Pressure Hole

🛑 👉🏻👉🏻👉🏻 INFORMATION AVAILABLE CLICK HERE👈🏻👈🏻👈🏻

https://www.cambridge.org/.../S0022112084001099a.pdf/pressurehole_problem.pdf

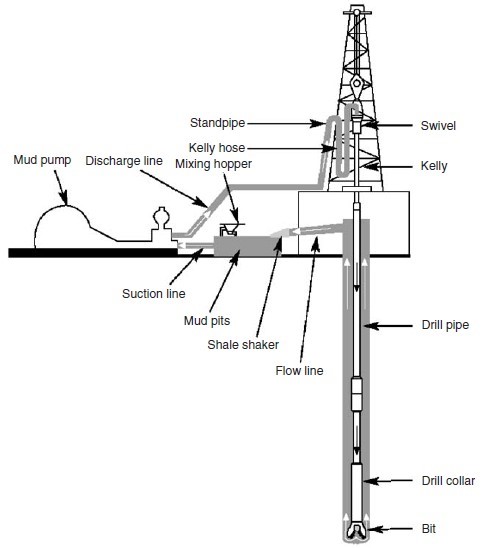

The wall pressure in a flow is usually measured by drilling a hole and connecting it to a manometer. The consequence of the local perturbation generated by a hole of diameter d is that the measured pressure pd is somewhat different from the true pressure …

https://van.physics.illinois.edu/qa/listing.php?id=2248

Перевести · 22.10.2007 · The pressure of the water near the hole is the sum of the air pressure on the top surface of the water and the extra you get from the weight of the water. This pressure …

Casing to Bottom Hole Flowing Pressure Calculation

Putt under pressure | hole putts when it matters

Jack's Water Jack High Pressure Hole Digger Water Auger

HOLE MORE PRESSURE PUTTS - GREAT DRILL

https://www.sciencedirect.com/topics/engineering/borehole-pressure

Перевести · In order to show the difference between the block blasts and the quarry blasts, we compare the pressures from the quarry with those from the blocks, and then we find: (1) The maximum borehole pressure in the 89 mm hole in the quarry is about 9.5 GPa, which is much higher than 2.35 GPa measured in 37 mm hole in the block, indicating that borehole pressure is dependent on charge diameter (both 89 mm and 37 mm holes are fully charged). (2) The pressure in the 37 mm hole …

