Overcoming Obstacles: Gains of Injection Moulding Processes

In the current fast-paced manufacturing landscape, businesses are continuously seeking innovative solutions to enhance production while ensuring superior quality and efficiency. A technique that has stood the test of time and continues to evolve is the practice of injection molding. This versatile process offers a myriad of benefits that can address the challenges faced by various industries, from car production to consumer goods. As businesses look to boost their production capabilities, understanding the benefits of injection molding services becomes essential.

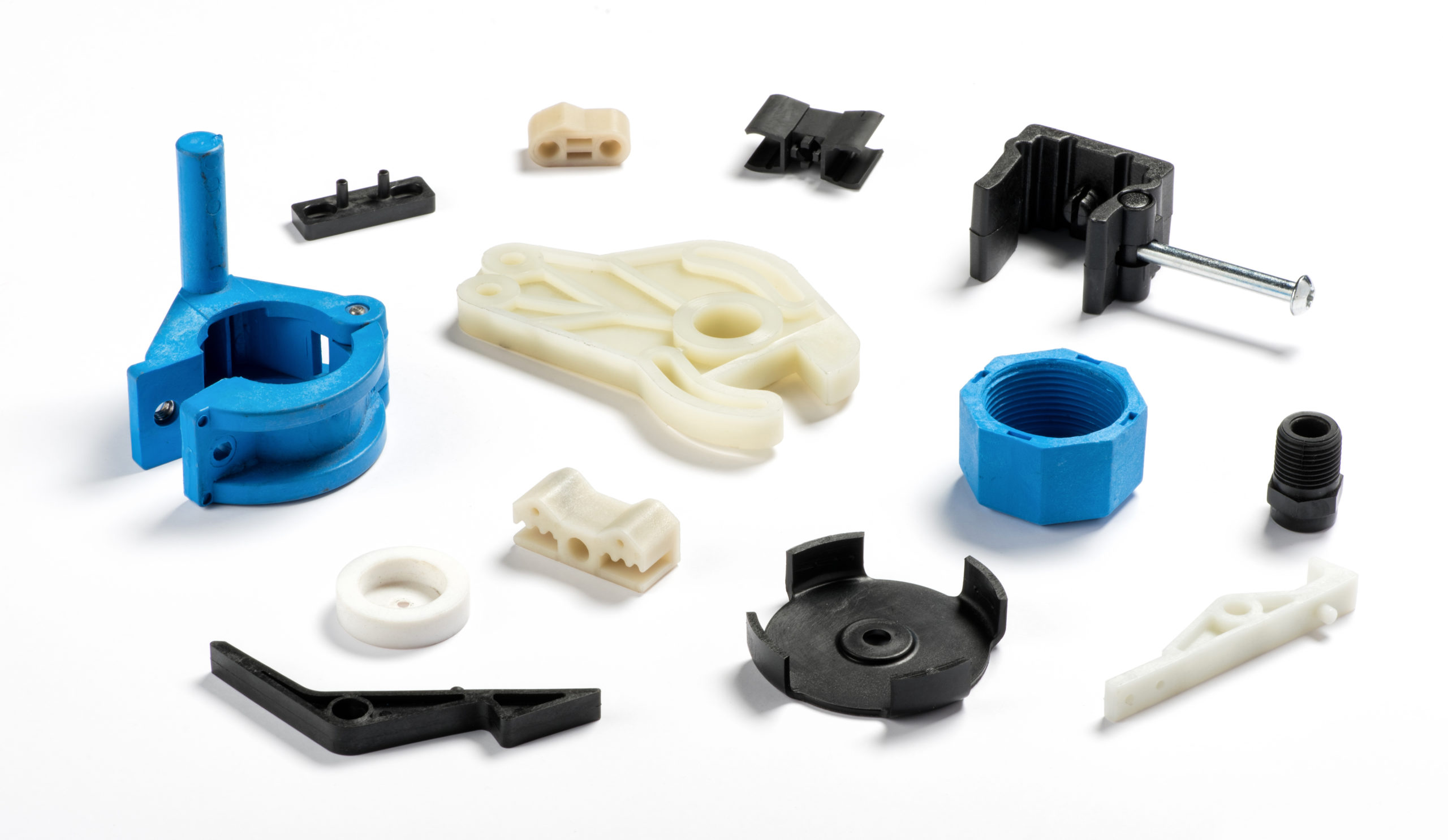

Injection molding is not just about producing high volumes of parts; it is a calculated approach to manufacturing that optimizes both cost and time. By allowing for accurate control over material distribution and minimizing waste, it paves the way for creating intricate designs that meet specific customer demands. The capability to produce detailed shapes with uniformity positions injection molding as unique and establishes it as a key player in current manufacturing solutions. As we delve further into the merits of injection molding, it becomes clear why many organizations are resorting to this technology to resolve their production obstacles.

Grasping Injectable Forming

Injectable forming is a production process utilized to fabricate parts by forcing molten material into a mold. This technique allows for the mass production of synthetic components with high precision and repeatability. It is commonly utilized in multiple industries, including vehicles, retail goods, and medical devices. The process starts with warming the plastic pellets until they become liquid, after that the liquid is injected into a mold cavity. Once solidified, the material hardened, taking the form of the mold.

One of the key advantages of injection molding is its ability to manufacture sophisticated shapes with intricate details. Unlike other manufacturing methods, injection molding can fabricate parts that are not only light but also feature tight tolerances. This capability enables designers and engineers to innovate without being restricted by production limitations. As a result, products can be made more optimally, meeting the increased demands of today's market.

Additionally, injection molding services can significantly reduce waste and lower production costs. The process is designed for maximum efficiency, with minimal excess material and energy consumption. This environmental aspect appeals to many companies looking to enhance their environmental responsibility. By embracing injection molding solutions, businesses can improve their production processes while ensuring superior outputs that meet varied consumer needs.

Advantages of Injection Molding Solutions

