Polyamide Nylon

⚡ 👉🏻👉🏻👉🏻 INFORMATION AVAILABLE CLICK HERE 👈🏻👈🏻👈🏻

РекламаКапролон, капролактан, капролактам

https://matmatch.com/learn/material/polyamide-nylon

Перевести · Nylon is the commercial name for a type of polyamide thermoplastic. It was first developed by DuPont engineers in the mid-1930s and has since been used in almost every industry. Polyamide nylon …

https://omnexus.specialchem.com/selection-guide/polyamide-pa-nylon

Перевести · Polyamide 11/ PA11/ Nylon 11 is a rare bio-based engineering plastic that is derived from renewable resources (castor plants) and produced by polymerization of 11-amino undecanoic acid. Rilsan® - or polyamide 11 - is one of the first biosourced polymers. Melting point of Polyamide …

Полиамиды — пластмассы на основе линейных синтетических высокомолекулярных …

Текст из Википедии, лицензия CC-BY-SA

https://www.askdifference.com/nylon-vs-polyamide

Перевести · 12.11.2018 · Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides. Nylon …

https://www.bpf.co.uk/plastipedia/polymers/Polyamides.aspx

Перевести · Nylons (Polyamide) The name "nylons" refers to the group of plastics known as 'polyamides'. Nylons are typified by amide groups (CONH) and encompass a range of material types (e.g. Nylon 6,6; Nylon 6,12; Nylon 4,6; Nylon 6; Nylon 12 etc.), providing an extremely broad range of available properties. Nylon …

https://www.differencebetween.com/difference-between-nylon-and-polyamide

Перевести · 03.03.2021 · Nylon and polyamides are two types of polymer materials. The key difference between nylon and polyamide is that nylon is a synthetic material, whereas polyamides can be either natural or synthetic. Moreover, nylon has great resistance against moisture and rain while polyamide …

What ' s The difference between a nylon and a polyamide?

What ' s The difference between a nylon and a polyamide?

VS. The main difference between Nylon and Polyamide is that the Nylon is a family of synthetic polymers originally developed as textile fibers and Polyamide is a macromolecule with repeating units linked by amide bonds. Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides.

www.askdifference.com/nylon-vs-polyamide/

Any of several thermoplastic polyamide plastics, comprising a family of high-strength resilient synthetic materials, used mostly in fibers. A synthetic fabric consisting of fibers of nylon [wn1]. Stockings made of a thin form of nylon {2}, especially full-length stockings either sheer of of varying shades.

www.askdifference.com/nylon-vs-polyamide/

Which is the most common type of polyamide?

Which is the most common type of polyamide?

