Metal Foil Resistors-Problem associated with glue and metal foil. 1

Charly GarcíaThis document is related to the document "Metal Foil Resistors" , https://telegra.ph/Metal-Foil-Resistors-1-07-15

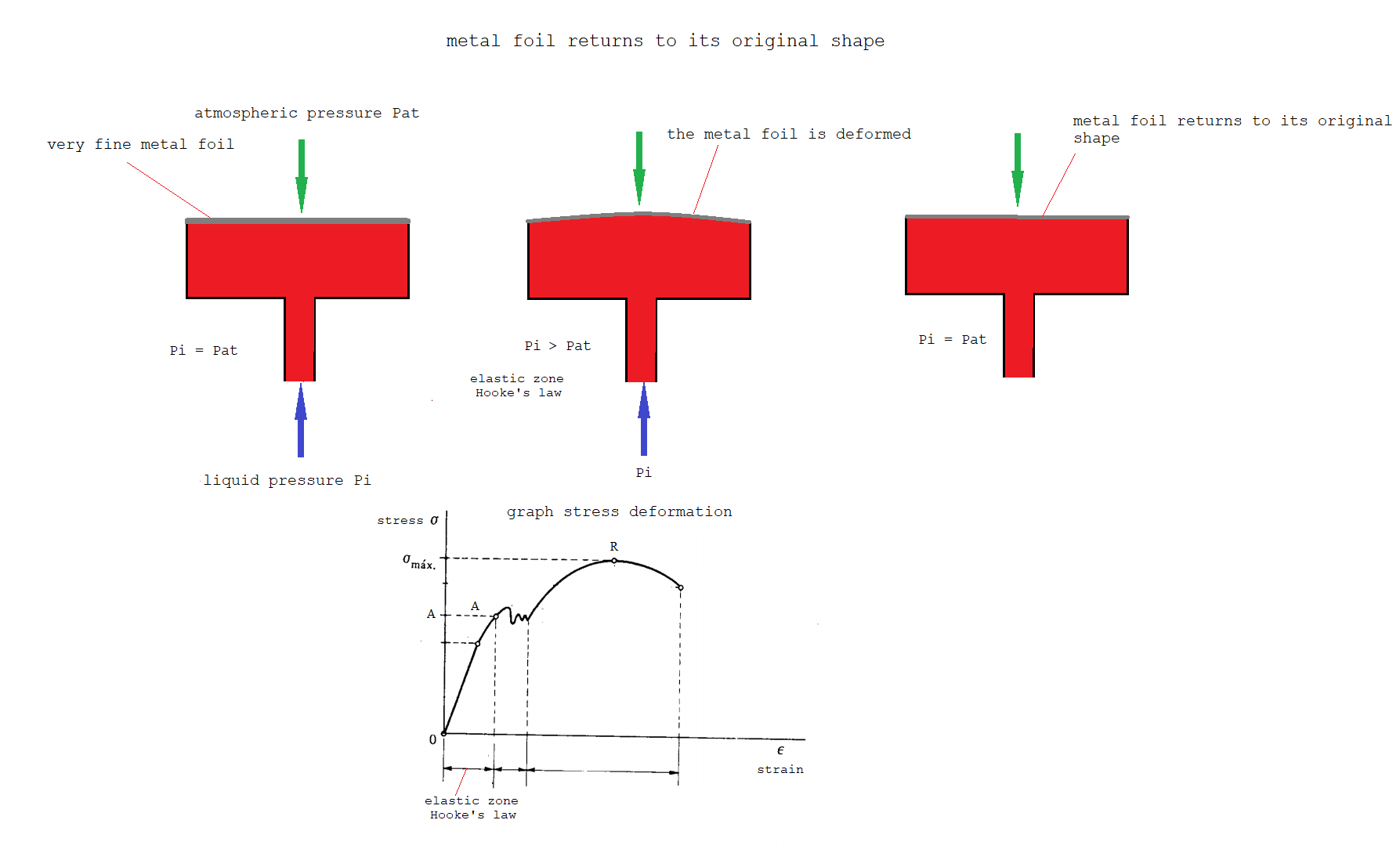

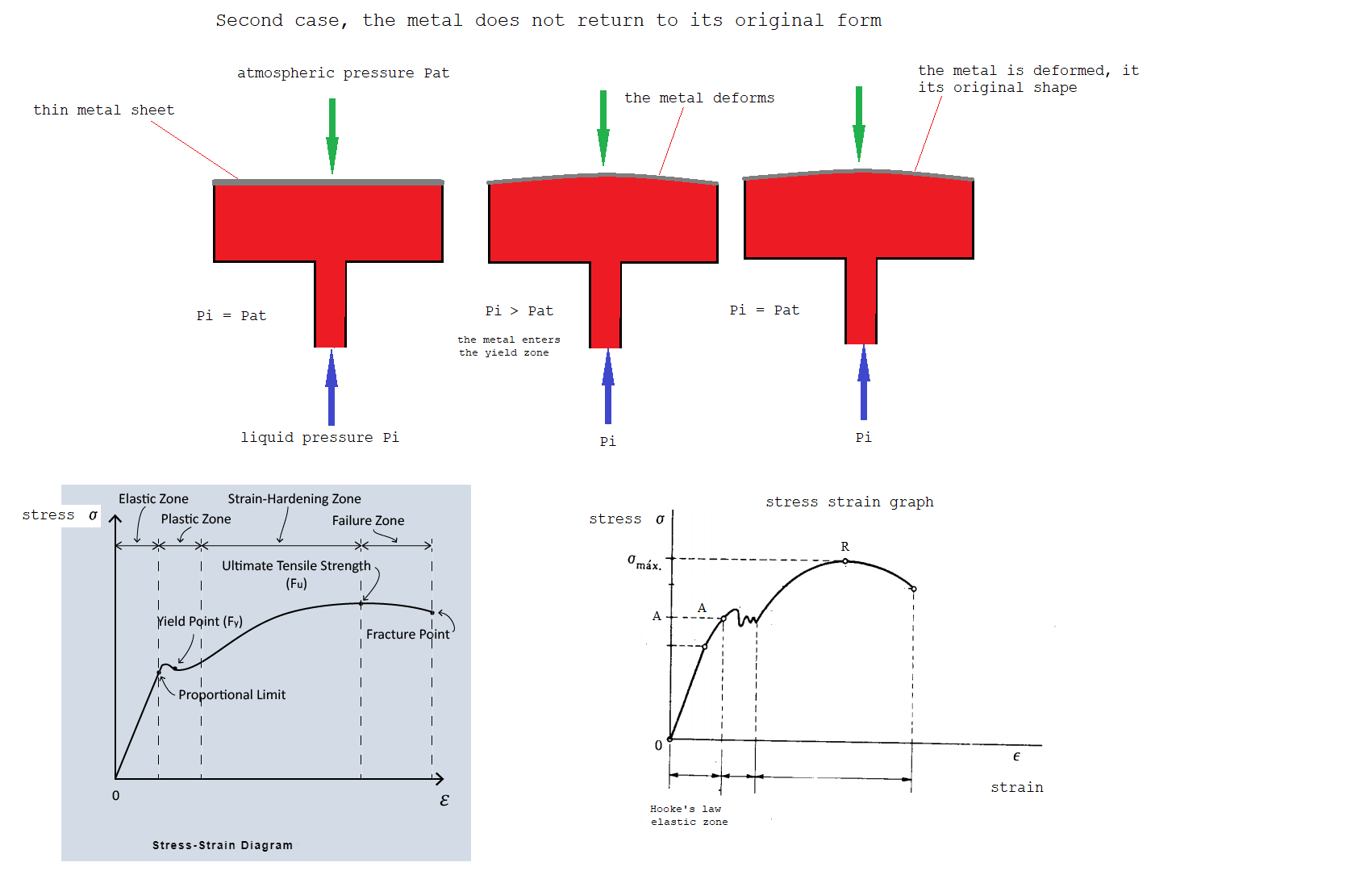

Qualitative deflection of a very thin metal plate under the pressure of a liquid or gas.

Sometimes it can happen that a liquid of a certain pressure, viscosity and temperature, or a gas at a certain pressure enters a container, limited on the outside by a very thin sheet of metal, which would be, for example, subjected on one side to the atmospheric pressure Pat and on the other hand to the pressure of the liquid or gas Pi. In this situation, the metal deforms and two phenomena can occur: when the pressure decreases and the metal has elastic properties, it returns to the original situation, fulfilling Hooke's law, and if for any reason, the metal enters the zone of creep, in this case the metal no longer returns to its original shape, that is, it deforms and if the pressure is very high, the metal could reach the breaking point.