https://www.trenchlesspedia.com/definition/4529

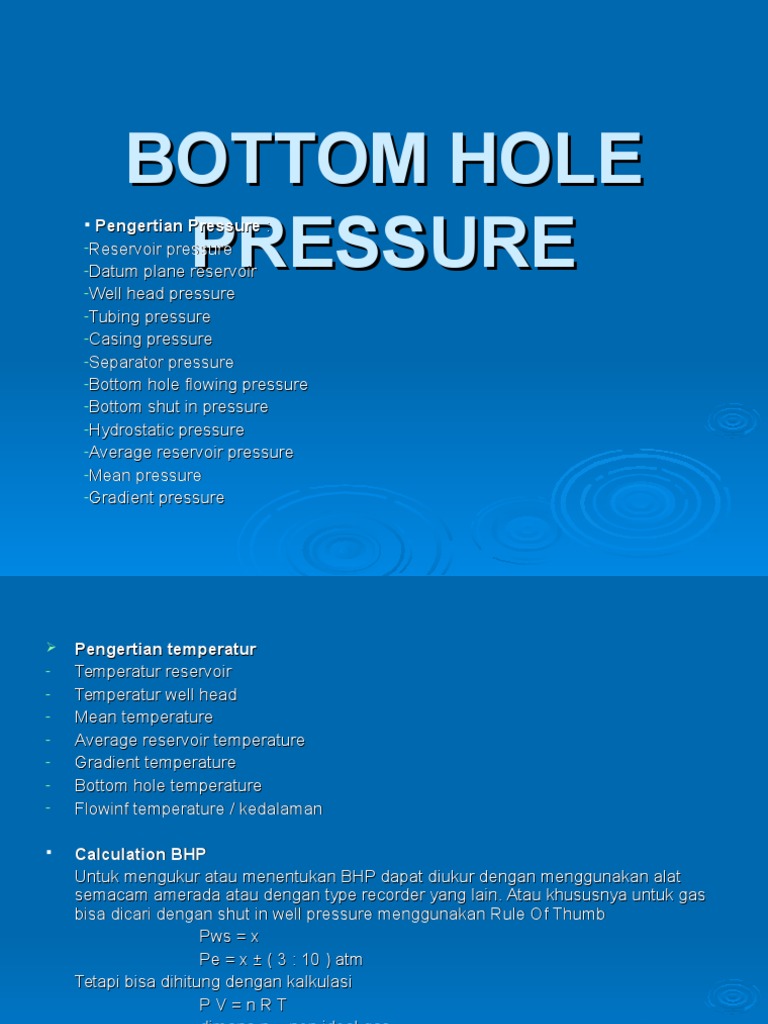

Перевести · 07.12.2019 · Bottomhole pressure (BHP) (or downhole pressure) is the pressure measured at the bottom of the hole in pounds per square inch (psi). It is the sum of the …

https://glossary.oilfield.slb.com/en/terms/b/bottomhole_pressure

Перевести · The pressure, usually measured in pounds per square inch (psi), at the bottom of the hole. This pressure may be calculated in a static, fluid-filled wellbore with the equation: BHP = MW * Depth * 0.052 where . BHP is the bottomhole pressure …

Definition - What does Bottomhole Pressure (BHP) mean? Bottomhole pressure (BHP) (or downhole pressure) is the pressure measured at the bottom of the hole in pounds per square inch (psi). It is the sum of the different pressures acting downhole or at the bottom of the drilled hole.

www.trenchlesspedia.com/definition/4529/…

What is the pressure of a borehole?

What is the pressure of a borehole?

The borehole pressure was measured from a blasthole of 89 mm in diameter in a quarry [6]. The borehole was stemmed by 5 mm gravels and the explosive was Emulsion 682, which was fully charged in the hole. The pressure gauge was placed at the bottom and the detonator at 0.1 m over the gauge. The stemming was 1.7 m long.

www.sciencedirect.com/topics/engineering…

How is the pressure of water near a hole determined?

How is the pressure of water near a hole determined?

The pressure of the water near the hole is the sum of the air pressure on the top surface of the water and the extra you get from the weight of the water. This pressure from the weight of the water is proportional to the depth from the surface of the water.

