-up wheel, the axle gets in the way of the tape measure. You then need to measure the circumference (distance around the rim). Also, measuring in two different ways is possible, and a good idea. As carpenters say, "measure twice and cut once" or in this case, measure twice and select spokes once.

You can measure the circumference of a rim by wrapping a measuring tape all the way around the rim. You then derive the diameter from the circumference.

A narrow, metal tape measure -- 1/4 inch or 6 mm wide -- will fit into the well of the rim (the deepest part of the rim's channel). (A wide metal tape measure won't fit into the well of most rims and won't curve smoothly around the rim.)

Don't trust a fabric measuring tape as used in fitting clothing. The fabric stretches.

Use the metal tape measure as shown in the image below.

Here are the steps to measure a rim using the circumference:

If you don't have a narrow tape measure, you could wrap a bicycle cable inner wire around the rim, hooking the ferrule into the valve hole. Mark the wire, stretch it out flat and measure the length. If measuring a built-up wheel with non-recessed spoke nipples, the cable will sit next to them and the measurement is that for a bare rim.

You must measure the depth to the spoke holes if they are recessed, or if you measured the outside diameter of the rim.

You can use an improvised tool, as in the image at the right -- a bolt and nut, and a small metal ruler. Lay the ruler flat across the flanges of the rim. I

nsert the bolt. If the rim has recessed spoke holes, the bolt will extend to the bottom of an eyelet. Screw down the nut until it rests against the ruler. Then use the ruler to measure the length between the nut and the end of the bolt. Subtract the thickness of the ruler (here, about 0.5 mm). Again, if your ruler only measures in inches, you need to convert to millimeters.

To avoid having to remove the rim tape of a built-up wheel, you may measure at the inside of the valve hole, as long as you can see that the spokes rest at the same diameter.

If you measured the circumference of the rim at the well, then measure the depth from the well to a recessed spoke hole, if the spoke holes are recessed.

If you are good at holding objects steady in your hands, you can even do the depth measurement with a bare bolt or bicycle spoke, as shown in the image at the left. Insert the spoke to the bottom of the spoke-hole recess, and slide your hand down the spoke until the fingernail of your index finger rests lightly against the side of the access hole.

Then as shown in the image at the right, transfer this measurement to the ruler, resting your fingernail lightly against its end.

The dimension you measured using the bolt or spoke is a difference in the radius --the distance from the center of the wheel to the outside. Spoke calculators use the diameter, which is twice the radius, because there's nothing to measure at the center of an empty rim. So, as you move on to final calculations, you'll be subtracting twice the depth you measured with the bolt or spoke.

Now you need calculate the spoking diameter. Get out your pocket calculator or smartphone app (or a paper and pencil if you're retro or the battery is dead).

We'll calculate our spoking diameter using both of our sets of measurements, and see how the results compare.

The measured outside diameter of our rim is 20 7/8 inches, or 20.875 inches. Multiplying by 25.4 gives 530.2 mm. The measured depth from the outside of the rim to the spoke hole is 11 mm. Twice that is 22 mm, and so the spoking diameter measures as 508.2 mm.

The circumference of the well measures as 64 1/8 inches, (64.125 inches). Multiplying by 25.4 converts to 1629 mm; then dividing by pi, the diameter at the well is 518.5mm. The depth of the recessed spoke holes is 5mm; twice that is 10mm and so the spoking diameter measures as 508.5mm.

So, we got 508.2 mm by measuring the diameter and 508.5 mm by measuring the circumference. Close enough!

Finally: If you measured over the tops of spoke nipples, you are done. If you measured an empty rim, add twice the height of a spoke nipple -- about 4mm total. This measurement should agree with the one according to Damon Rinard's method (see below).

Damon Rinard describes another method to calculate rim diameter, but I think it is more complicated.

The handy Sutherland Rim Diameter System simplifies measurement of the rim. By using a tape with a special scale, this system calculates the diameter for you -- saving time, and time is money if you build a lot of wheels. The Sutherland system includes a tool to find the effective rim diameter for spoking.