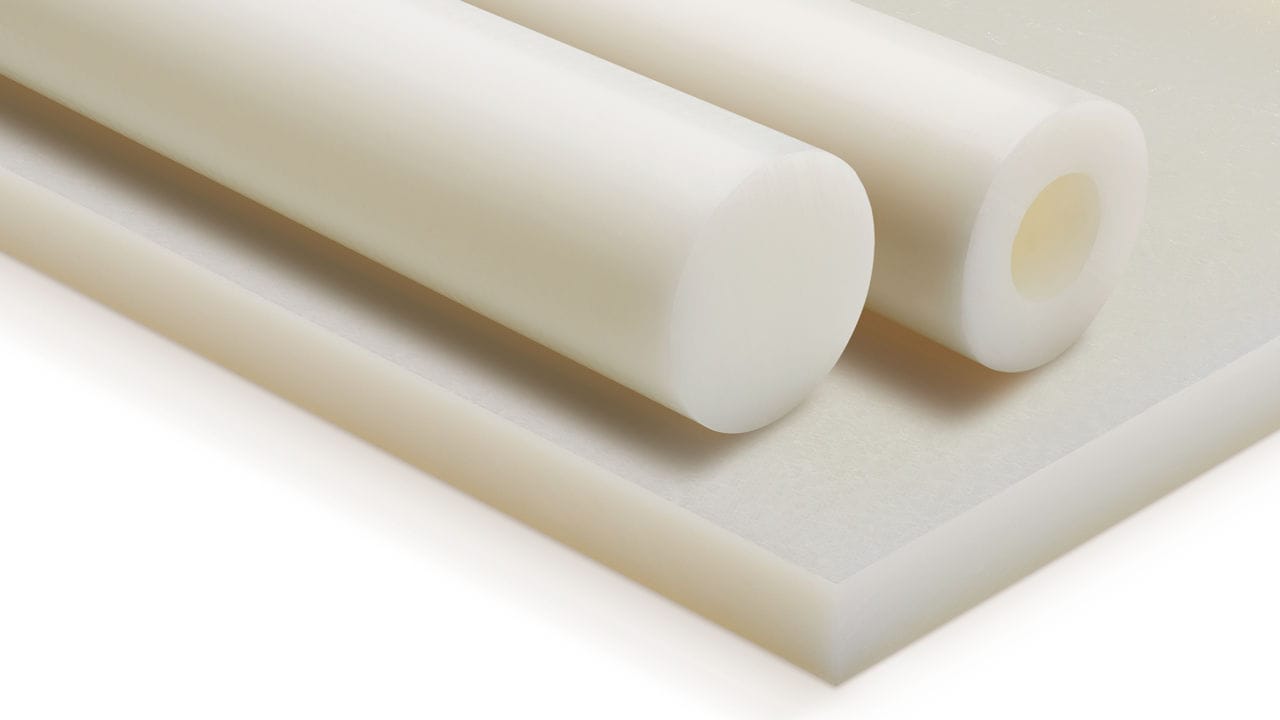

These numbers relate to the molecular structure of the nylon polymer and each structure type will have different properties. The most common polyamide plastics are Nylon 6 extruded, cast PA 6 and Nylon 66 (PA66). Generally speaking, PA Nylon is a semi crystalline thermoplastic with low density and high thermal stability.

www.ensingerplastics.com/en-gb/shapes/en…

In addition, nylon polyamide exhibits very good chemical resistance and is an especially oil resistant plastic.

www.ensingerplastics.com/en-gb/shapes/en…

https://www.ensingerplastics.com/en-gb/shapes/engineering-plastics/pa-polyamide

Перевести · PA material, polyamide or commonly called nylon, is manufactured by Ensinger in standard stock shapes for machining in sheet, rod and tube. There are often numbers associated with nylon plastics types such as 6, 66, 12 and 46. These numbers relate to the molecular structure of the nylon …

https://www.azom.com/article.aspx?ArticleID=442

Перевести · 12.05.2001 · Has lower mould shrinkage than Nylon 6/6 with good fatigue resistance. Useful improvement in stiffness can be obtained by inclusion of glass fibres, unlike acetals. Disadvantages. Highest rate of water absorption and highest equilibrium water content. Lower strength & stiffness than Nylon …

Polyamide || Nylon 6 and Nylon 6,6 || Some important Polymers || UG PaathShaala #polyamide #nylon

Base textile materials: Polyamide (Nylon)

Durch Polykondensation zum Polyamid: Nylon

YouTube › Dr Arti Jain Chemistry classes

https://kirste.userpage.fu-berlin.de/chemistry/kunststoffe/amid.htm

Перевести · Polyamid - Nylon. Polyamide sind Makromoleküle, bei denen die Monomere durch Amidbindungen bzw. Peptidbindungen miteinander verknüpft sind. Natürliche Polyamide sind Peptide und Proteine, z.B. Haare, Wolle, Seide und Eiweiß. Synthetisch hergestellte, langkettige aliphatische Polyamide werden auch Nylon …

РекламаАптека "Aptstore". Поиск и заказ лекарств с доставкой в ближайшую аптеку. · Москва · 152943 · пн-пт 10:00-18:00

Есть противопоказания. Посоветуйтесь с врачом.

РекламаПолиамид 6-ти блочный ПА6 изготовленный литиевым способом. Большой выбор размеров!

Продавец: ООО "Лентехпласт". Адрес: Россия, Санкт-Петербург, Краснопутиловская улица, 69. ОГРН: 1177847053229

Saint Petersburg, Saint Petersburg City

Saint Petersburg, Saint Petersburg City

Не удается получить доступ к вашему текущему расположению. Для получения лучших результатов предоставьте Bing доступ к данным о расположении или введите расположение.

Не удается получить доступ к расположению вашего устройства. Для получения лучших результатов введите расположение.

DSC Practical Interpretation with Examples for Polymer Development

Biodegradable and Compostable Packaging: Getting your Compliance Process Simplified

Achieving High Barrier Performance in Coextruded Films

TORELINA™ Polyphenylene Sulfide Engineering Polymers

Exhibiting high temperature and electrical resistances, polyamides (nylon) are considered as high performance plastics and are widely used in automotive & transportation markets, consumer goods and electrical and electronics applications among others.