van.physics.illinois.edu/qa/listing.php?id=2…

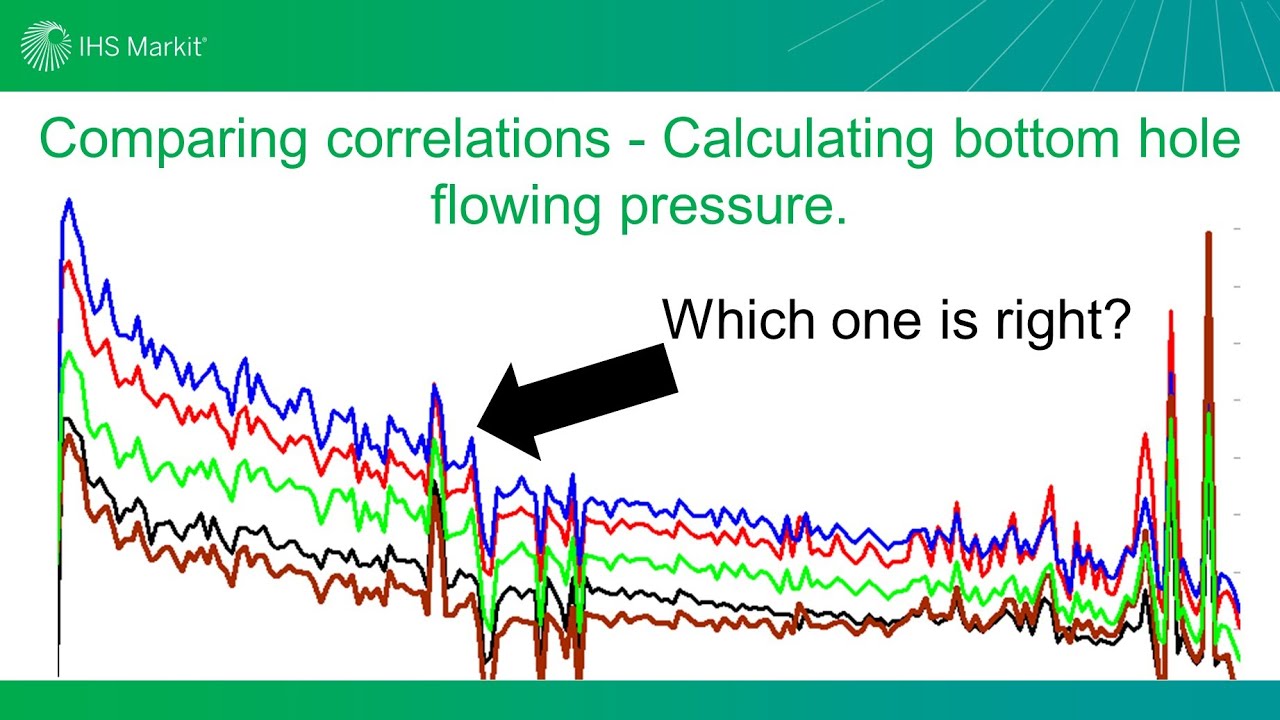

What is the difference between flowing and static bottom hole pressure?

What is the difference between flowing and static bottom hole pressure?

Flowing bottom hole pressure is the pressure measured at the bottom of a well when oil and gas flow are produced. Static bottom hole pressure is the pressure when there is no flow at the well and pressure has reached a stabilized condition. A static condition may be achieved by shutting the well for a considerable period of time.

www.sciencedirect.com/topics/engineering…

https://physics.stackexchange.com/questions/358258/hole-in-a-water-bottle

Перевести · 19.09.2017 · I understand that when you make a hole on a bottle filled with water and put the cap on tight the water will not flow out due to the atmospheric pressure acting on the hole. …

https://en.m.wikipedia.org/wiki/Well_control

Перевести · Bottom hole pressure is used to represent the sum of all the pressures being exerted at the bottom of the hole. The pressure is …

https://www.sciencedirect.com/topics/engineering/reservoir-pressure

Перевести · Flowing bottom hole pressure is the pressure measured at the bottom of a well when oil and gas flow are produced. • Static bottom hole pressure is the pressure when there is no flow at the well and pressure …

https://en.m.wikipedia.org/wiki/Bearing_pressure

Перевести · When the parts are in wood, the acceptable limit pressure is about 4 to 8.5 MP. Plain bearing. In plain bearings, the shaft is usually in contact with a bushing (sleeve …

https://www.mayoclinic.org/diseases-conditions/bed-sores/symptoms-causes/syc-20355893

Перевести · 29.02.2020 · Bedsores — also called pressure ulcers and decubitus ulcers — are injuries to skin and underlying tissue resulting from prolonged pressure on the …

РекламаМайская распродажа! Скидка 73%. Моментальная доставка. Более 85.000 отзывов.

Не удается получить доступ к вашему текущему расположению. Для получения лучших результатов предоставьте Bing доступ к данным о расположении или введите расположение.

Не удается получить доступ к расположению вашего устройства. Для получения лучших результатов введите расположение.