Howard Sutherland demonstrates the Rim Diameter System in the video below:

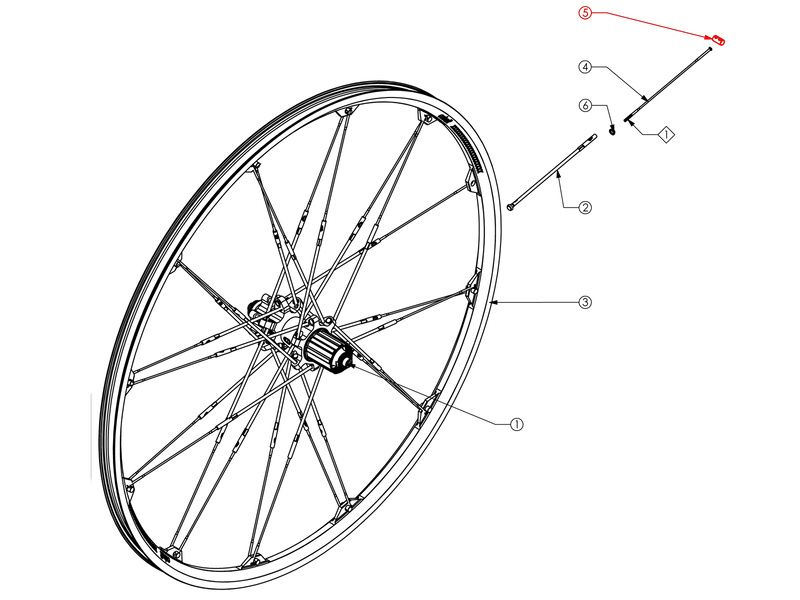

To determine spoke length, you also need measurements of the hub: the diameter of the circle of spoke holes, the diameter of a spoke hole, and the flange spacing from the centerline.

The axle gets in the way when measuring the diameter of the circle of spoke holes (d in the image at the right). The spoke hole diameter (S) also affects spoke length.

The traditional way to measure the spoke hole circle diameter is with a caliper, as shown in the image below, center to center of the spoke holes, but it's easier to measure from the right side to the right side, or left side to left side. You can't get a "contact" measurement this way, but inaccuracy of a small fraction of a millimeter isn't going to be important here. If you're a real stickler, you could insert the outside-measuring blades of the caliper into the spoke holes to take a smaller measurement, and the inside-measuring blades (at the top in the picture) to do a larger measurement, then take the average. Subtracting the smaller from the larger measurement and dividing by two would also give you the diameter of the spoke holes -- but that is usually 2.5 to 3 mm, and the resulting difference in spoke length isn't large enough to matter.

You don't need a caliper. You could cut a C-shaped recess in a piece of cardboard, mark the spoke-hole spacing as shown in the photo at the left, and then measure it with a ruler.

A hub flange farther from the centerline requires longer spokes, but only slightly longer with most wheels because the spokes approach the hub at a high angle.

Usually with a front wheel or the left side of rear wheel, you can go with a typical spacing of 35 mm, and with the right side of a rear wheel that has multiple sprockets, 20 mm.

The drawing below is of the same hub shown in the previous two photos (a SRAM DualDrive hub, a 3-speed with a cassette body for hybrid gearing). The dimension in red is the OLD (overlocknut distance), and the dimensions in blu

Nylon Handjob Mature

Handjob Two Dicks

Straight Shota Handjob

Mom Hairy French Porno

Free Young Teen Porn Videos

Spoke - Wikipedia

Exotic wheelbuilding: Understanding paired spoke ho…

Measurements for Bicycle Spoke-Length Calculations

Aluminium Rim Spoke Hole Drill - YouTube

Rims - Spokes Hole - Nelo's Cycles

Spoke Wheel Jig - Dutchy Patterns

Best Bike Spokes | Buying Guide | Chain Reaction Cycles

COMPLETE WHEEL-BUILDING INSTRUCTIONS

Spoke Holes