Slim Tube Test

🛑 👉🏻👉🏻👉🏻 INFORMATION AVAILABLE CLICK HERE👈🏻👈🏻👈🏻

A laboratory test used to estimate the minimum miscibility pressure (MMP) or minimum miscibility concentration (MMC) of a given injection solvent and reservoir oil. The slim tube is a long coiled tube filled with sand of a specific mesh size or similar porous media. The tube is saturated at the beginning of each test with reservoir fluid at a given temperature. Solvent injection is performed at several test pressures. Effluent production, density and composition are measured as functions of the injected volume. Oil recovery after injection of a specific number of pore volumes (PV) such as 1.2 PV of solvent is the test criterion for miscibility. Two trend lines appear on a plot of recovery versus pore pressure for several slim-tube tests. The point of intersection of those trend lines is the estimated MMP for the given oil-solvent system. The data from a slim tube test can also be used as input to fine-tune a fluid equation of state for reservoir simulation.

To download this file you first sign in to your Schlumberger account.

Don't have an account? Click below to get started.

Premium content requires special account permissions. We need a little more information from you before we can grant you access.

Email Us

Send us a Request

24 Hour U.S. Wellsite Service & Sample Pick-up Hotline

Call Us

Houston, Texas

Phone: 1-713-328-2673

Calgary, Alberta

Phone: 1-403-250-4000

Aberdeen, Scotland

Phone: 44-12-2442-1000

Perth, Australia

Phone: 61-08-9353-8888

Abu Dhabi, UAE

Phone: 971-2-555-4428

Bogota, Colombia

Phone: 57-1-674-0400

Locations

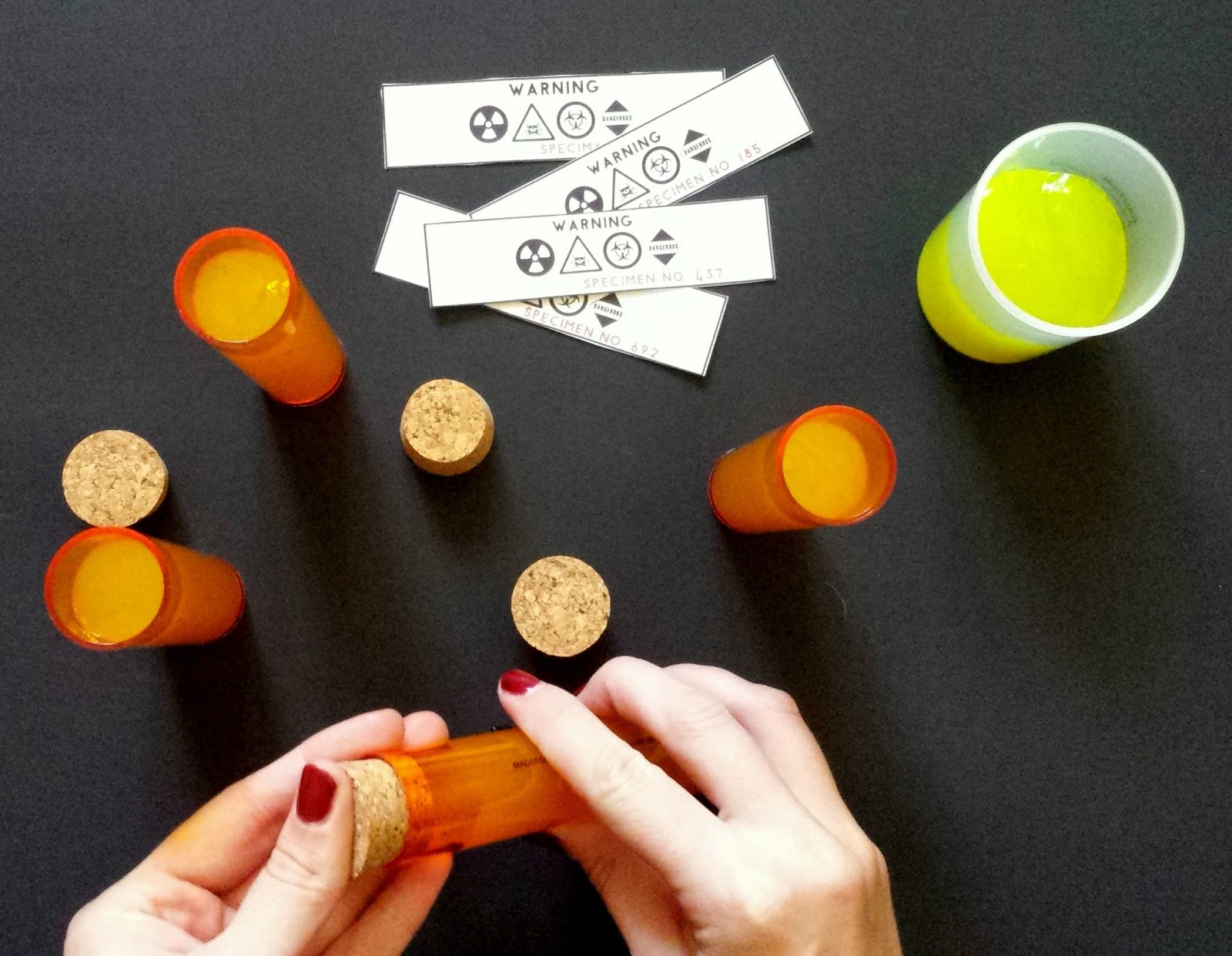

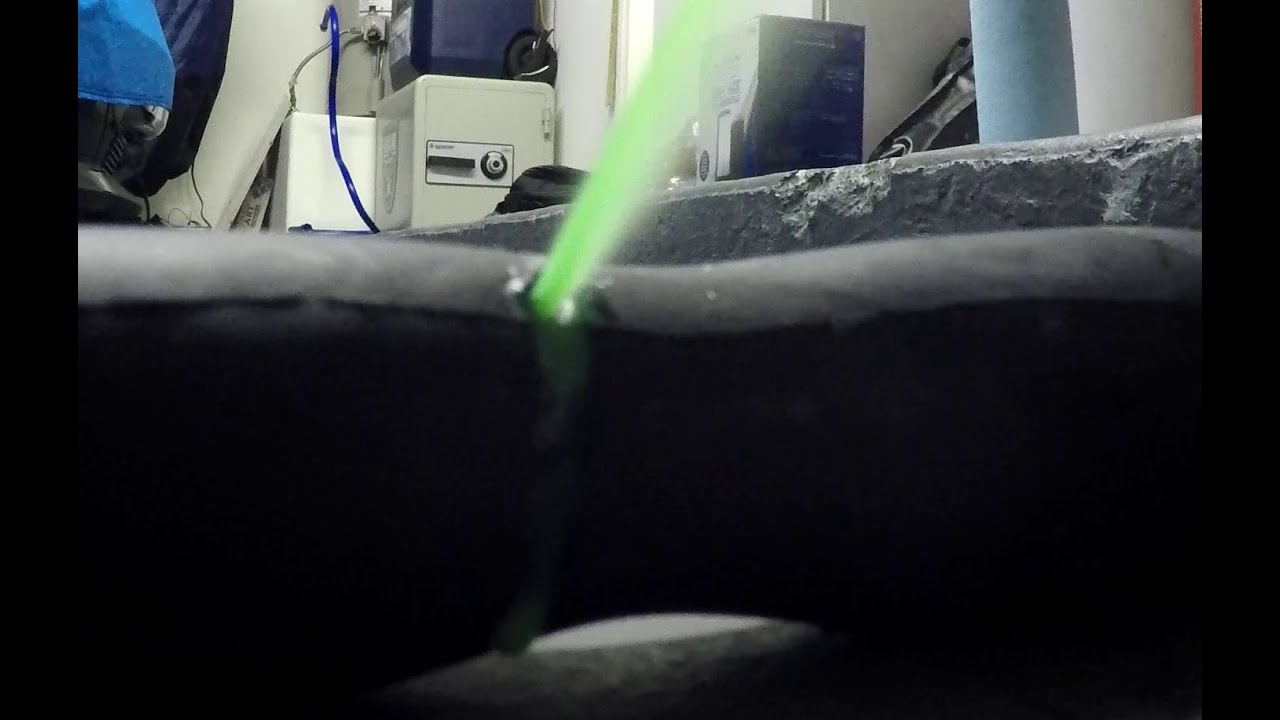

A slim tube miscibility test is performed using the equipment set-up as shown. Typically the test is performed within a 40 foot column pre-packed (glass beads or Ottawa sand) ¼" OD length of coiled stainless steel tubing. Columns with different lengths and packing materials can be used upon request. The porosity and permeability of the column is measured at the beginning of each suite of analyses. The column is cleaned, evacuated and weighed before commencing the test procedure.

A windowed PVT cell and camera can be added to the set-up to visually observe the time at which gas breakthrough occurs. A high pressure densitometer can also be added to measure the density of effluent fluid.

The column / lines are pre-charged with toluene and system heated to the requested test temperature.