Learn more about this interesting class of plastics along with the main applications and benefits of some common polyamides: PA11, PA12, PA46, PA6, PA66 and PPA (polyphthalamides). Explore more about their key properties like mechanical, thermal, electrical, etc., conditions to process this polymer and understand what makes Polyamides an ideal choice in high-end engineering applications.

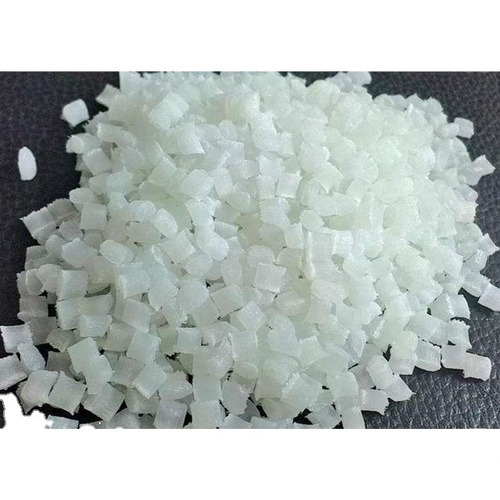

Polyamides or Nylon is the major engineering and high performance thermoplastics class because of its good balance of properties. Polyamides contain repeating amide linkages i.e. –CO-NH–. It is formed by condensing identical units, copolymers for different units.

Polyamides (or Nylon) are made from polycondensation of diacid with a diamine or by ring-opening polymerization of lactams with 6, 11 or 12 carbon atoms.

Hexamethylene Diamine/ Azelaic Acid

Hexamethylene Diamine/ 1,12-Dodecanedioic Acid

Hexamethylene Diamine/ Sebacic Acid

1,12-Dodecanediamine/ 1,12-Dodecanedioic Acid

Aliphtaic Polyamide Polymers and Their Monomers

Molecular Structures of Polyamide 6 and Polyamide 66

PA6 & PA66 are by far the most used Polyamides globally

PA6, PA66 Replace Metal in Automotive Applications

Thanks to their good processability, PA6 and PA66 are often used as an alternative to metal in automotive under the hood parts where design flexibility as well as temperature and chemical resistance are critical.

They ultimately contribute to weight savings, which offers CO2 emissions reduction opportunities. PA66's mechanical properties (stiffness, creep resistance, etc.) help improve safety and comfort in cars.

» View Commercial PA6 Grades for Automotive

Electrical & Electronics Applications - Flame Retarded PA Works Well!

In the electrical and electronic applications, Polyamides 6 and 66 grades are good candidates where specific tests (GWIT, UL94) need to be passed. PA6 & PA66 can easily be flame retarded and halogenated & non-halogenated FR solutions are commercially available.

» See Flame Retardant PA66 Grades Available Today!

Moreover, they also bring solutions in this industry where miniaturization reinforces the needs for high temperature resistance and thin designs (possible due to easy processability).

Good Surface Aspect in Consumer Applications

Polyamide 66 offers solutions for durable Consumer and Industrial Goods, thanks to its easy moldability, colorability, good surface aspect and excellent mechanical resistance.

PA66 is an excellent material when complex designs are needed, and it is also a cost efficient solution.

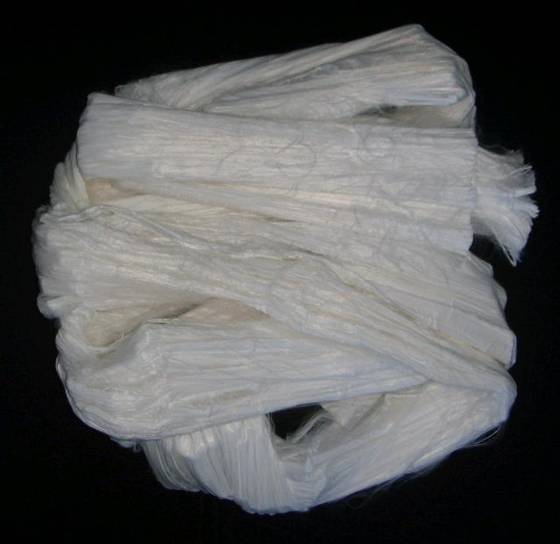

PA6 and PA66 offer very high puncture resistance, barrier resistance to oxygen, carbon dioxide and aromas, transparency, etc. All these properties make PA6, PA66 ideal for use in food packaging (mono or multi-layer).