Zong-Xian Zhang, in Rock Fracture and Blasting, 2016

The borehole pressure was measured from a blasthole of 89 mm in diameter in a quarry [6]. The borehole was stemmed by 5 mm gravels and the explosive was Emulsion 682, which was fully charged in the hole. The pressure gauge was placed at the bottom and the detonator at 0.1 m over the gauge. The stemming was 1.7 m long. In order to show the difference between the block blasts and the quarry blasts, we compare the pressures from the quarry with those from the blocks, and then we find: (1) The maximum borehole pressure in the 89 mm hole in the quarry is about 9.5 GPa, which is much higher than 2.35 GPa measured in 37 mm hole in the block, indicating that borehole pressure is dependent on charge diameter (both 89 mm and 37 mm holes are fully charged). (2) The pressure in the 37 mm hole climbs up from the beginning to the peak pressure much more slowly than that in the 89 mm hole. The main reason is that the gauge in the 37 mm hole was placed about 15 to 20 cm over the bottom by an epoxy, which is much softer than the cement used in the 89 mm hole [6]. The epoxy makes the shock pressure damped in the beginning. In contrast, in the quarry blast the gauge was placed 10 cm over the bottom and fixed by cement. (3) Both borehole pressures suddenly drop down to zero from a high pressure at the end of measured pressures. This is because either the gauge or the cable was broken during blasting.

In these blasts, both detonators and gauges were placed at or close to the bottoms of blastholes. Since the gauge position in a blasthole affects the measured borehole pressure, when a gauge is placed over the top of charge, or in the stemming just over the charge, the borehole pressure will be different from that when the gauge is at other places such as the bottom of the borehole.

When a pressure gauge was installed in the stem just over the ANFO explosive in the blasthole with a diameter of 95 mm or 110 mm, the measured results show the following [8]: (1) The maximum borehole pressure measured is greater than 8 GPa. (2) The pressure rapidly goes up from zero to the maximum pressure within just a few microseconds (μs), representing a typical character of shock waves. (3) The duration of the measured borehole pressure is very short. For example, one complete borehole pressure curve measured shows that the duration is about 200 μs, which is much shorter than the pressure measured at the bottom of the blasthole. This is because when the detonation arrives at the gauge at the stem, the detonation in the hole has already completed. In this case, the borehole pressure duration mainly depends on how long time the stem is ejected.

URL: https://www.sciencedirect.com/science/article/pii/B9780128026885000105

Zong-Xian Zhang, in Rock Fracture and Blasting, 2016

The borehole pressure or detonation wave in a blasthole contains most of the explosive energy. The energy carried with the detonation wave is further transferred to the rock in the form of stress waves. In order to make efficient use of the detonation energy, the stress waves from adjacent blastholes should be efficiently superimposed on each other. In this way, a better stress or energy distribution can be made. Since the original stress wave caused by blasting is a P-wave, a compressive wave with a small tensile tail, the efficient stress wave superposition from adjacent holes should be realized in their compressive parts rather than the tensile ones. For example, an efficient superposition should be the one shown in Fig. 16.3b.

All the S-waves, either produced by blasting or reflected from a free surface by a compressive wave, are neglected in this chapter, in order to have a simple analysis. This treatment will influence the result of the determined delay time, but this influence will be limited to a small extent since S-waves are much slower than P-waves. In order to achieve an efficient stress superposition in multihole blasting, the delay time should meet the condition in Eq. 16.7; that is,

As described earlier, a zero or very short delay time will give rise to poor fragmentation, so the delay time chosen should not be very small.

URL: https://www.sciencedirect.com/science/article/pii/B9780128026885000166

Zong-Xian Zhang, in Rock Fracture and Blasting, 2016

This process has been described in detail in the chapter: Single-Hole Blasting. For numerical simulation of rock blasting, however, it is necessary to simplify this process and focus on the key issues, as follows.