Molding services offer significant advantages in manufacturing that can greatly enhance production efficiency. One of the primary benefits is the ability to produce intricate shapes and intricate designs with elevated precision. This method allows for the creation of parts that would be challenging or hard to achieve through other manufacturing methods, ensuring that products meet exact requirements and performance standards.

Another key advantage lies in the scalability of injection molding services. Once a mold is created, the production process can easily be scaled up to meet increasing needs without a corresponding rise in manufacturing costs per unit. This efficiency enables companies to adapt quickly to market changes and consumer needs, making injection molding an ideal choice for both tiny and large production quantities.

Additionally, injection molding is known for its material selection versatility. A variety of thermoplastics and thermosetting polymers can be used in the injection molding technique, allowing businesses to choose materials that best meet their product requirements. This capability not only supports the production of lightweight and durable components but also enables designers to innovate with new materials and enhanced features, ultimately leading to improved item performance and customer satisfaction.

Common Uses and Sectors

Injection molding services are commonly utilized throughout different fields because of their productivity as well as versatility. The auto industry is a major stakeholders of molded parts. From interior components to structural parts, manufacturers rely on this method to produce light and durable components that meet specific requirements. The capability to fashion intricate designs with a high extent of uniformity makes injection molding an ideal option for vehicle applications.

Another significant industry taking advantage from this process is the consumer goods sector. Products ranging from playthings to kitchen utensils are often produced using this technology. The technique allows for the bulk creation of products with uniform quality, which is essential for maintaining brand image and customer happiness. Additionally, the broad range of resources available for molding, including multiple polymeric materials, enables creators to choose characteristics that best fit each product's needs.

The medical sector also witnesses extensive use of molding applications. Medical devices and components often call for significant amounts of accuracy and clean manufacturing standards. Injection molding fulfills these standards, enabling the production of detailed components such as injection devices, medical implants, and medical tools. With the constant improvements in substances and techniques, the clinical industry keeps to capitalize on injection molding for innovative healthcare products that require dependability and protection.