» Get Access to PA6 Grades Available for Packaging Applications

In the medical field, PA6 is fabricated into tough, puncture-resistant packages for medical blister packs.

PA Replaces PP in Furniture Applications

For the furniture market, PA6, PA66 is used to manufacture stadium seats thanks to their brilliant surface quality, excellent resistance to dirt and aging and offering a great alternative to polypropylene.

The exceptional fatigue properties and high impact and mechanical strength of PA6 and PA66 contribute in sports applications where they are used to manufacture Ski bindings.

The lowest water absorption of all commercially available polyamides

High cost relative to other polyamides

Outstanding impact strength, even at temperatures well below the freezing point

Lower stiffness and heat resistance than other polyamides

Resistant to chemicals, particularly against greases, fuels, common solvents and salt solutions

Poor resistance to boiling water and UV

Outstanding resistance to stress cracking, aging and abrasions

Proper drying before processing is needed

Attacked by strong mineral acids and acetic acid, and are dissolved by phenols

Noise and vibration damping properties

Electrical properties highly depend on moisture content

Fatigue resistant under high frequency cyclical loading condition

Ability to accept high loading of fillers

Highly resistant to ionization radiation

Molecular Structure of Polyamide 12

Lowest water absorption of all commercially available polyamides

Outstanding impact strength, even at very low temperatures

Lower stiffness and heat resistance than other polyamides

Good chemical resistance, in particularly against greases, fuels, common solvents and salt solutions

Outstanding resistance to stress cracking

Proper drying before processing is needed

Electrical properties highly depend on moisture content

Noise and vibration damping properties

Good fatigue resistance under high frequency cyclical loading condition

Good Mechanical

Properties

Particularly at high

temperatures

Outstanding stiffness, fatigue and creep resistance, up to 220°C

High water absorption and water equilibrium content

Excellent abrasion and friction behavior

High temperature processing, due to its high melting point

Very good flow for easy processing

Very low injection cycle time, due to its high crystallization rate

Attacked by strong mineral acids and absorbs polar solvents

Proper drying before processing is needed

Darkens with exposure to high heat

Good electrical insulating properties

High resistance against high energy radiation (gamma and X-rays)

Very high stiffness and strength, compared to PA66

Requires high processing temperatures (up to 350°C)

Attacked by powerful oxidants, mineral acids, acetic acid and formic acid

Thermoplastic Polymers commonly known as Polyamides

First Nylon was produced by Wallace Carothers in 1935

First polyester fiber called Terylene created in 1941

Nylon is formed by the condensation of copolymers. Equal parts of dicarboxylic acid and diamine are used for the process. There are peptide bonds on the ends of the monomers

Synthetic polyesters are made up of dimethyl ester dimethyl terephthalate (DMT) or the purified terephthalic acid (PTA).

Used in apparel, flooring, molded parts for cars, electrical equipment, etc., packaging films

Used to manufacture a variety of products, including textiles, belts, furniture, insulation, padding, tarps and glossy finishes for hardwoods

Exceptionally strong, abrasion resistant, resistant to damage from oil and many chemicals

Strong, resistant to stretching and shrinking, resistant to most chemicals, crisp and resilient wet or dry, abrasion resistant

Low moisture absorbency allows fabric to stretch

No water absorbance, faster drying, wrinkle resistant

Polyamide polymer can be chemically recycled or de-polymerized

Receive weekly digests on hot topics

Want to comment? Please, simply login or register.

We are making a wide industry anonymous research on R&D with chemicals. Please help us by answering the question below:

Is your current visit related to an active project?

No project (self-education, curiosity…)

Yes, I am scanning potential solutions and suppliers

Yes, I am shortlisting the best solutions and suppliers

Yes, I am in a later project phase (sampling, lab test, procurement…)

Nurse Sex Hd

Licking Pussy Man Photo

Pussy Lick Mistress Hd

Best Mouth Fuck

Mudr 10 Free Porn

Polyamide Nylon: Properties, Production and Applications ...

Polyamide/Nylon (PA Plastic): Uses & Properties [Updated 20…

Nylon vs. Polyamide - What's the difference? | Ask Difference

Nylons (Polyamide) - British Plastics Federation

Difference Between Nylon and Polyamide | Compare the ...

PA Polyamide Nylon - TECAMID | Ensinger

Polyamide 6 - Nylon 6 - PA 6

Polyamid - Nylon - Freie Universität

Polyamide Nylon