Shielded Cable for Electrical Applications A Comprehensive Guide

Introduction

In the field of electrical engineering and electronics, shielded cables play a crucial role in ensuring proper signal integrity, reducing electromagnetic interference (EMI), and enhancing overall system performance. Shielded url are designed with an additional layer of shielding material to protect the signal-carrying conductors from external interference and to prevent the emission of electromagnetic radiation. This comprehensive guide will delve into the various types of shielded cables, their construction, applications, advantages, and considerations for selecting the right shielded cable for specific electrical applications.

Types of Shielded Cables

1. Foil Shielded Cable: Foil shielded cables consist of a thin layer of aluminum or copper foil wrapped around the insulated conductors. The foil shield provides excellent protection against high-frequency electromagnetic interference and is often used in applications where flexibility and lightweight construction are essential.

2. Braided Shielded Cable: Braided shielded cables feature a woven mesh of metal strands, typically made of copper, surrounding the inner conductors. The braided shield offers superior flexibility, durability, and protection against low-frequency interference. Braided shielded cables are commonly used in industrial environments and high EMI settings.

3. Combination Shielded Cable: Combination shielded cables combine the benefits of both foil and braided shielding to provide enhanced EMI protection across a wide frequency range. These cables are well-suited for applications requiring comprehensive shielding performance, such as medical equipment, aerospace systems, and data centers.

4. Spiral Shielded Cable: Spiral shielded cables feature a helical winding of metal wire around the inner conductors, offering effective EMI protection while maintaining flexibility and ease of installation. Spiral shielded cables are suitable for applications where space constraints and mechanical stress are considerations.

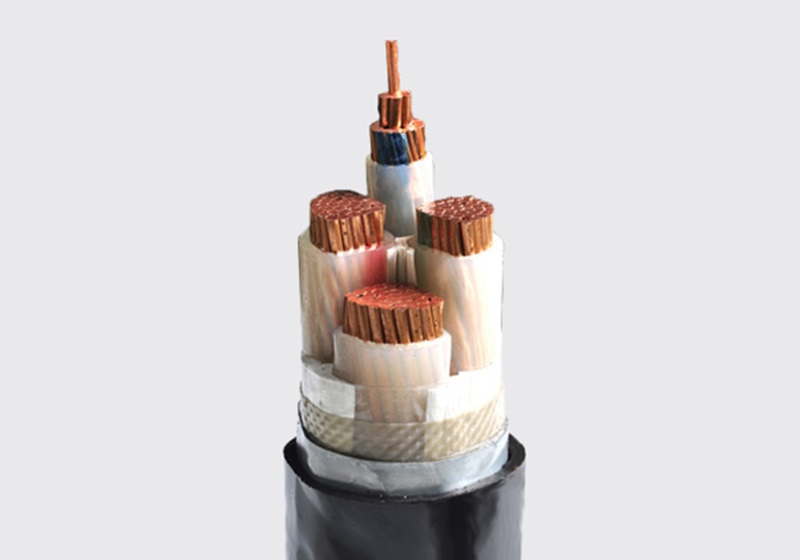

Construction of Shielded Cables

Shielded cables consist of several key components that work together to ensure reliable signal transmission and protection against interference. The primary components of a shielded cable include:

1. Conductor: The conductor is the core component of the cable responsible for carrying electrical signals from one point to another. Conductors are typically made of copper or aluminum due to their excellent conductivity properties.

2. Insulation: Insulation material surrounds the conductors to prevent short circuits and ensure electrical safety. Common insulation materials include PVC (polyvinyl chloride), PE (polyethylene), and XLPE (cross-linked polyethylene).

3. Shielding: The shielding layer in a shielded cable serves to protect the conductors from EMI and RFI (radio-frequency interference). Depending on the type of shielded cable, the shielding material can be a foil, braid, or combination of both.

4. Jacket: The outer jacket of the cable provides mechanical protection, insulation, and resistance to environmental factors such as moisture, abrasion, and chemicals. Jacket materials vary depending on the application requirements and can include PVC, PUR (polyurethane), or TPE (thermoplastic elastomer).

Applications of Shielded Cables

Shielded cables find widespread use across various industries and applications where reliable signal transmission and EMI protection are critical. Some common applications of shielded cables include:

1. Industrial Automation: Shielded cables are essential in industrial automation systems to ensure the integrity of control signals, data communication, and power distribution. These cables are used in PLCs (programmable logic controllers), sensors, actuators, and other industrial equipment.

2. Telecommunications: In the telecommunications sector, shielded cables are used for transmitting voice, data, and video signals with minimal interference. Applications include telephone lines, networking cables, fiber optics, and satellite communications.

3. Medical Equipment: Shielded cables are employed in medical devices and equipment to maintain signal accuracy and prevent interference that could affect patient safety. Examples include MRI machines, patient monitoring systems, and diagnostic instruments.

4. Aerospace and Defense: The aerospace and defense industries rely on shielded cables for avionics, radar systems, communication networks, and electronic warfare applications. Shielded cables ensure secure and reliable data transmission in harsh operating environments.

5. Audio and Video Systems: Shielded cables are commonly used in audio/video systems to minimize electromagnetic interference and deliver high-quality audio and video signals. Applications include home theaters, recording studios, broadcast facilities, and multimedia installations.

Advantages of Shielded Cables

Shielded cables offer several key advantages over unshielded cables, making them the preferred choice for critical applications that require reliable signal transmission and EMI protection. Some of the advantages of shielded cables include:

1. EMI Protection: Shielded cables effectively block external electromagnetic interference, preventing signal degradation and ensuring consistent performance in high EMI environments.

2. Signal Integrity: By reducing noise and crosstalk, shielded cables help maintain signal integrity and minimize data errors, resulting in improved system reliability and performance.

3. Flexibility: Depending on the type of shielding used, shielded cables can offer flexibility and ease of installation without sacrificing EMI protection, making them suitable for applications with tight spaces or complex routing requirements.

4. Durability: Shielded cables are designed to withstand mechanical stress, environmental factors, and harsh operating conditions, ensuring long-term reliability and performance in demanding applications.

Considerations for Selecting Shielded Cables

When choosing a shielded cable for a specific electrical application, several factors must be taken into account to ensure optimal performance and compatibility. Some key considerations include:

1. EMI Requirements: Identify the level of electromagnetic interference present in the application environment and select a shielded cable with the appropriate shielding type (foil, braid, or combination) to meet the EMI protection requirements.

2. Frequency Range: Consider the frequency range of the signals being transmitted through the cable and choose a shielded cable with shielding properties that effectively attenuate interference across the required frequency spectrum.

3. Voltage Rating: Ensure that the shielded cable's voltage rating matches the system voltage requirements to prevent electrical breakdown and ensure safe operation under all conditions.

4. Environmental Conditions: Evaluate the operating environment for factors such as temperature extremes, moisture, chemicals, and mechanical stress, and select a shielded cable with a jacket material that can withstand these conditions.

5. Installation Requirements: Consider the installation method, bending radius, and cable routing constraints to choose a shielded cable that offers the necessary flexibility, ease of installation, and protection against mechanical damage during deployment.

Conclusion

Shielded cables play a crucial role in modern electrical and electronic systems by providing reliable signal transmission, EMI protection, and enhanced system performance. With various types of shielded cables available, each offering unique advantages and applications, it is essential to select the right cable for specific requirements based on factors such as EMI protection, signal integrity, flexibility, durability, and environmental considerations. By understanding the construction, applications, advantages, and considerations associated with shielded cables, engineers and designers can make informed decisions to ensure the success of their electrical projects and systems.