Detonation waves or borehole pressures at different positions in the blasthole are generally different from one another, for example in their wave lengths. As shown in Fig. 20.3, one primer is placed at the bottom of a blasthole. When the detonation front arrives at location C, the boundary between the explosive charge and the stemming, the expanded wall of the blasthole, the crushed zone, and the cracked/fractured zone are shown in Fig. 20.3a. If there are three high-pressure gauges installed at three locations A, B, and C in the explosive, and they are triggered at the same time as the primer is initiated, then we will get three detonation waves from the gauges at A, B, and C that are shown by the curves at Fig. 20.3d, c, and b, respectively. In the following we discuss two cases.

Figure 20.3. Diagram of detonation process and borehole pressures at different positions in the blasthole.

(a) Crushed zone, fractured zone, and expanded borehole at the moment when detonation front arrives at C; (b) borehole pressure at C; (c) borehole pressure at B; (d) borehole pressure at A where the primer is placed.

The first case assumes that there are no free surfaces outside the blasthole, either parallel to or inclined to it. In this case the blasting will result in a larger hole or crater in the rock. As a consequence, the pressure gauges at A, B, and C will record three pressure profiles as indicated by the three curves at Fig. 20.3d, c, and b, respectively. The wave length will be the greatest at A, the least at C, and in between at B. Note that the wave length mainly depends on the time during which the detonation products (ie, gases) completely escape out at each of these three locations.

The second case assumes that there is a free surface close to and parallel to the blasthole, and that after blasting, the burden rock is completely fragmented and thrown away. In this case the length of detonation wave mainly depends on (1) the location at the blasthole, (2) the period of time during which gases move out at the location, (3) the period of time during which the burden rock at the location is fragmented and thrown away, and (4) the period of time during which the stemming is wholly ejected. Anyway, in this case the length of the detonation wave at some locations may be almost a constant, but it will be variable at other locations.

The explosive energy that is released during detonation in a blasthole is contained in the shock wave (front), the reaction zone, and the detonation products or gases (rarefaction wave). Furthermore, the energy contained in the detonation products is much more than that in both the shock wave (front) and the reaction zone during or after detonation. Therefore, most of the explosive energy available to rock fracture comes from the detonation products, the gases, or the rarefaction wave. In other words, the energy in the gases has already been accounted for in the detonation wave. This will be explained by means of Fig. 20.4.

Figure 20.4. Diagram of blasting process in a thin part of the cylinder.

(a) Borehole pressure; (b) expanded borehole, grown crushed zone and extended cracks at time tI; (c) grown crushed zone and extended radial cracks at time tII; (d) completely broken plate of the cylinder at time tIII.

Assume that there is a blasthole at the center of a cylinder of rock. We just look at a very thin part of the cylinder at position B in Fig. 20.3. During blasting the detonation wave or borehole pressure in this part of cylinder (ie, a plate) is shown in Fig. 20.4a. When detonation arrives at the plate, the shock wave causes an extremely high pressure, as shown by the peak pressure in the curve of borehole pressure. Following the shock pressure is the reaction zone that is very thin together with the shock. At the end of the reaction zone the chemical reaction is either completed in ideal detonation or partially completed in nonideal detonation. After the chemical reaction is completed, the explosive energy is released and it is contained in the blasthole in the form of a detonation wave. The detonation wave is acting on the walls of the blasthole from the beginning of detonation to the end of borehole failure (disintegrated). For example, Fig. 20.4b indicates that at the time tI when detonation is complete the blasthole has expanded and a crushed zone has appeared. At the same time radial cracks have grown, but all these processes have not completed yet. As the time increases to tII, the blasthole has expanded to a larger size, the crushed zone has grown to a greater range, and radial cracks have become longer and wider, as indicated in Fig. 20.4c. At the same time, the gases move into the cracks and act on their surfaces. As a consequence, expanding borehole, growing crushed zone, and propagating and widening cracks result in a decrease in the borehole pressure. When the time rises to tIII, the blasthole is wholly destroyed and the plate (cylinder) is broken into several pieces, as shown in Fig. 20.4d. At this moment, all the gases contained in the blasthole are released into the air. Correspondingly, the wave pressure acting on all pieces of rock, including the walls of the blasthole, decreases to the atmospheric pressure.