Problem associated with glue and metal foil.

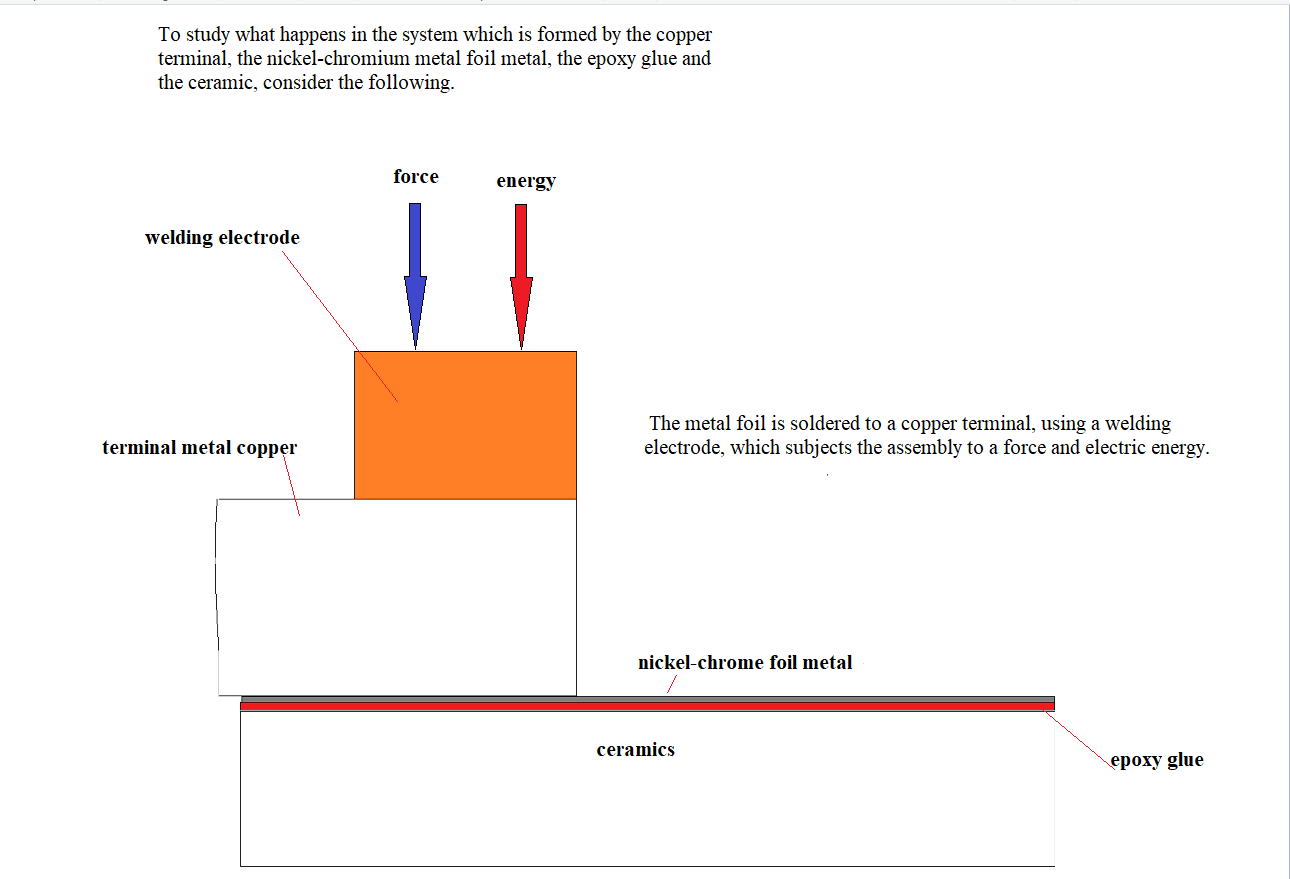

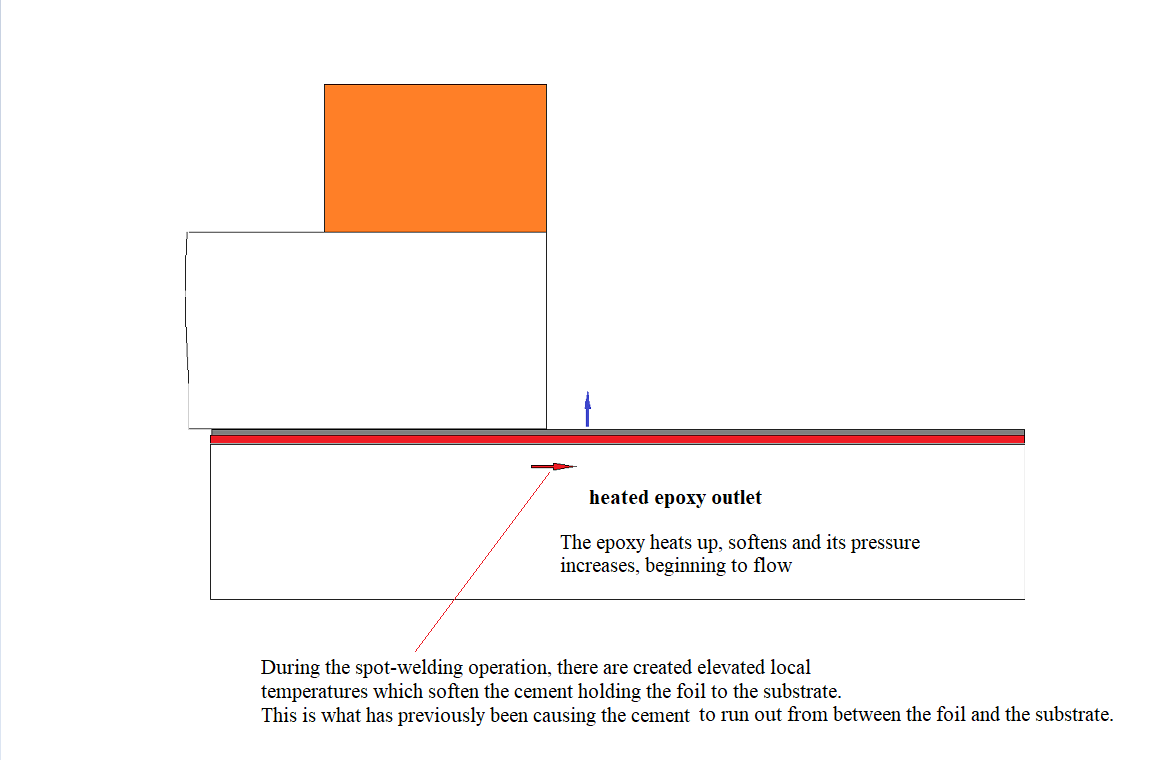

There is a problem associated with this type of construction, having a glue with a temperature at which it begins to soften, because at higher temperatures, the thermal energy of the molecule increases with increasing intermolecular distances, causing the reduction of intermolecular forces and consequently the viscosity decreases, this temperature is in the order of 250 degrees Celsius. Then the metal sheet, to which it is necessary to weld copper terminals, for connection to the external circuit and whose melting temperature is 1200 degrees Celsius, when these two phenomena are combined, a deformation of the metal sheet occurs at the time of welding the terminal, the glue presses on the metal sheet and deforms it and can even break it. The precision resistor has a thin resistive sheet cemented to a much thicker rigid substrate. The foil has formed a pattern on it that defines the resistive path between the terminal pads. Copper wires can be spot welded directly to these pads without damaging the joint. To that end, openings are provided through the end pads, (Kenneth R. Lewis ) through which cement softened, as clarified above, by the heat of spot welding can expand locally and gas evolved under pressure can escape or no.