Reservoir fluid is injected into the column and toluene is displaced out of other end by controlling the column end-pressure, using a backpressure regulator (BPR). After 1.5 pore volume of fluid has been injected, gas and liquid collection apparatus are connected prior to displacing further fluid. A further 10 ml of fluid is displaced to collect fluid for liquid density measurement and GOR calculation. The data is compared to the original atmospheric flash data on the reservoir fluid sample. When the data agrees with the original measurements the test can commence.

The test gas is injected at an initial rate of 6 ml per hour and the evolved products are continuously collected. The evolved gas volume, weight and residual liquid density is measured every hour. The composition of the evolved products can be measured if requested by the client. The gas injection rate continues at 6 ml per hour, for 6 hours and then it is increased to 8 ml per hour for the remainder of the test. The exact point of gas breakthrough will be clearly observed by a significant increase in GOR, decrease in residual liquid density and change in gas composition/gas gravity.

The test continues until 1.4 pore volume of test gas has been injected into the coil. The remaining gas within the coil is "blown down" and the atmospheric volume recorded. Any residual oil produced during this process is also collected and weighed. The coil is then disconnected and weighed to determine the weight of residual oil remaining at the end of the test.

The test is normally performed at between 4 to 6 test pressures. A plot of recovered oil volume at 1.0 or 1.2 pore volumes versus test pressure will indicate the minimum miscibility pressure of the reservoir fluid, for the selected injection gas composition.

We use cookies for you to have the best experience of our website. By your continued use of our website you agree to Core Lab's usage of cookies. More Information

Yes, I Accept Cookies No, I Do Not Accept Cookies

Judas Priest Private Property

Xxx Incest Pedophilia Childrens Gif

Fisting Play Lesbian

Mom Kissing Porno

Chained Fury Lesbian Slave Desires

slim-tube test | Oilfield Glossary

Core Laboratories: Minimum Miscibility - Slim Tube

Evaluation Of Miscibility From Slim Tube Tests | Journal ...

پتروآزما - PetroAzma - Slim Tube Test

Slim Tube Test versus RBA Method | Fundamentals of Fluid ...

Laboratory Factors Influencing Slim Tube Test Results ...

Slim Tube | СШ №5 | ВКонтакте

slim tube test

Slim Tube Test

.jpg)