Some Of "Friction vs. Performance: Exploring the Benefits of Reducing Resistance"

Unlocking Efficiency: The Science of Friction Reduction

Rubbing is a pressure that resists activity between two surface areas that are in get in touch with with each other. It plays a considerable duty in several facets of our day-to-day lives, coming from the way we relocate to the equipments we use. Understanding and minimizing rubbing has been a long-standing goal for scientists and designers, as it stores the secret to unlocking performance in a wide variation of applications.

Premium full synthetic oil can easily be both valuable and damaging, depending on the circumstance. On one hand, it allows us to walk, drive vehicles, and also keep objects firmly. On the various other hand, friction leads to wear and tear on technical parts, resulting in power losses and reduced productivity. In fields such as vehicle manufacturing, aerospace design, and renewable power production, lowering rubbing can have considerable economic and ecological benefits.

The science responsible for friction reduction includes understanding the factors that contribute to this pressure. The primary factors include surface area roughness, adhesion, lubrication, temperature, and velocity. By adjusting these aspects via scientific strategies and design approaches, researchers have produced substantial development in lessening frictional reductions.

One strategy to reducing friction is through improving area level of smoothness. When two surfaces happen right into call with each various other at a minuscule degree, irregularities on their surface areas can interfere along with smooth moving or rolling motion. By buffing or finishing surface areas along with materials like diamond-like carbon dioxide (DLC), scientists have been able to lessen surface area roughness considerably. This approach has found functions in numerous industries like auto production and accuracy design.

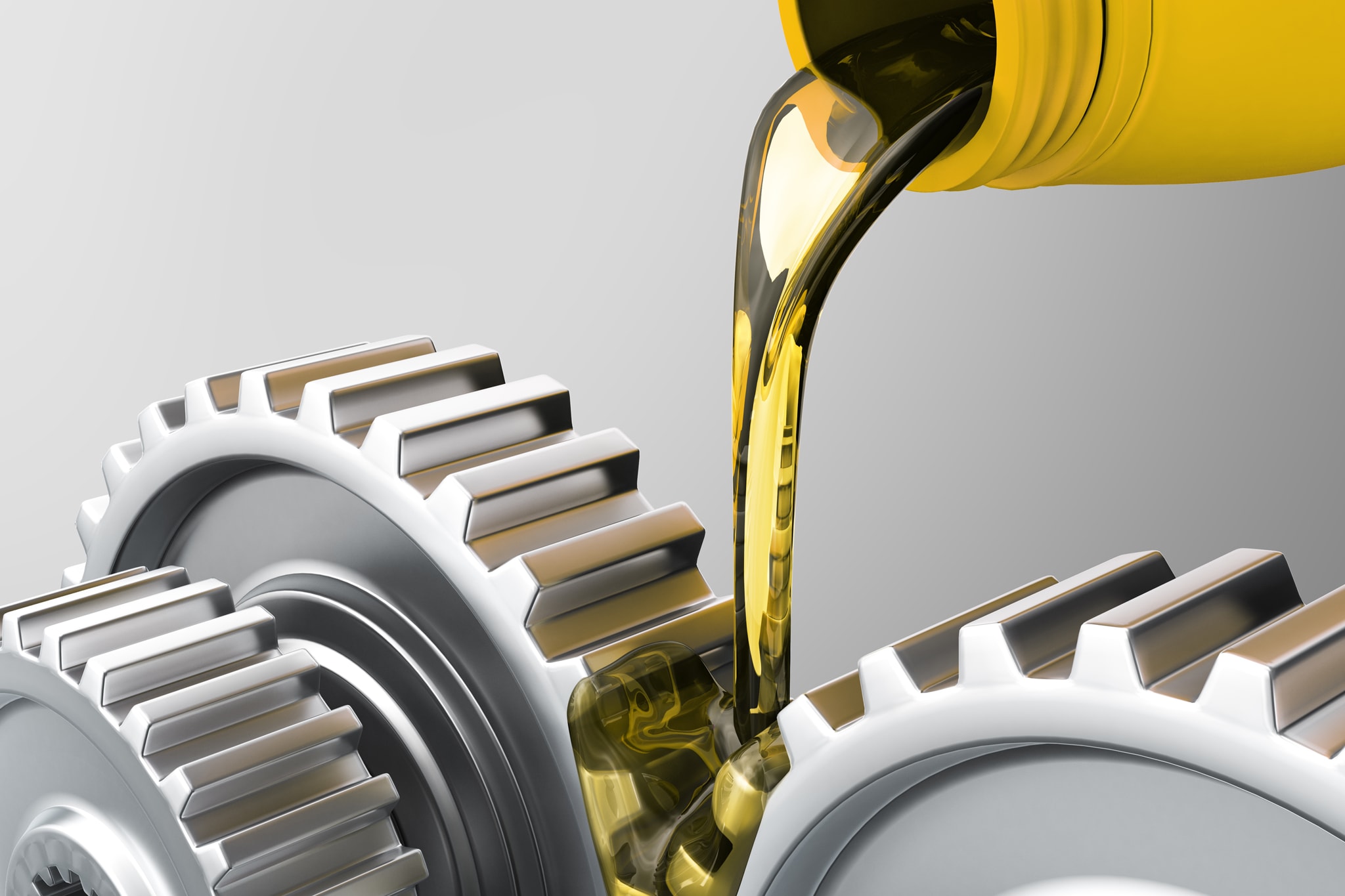

Yet another technique used for abrasion decline is lubrication. Lubricating substances function as middlemans between two surfaces in get in touch with by forming thin films that separate them. These movies lower straight connect with between the surfaces, therefore reducing frictional pressure substantially. Different types of lubricants are utilized relying on the application demands – ranging coming from oils and greases for machinery to specialized layers for high-temperature atmospheres such as plane engines.

Adherence, the molecular power that keeps two surface areas with each other, can easily also add to abrasion. By tweaking area chemistry and utilizing anti-adhesive finishes, scientists have been able to lessen the attachment between areas, leading to lower frictional power. This approach has located apps in different fields where sticking and adherence are bothersome, such as medical units and manufacturing methods.

Temperature level participates in a vital job in friction decline. As temperature level increases, products extend and become more flexible, leading in reduced rubbing. In some cases, cooling systems are employed to preserve lower temperatures and strengthen effectiveness. For instance, in high-speed machining procedures or power creation turbines, cooling is necessary to prevent extreme heat buildup and decrease friction-related losses.

Rate is an additional aspect that affects friction. At higher speeds, the interaction between surfaces ends up being even more complicated due to elements like liquid dynamics and connect with stress and anxieties. Understanding these phenomena makes it possible for experts to create far better greasing devices or modify surface properties for optimum efficiency at different velocities. This knowledge has been crucial in improving the efficiency of numerous transportation systems like cars and trucks, learns, and planes.

Initiatives in the direction of minimizing rubbing have also led to innovations in materials science. Analysts are cultivating brand-new components along with superior residential properties that show reduced friction under details health conditions. For example, self-lubricating plastics or complex products having nanoparticles may deliver low-friction qualities without the necessity for outside greasing.

In verdict, unlocking productivity by means of the scientific research of friction decline is a multidisciplinary undertaking that entails understanding various aspects adding to this power. By researching surface area roughness, adherence homes, oiling procedures, temp impacts, speed factors to consider, and product scientific research advancements – experts and engineers have produced significant improvement in lessening frictional losses across several business. Continuous analysis in this area are going to definitely lead to further enhancements in productivity while promoting maintainable strategies for a greener future.

Word Count: 800