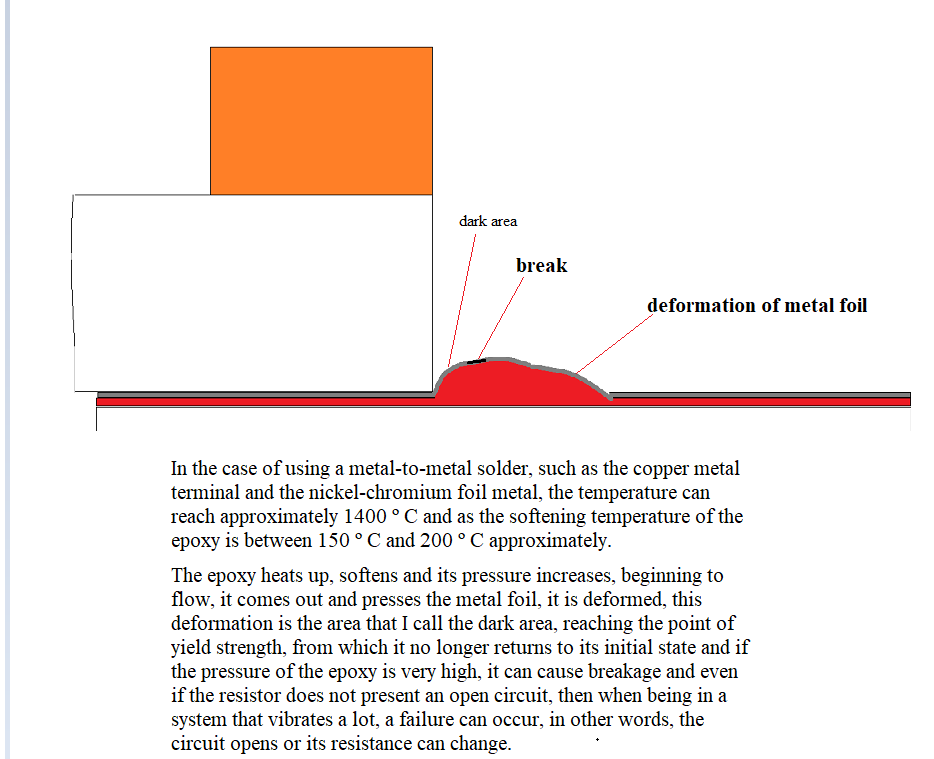

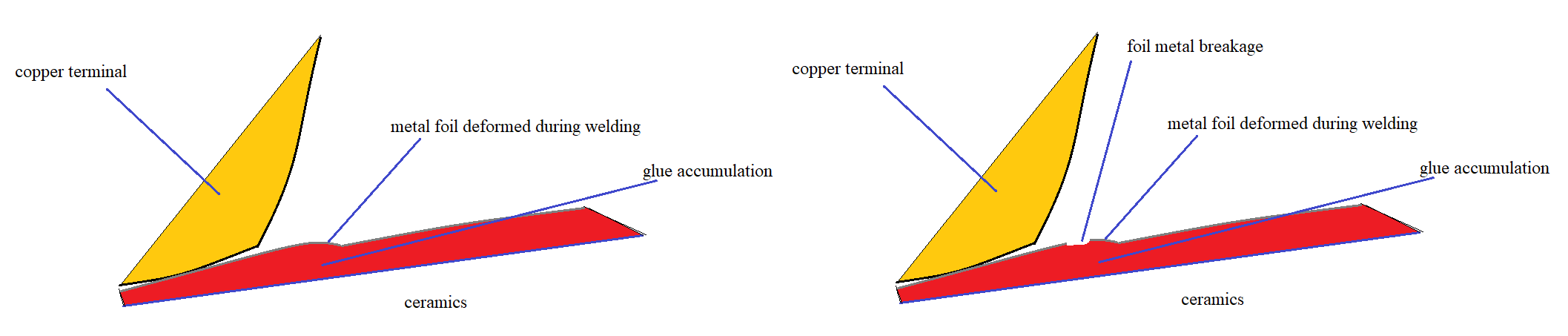

deformation of metal foil

The phenomenon produces the breaking effect of the metal foil during the welding of the copper terminal, in these conditions the entire crystalline structure of the metal undergoes changes that modify what is obtained during the thermal treatment, in the TENSILE STRAIN-STRESS diagram, the point is reached of rupture, the rupture of the drawing can measure between 10 and 40 micrometers wide.

Graphic description of the defect

To avoid the problem represented in the latest drawings, Kenneth R. Lewis,

Attachment of leads to precision resistors, Kenneth R. LewisAnthony C. Meenan

https://patents.google.com/patent/US4286249A/en

"A precision resistor has a thin resistive foil cemented to a much thicker rigid substrate. The foil has formed therein a pattern defining the resistive path between terminal pads. Copper leads can be spot-welded directly to these pads without damage to the junction. To that end, apertures are provided through the terminal pads, through which cement softened by the spot-welding heat can locally expand and gas evolved under pressure can escape, all without adversely affecting the junction and without substantial lifting of the terminal pads from the substrate."

developed in 1981, some windows around the terminal of the metal foil, through which the hot epoxy comes out and this would attenuate the defect, the following drawing is a representation of the phenomenon .