URL: https://www.sciencedirect.com/science/article/pii/B9780128026885000208

The Kirsch equation is commonly used to calculate the stresses around the borehole. The stress level defines the loading on the borehole wall, and the rock strength the resistance to withstand this load. Many papers have been published on this subject; McLean and Addis (1990) and Aadnoy and Chenevert (1987) provide a good overview.

It is well established that the stability of a borehole falls into two major groups:

Borehole fracturing at high borehole pressures. This is in fact a tensile failure, where the consequence may be the loss of circulation. In a pressure control situation, this is a concern, and further drilling may be halted until circulation is reestablished.

Borehole collapse at low borehole pressures. This is a shear failure caused by high hoop stress around the hole, exceeding the strength of the rock. There are many variations of the collapse phenomenon. In some cases, the rock may yield resulting in tight hole. In other cases, a more catastrophic failure occurs resulting in collapse, which again may lead to hole cleaning problems.

Fig. 10.4 illustrates the stresses acting on the borehole wall when the mud pressure is varied. Fig. 10.4A shows the three main stresses acting on the borehole. The radial stress acting on the borehole wall is in fact the pressure exerted by the drilling fluid. The axial stress is equal to the overburden load for a vertical well. However, around the circumference of the hole is the tangential stress acting. This is also called the hoop stress. This stress depends strongly on the borehole pressure. These three stresses can, in their simplest form, be expressed as

Figure 10.4. Borehole stresses with varying mud weight: (A) stresses acting on the borehole wall and (B) borehole stresses as a function of borehole pressure.

where σr is the radial stress (psi), Pw is the wellbore internal pressure (psi), σθ is the tangential (hoop) stress (psi), σa is the average horizontal stress (psi), and σv is the vertical (overburden) stress (psi).

To understand the borehole failure mechanisms in context of the borehole stresses, Fig. 10.4B is developed. The three stress components are plotted as a function of borehole pressure. The vertical stress or the overburden is not affected by the mud weight and remains constant. The radial stress is equal to the borehole pressure and has therefore a unit slope in the diagram. The tangential stress decreases with increased borehole pressure.

At low borehole pressures, the tangential stress is high. Since there is a significant difference between the radial and tangential stress, a considerable shear stress arises. It is this shear stress that ultimately results in borehole collapse. At high borehole pressure, on the other hand, the tangential stress goes into tension. Since rocks are weak in tension, the borehole will fracture at high borehole pressures, usually resulting in an axial fracture. These two failure types are indicated in Fig. 10.4B. More complex failure modes can be evaluated (Maury, 1993), but this will not be pursued here.

From the discussion above, we observe that low and high borehole pressures produce high-stress conditions and bring the hole toward a failure state. By further inspection of Fig. 2.4B, we observe that at a given point the radial and the tangential stresses are equal. Here, the mud weight is equal to the in situ stress, and there will be no abnormal stresses. This will be further discussed in the following section.

URL: https://www.sciencedirect.com/science/article/pii/B9780128159033000108

Zong-Xian Zhang, in Rock Fracture and Blasting, 2016

Which factors affect the amplitude and form of a vibration wave caused by blasting?

According to shock wave theory, a higher velocity of detonation (VOD) causes greater borehole pressure, while a larger blasthole produces higher VOD until the diameter of the blasthole reaches a

High Heels Sound

Free Watch Teens Porn

Daughter Video Free Porn

Sex Couple French Europe

Free Sex Porn Photos

The pressure-hole problem - Cambridge University Press

Q & A: Pressure and holes in cans | Department of Physics ...

Borehole Pressure - an overview | ScienceDirect Topics

What is Bottomhole Pressure (BHP)? - Definition from ...

bottomhole pressure | Oilfield Glossary

Well control - Wikipedia

Reservoir Pressure - an overview | ScienceDirect Topics

Bearing pressure - Wikipedia

Bedsores (pressure ulcers) - Symptoms and causes - Mayo Clin…

Pressure Hole