Our Laser engraving - operating principle and benefits - TRUMPF Ideas

Make It Your Own: Why I Laser Engraved My Camera - PetaPixel

Make It Your Own: Why I Laser Engraved My Camera - PetaPixelLaser Magic: Custom Laser Engraving & Etching Services in - The Facts

Often the laser is stationary and the workpiece moves. In some cases the workpiece moves in one axis and the laser in the other. [] A 2nd genre is for cylindrical workpieces (or flat workpieces mounted around a cylinder) where the laser effectively traverses a great helix while onoff laser pulsing produces the desired raster image.

Laser engravers utilizing this technology can work in either raster or vector mode. https://www.youtube.com/channel/UC0rU5swV17mH36Q_Jef98lQ where the laser beam touches the surface area need to be on the focal aircraft of the laser's optical system and is generally synonymous with its focal point. This point is usually small, perhaps less than a portion of [] a millimetre (depending upon the optical wavelength).

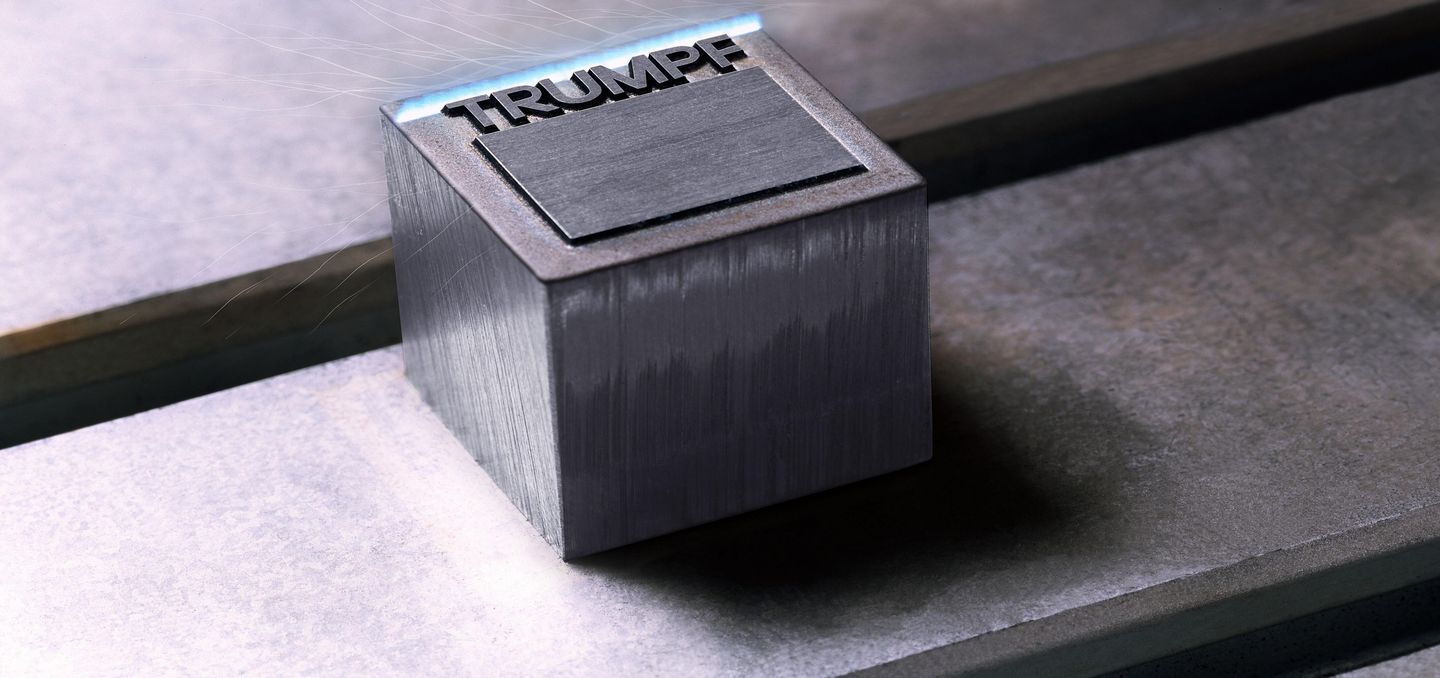

The energy provided by the laser changes the surface of the material at the centerpiece. It might heat up the surface area and subsequently vaporize the material, or maybe the product may fracture (understood as "glassing" or "glassing up") and exfoliate the surface. Cutting through the paint of a metal part is typically how material is laser etched.

Laser Engraving Transparent Materials with CNC Lasers

Laser Engraving Transparent Materials with CNC LasersA laser can get rid of product extremely efficiently because the laser beam can be designed to provide energy to the surface in a way which converts a high portion of the light energy into heat. The beam is highly focused and collimatedin many non-reflective materials like wood, plastics and enamel surfaces, the conversion of light energy to heat is more than x% [] effective. [] However, since of this efficiency, the equipment utilized in laser inscription might warm up rather rapidly.

Exact Scale Images for Laser Engraving : 4 Steps (with Pictures) - Instructables

Exact Scale Images for Laser Engraving : 4 Steps (with Pictures) - InstructablesAbout Laser Engraving Services - CK Fight Life

Alternatively, the laser beam might be pulsed to reduce the quantity of excessive heating. Different patterns can be inscribed by setting the controller to pass through a particular course for the laser beam with time. The trace of the laser beam is thoroughly managed to attain a consistent elimination depth of product.

The speed at which the beam crosses the product is likewise considered in producing etching patterns. Altering the strength and spread of the beam enables more flexibility in the style. For example, by altering the proportion of time (called "duty-cycle") the laser is turned on during each pulse, the power delivered to the engraving surface area can be controlled properly for the product.