Rubber Strips – Today's Industrial Absolute Solution

Vaishali AegisRubber is a material on which the contemporary world is strongly reliant. Both natural and synthetic rubbers have their own significance and are used in a wide range of sectors in the production of a wide range of different goods. There are so many things that use either synthetic or natural rubber that you may be able to locate a lot of them if you take a look around. At home, at work, in your vehicle, and in sports equipment that you use on a daily basis, you will quickly come across a variety of rubber goods that you may utilise.

Rubber materials, despite the fact that they are more costly, last far longer and need significantly less care than typical rubber materials. Rubber stripes are more heat retardant, more robust, and far less likely to experience damaged from intense weather and drastic temperature fluctuations than other types of roofing materials. While most rubber manufacturers provide guarantees on their goods for 30 to 50 years the most prevalent roofing material, only lasts 15-20 years and needs more care than rubber. EPDM rubber is a form of synthetic rubber that is used in a variety of applications. Being exceptionally durable and flexible, it may be utilised in a broad variety of applications, including automobiles (where it is used for exterior and interior seals, and cooling system tubes), cold rooms, non-skid decking and playground surfaces, and a variety of other places. Pure rubber turns brittle when exposed to temperature fluctuations, but synthetic rubber (EPDM) remains flexible and can resist temperature fluctuations for centuries.

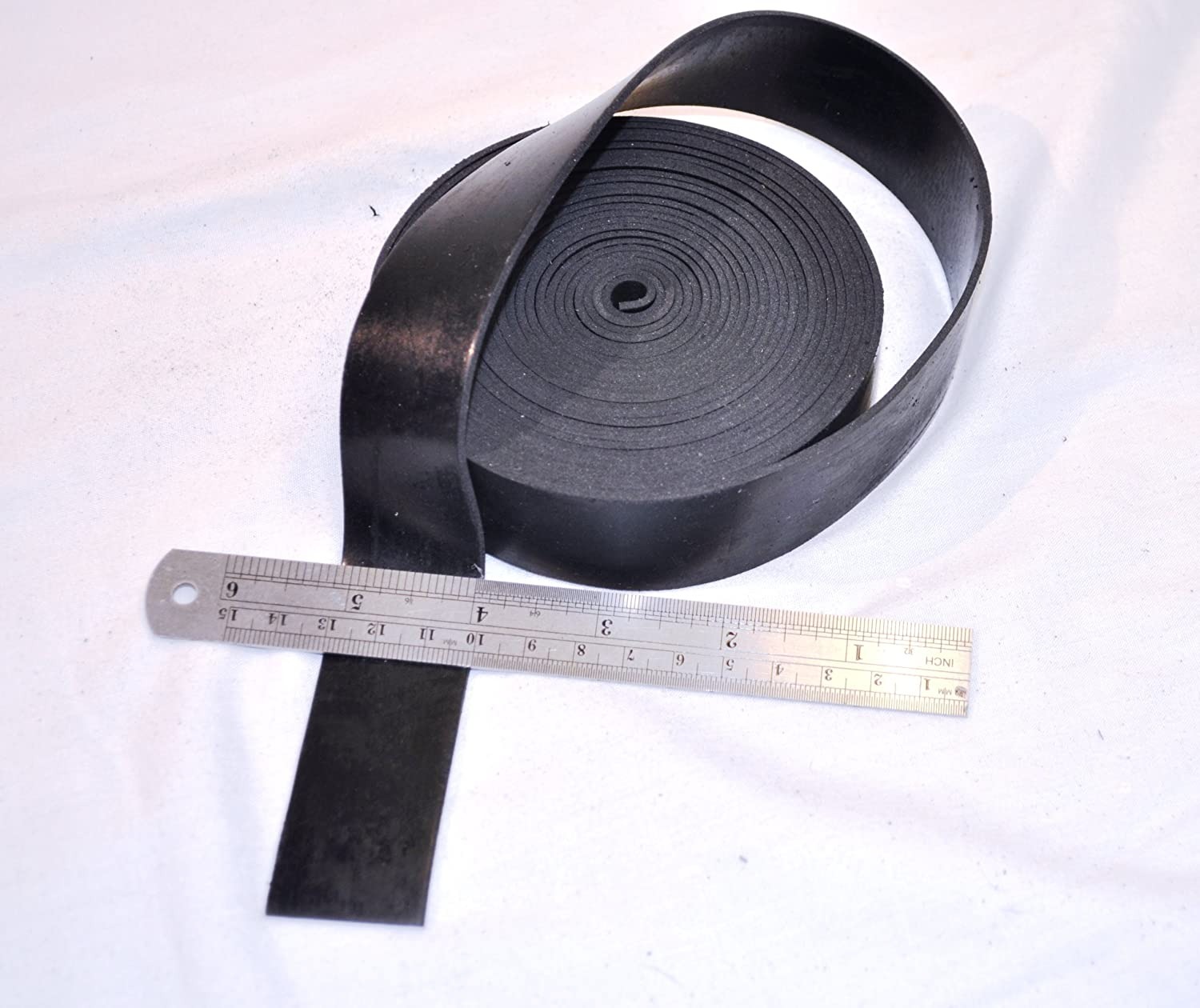

Rubber strips are that is either composed of rubber or fabric that has been coated with rubber. There is a large range of rubber sheets available on the market, and determining which one is the most suited may be a difficult process. Before picking a certain kind of sheet, be sure that its length, breadth, and thickness are all appropriate for your needs. Rubber Strips are now widely accessible on the market, in a variety of shapes, sizes, and requirements. This variety is created in order to make them appropriate for a variety of different uses.

The substantial industrial knowledge and skill that rubber strips India have in this field allows them to provide a high-quality assortment of EPDM rubber strips that are excellent in terms of UV stability, good resistance to cracking, and great strength when it comes to cracking. This product is made from high-quality materials and the necessary amenities, and it is constructed in accordance with industry standards. They provide this EPDM rubber strip in a variety of thicknesses and designs in order to meet the needs of the customers, who are located all over the world.

Features:

1. Usage that is effective

2. Exceptional efficacy

3. Nature is dependable.

Manufacturing of rubber products starts with the preparation of a rubber mix consisting of raw and/or synthetic rubber, carbon black (the principal filler used in the preparation of a rubber combination), oils, and other assorted chemicals. Some of rubber strips India characteristics include its adaptability for a variety of applications, such as glazing seals, door gaskets, gap fillers, helmet seal, as well as other types of sealing.

Rubber seal strip are utilised in a broad range of applications in a variety of areas. Their Rubber seal strip provide great resistance and sealing for applications involving cooler temperatures, low pressures, and moderate chemical conditions, among other things. Rubber, both natural and synthetic, is available in sponge stripe form (cellular rubber), which is available in both open and closed cell grades in most cases. Neoprene, nitrile, silicone, and Viton are all available in sponge from rubber manufactures. Closed cell sponge is offered for applications needing high compressibility, but open cell sponge is accessible for cushioning applications where sealing is not a concern, such as in medical devices.