hot epoxy exit windows, developed by Kenneth

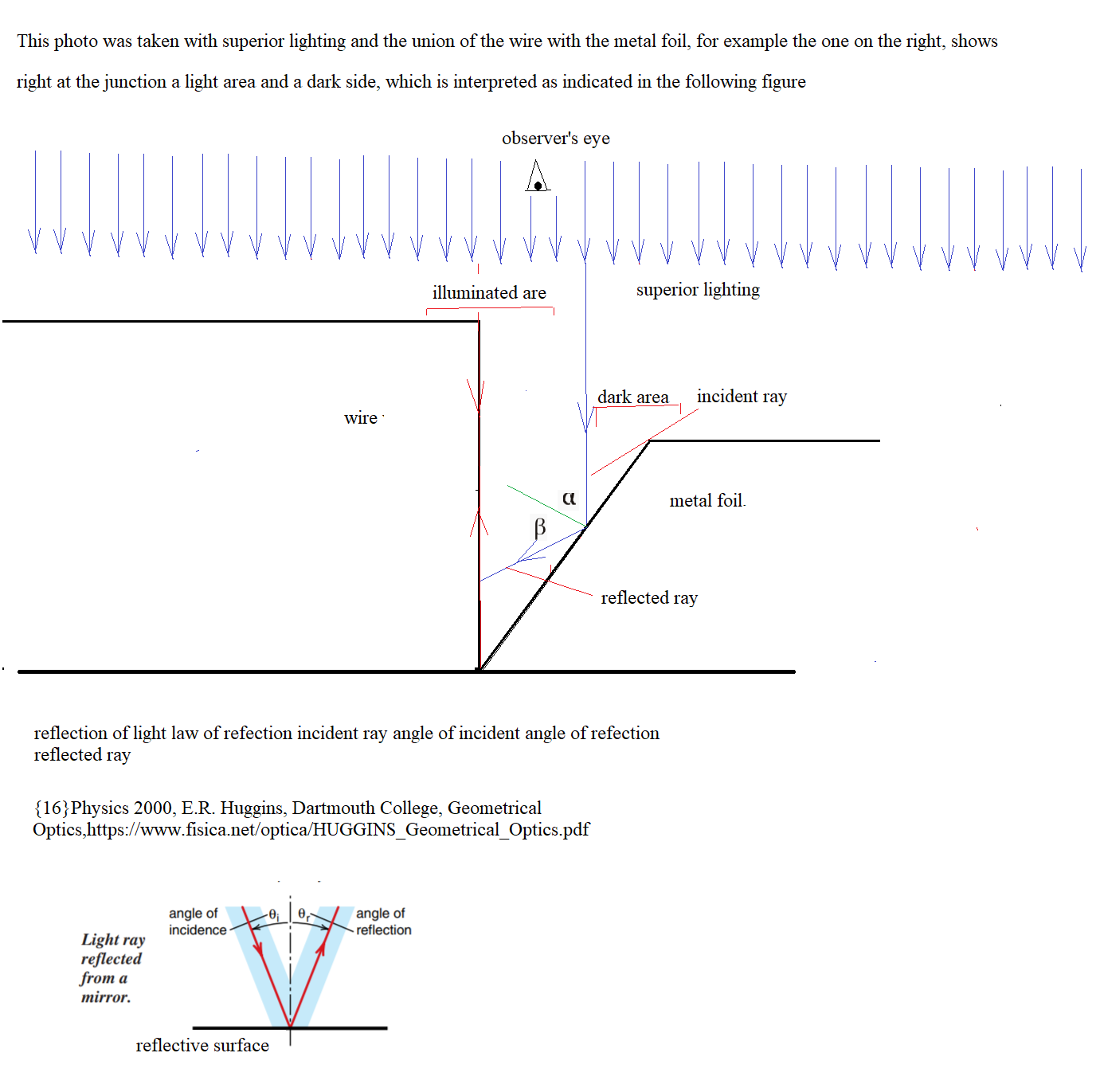

photograph taken of a metal foil resistor, with vertical lighting, with the terminals soldered and where you can see a light area and a dark area in the soldering area, due to the effect of the pressure of the glue on the metal foil, which remains

"VISHAY VAR Z-Foil Audio Resistor"

https://hifiduino.wordpress.com/2013/07/13/vishay-var-z-foil-audio-resistor/

From the following drawing, the reader will be able to understand the effect of vertical illumination and the appearance of a light zone, reflection of the vertical rays and a dark zone due to the oblique reflection due to the elevation of the deformed metal.