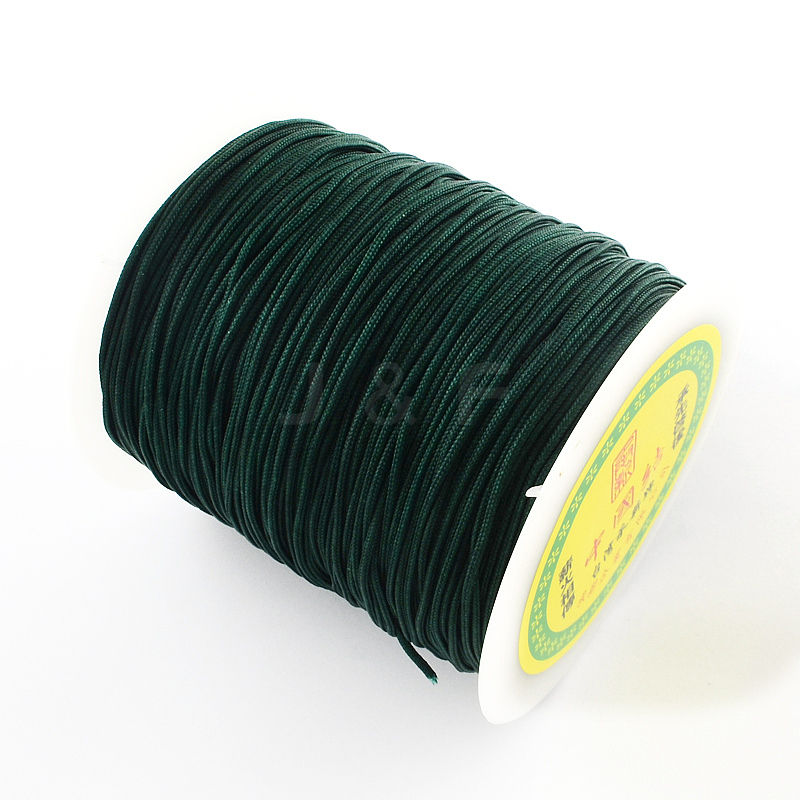

Nylon Thread

💣 👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

U-Jin Joshua Cheah, ... Hongliang Ren, in Flexible Robotics in Medicine, 2020

The rotational motion of the flexible tip was achieved via the setup depicted in Fig. 13.15.

Figure 13.15. Setup illustrating the rotational mechanism of a flexible tip.

As can be seen in Fig. 13.15, the anticlockwise rotation of the axle attached to the stepper motor will cause the shortening of one arm of the nylon thread and the lengthening of the opposite arm, which has been looped around the setup, resulting in the subsequent bending of the flexible tip toward the direction of the shortened nylon thread. In this way, a single stepper motor can fully control the bending motion of the flexible tip in a single plane, and two stepper motors will generate bending motion in a roughly hemispherical working space. Nylon threads were threaded through the holes in the vase-spine design and through the connector tube and were coiled around the motor axles. These threads were used to control the bending motion of the endoscope.

URL: https://www.sciencedirect.com/science/article/pii/B9780128175958000146

Liting Pang, ... Hongliang Ren, in Flexible Robotics in Medicine, 2020

We presented the design of EndoGoose, a transluminal steerable biopsy forceps for minimally invasive procedures. The bending segment consists of a gooseneck, connector beads, connecting springs, nylon threads, and silk threads. The effectiveness of the EndoGoose is determined by the performance of the various components. Functionality tests include the actual maximum bending angle, size of biopsy samples obtained, and steerability of the actively bending section. Tensile and fatigue tests include the maximum tensile stress the cables are able to withstand and bending stress of the gooseneck tube. The prototype has only been used for proof of concept and the demonstration of how the prototype should be able to work and should only be used as a rough gauge of EndoGoose’s performance.

For future work, adding a sensor in the bending segment to state how much the forceps have bent, in order to gauge if forceps approach the maximum angle or has reached the maximum angle and to automatically stop the stepper motors from applying more tension on the guiding cables. An ejection mechanism for the forceps is desirable when forceps are withdrawn, as the tissue samples are ejected upon the release of the knob on the handheld prototype. The size of the biopsy sample can be verified by using animal flesh so that the consistency of the flesh being removed is close to that of a human’s tissue. The depth at which the flesh is being placed should be equivalent to the depth of the tissue of interest in the lumenal cavity. An endoscope has to be used to search for the tissue, and time should be recorded when forceps are inserted into the endoscope to the time when the tissue is withdrawn through the endoscope.

URL: https://www.sciencedirect.com/science/article/pii/B9780128175958000195

A. Mukhopadhyay, V.K. Midha, in Joining Textiles, 2013

Advice is given on seam construction and the selection of nylon and polyester-fibre sewing threads for garments required to meet flammability regulations, particularly the US children’s sleepwear standard DOC FF3-71 (J. & P. Coats Ltd., 1980). To achieve a flare-free seam, it is necessary to use a polyester–fibre or nylon thread in a garment made of thermoplastic fibres, or a cotton thread in a cotton fabric of low flame retardance. Seams consisting of sewing threads made from 100% polyester fibre or 100% nylon will melt but will not be responsible for conveying a flame up a seam unless treated or coated with highly flammable additives. From the flammability viewpoint, blended-fibre threads, e.g. polyester-fibre/cotton core spun threads, are quite flammable and should not be used where the flammability of the end-product is the major consideration.

Jakes et al. (1975) observed that, with flame-retardant thermoplastic fabrics (polyester–fibre and polyester–fibre/acetate), the char length of cotton and core spun thread seams increases proportionately with increasing MR (ratio of thread mass to fabric mass), whereas polyester fibre thread seams are insensitive to MR. For a flame-retardant cotton fabric, the seam char length increases with MR for certain seam types with all threads tested. The flammability of sewing threads must be considered in the context of the end-product utilizing them and not of the threads themselves. in the manufacture of flame-retardant garments, needle coolants and thread lubricants should not be used, since they increase the flammability of the seam (Taylor, 1990).

URL: https://www.sciencedirect.com/science/article/pii/B9781845696276500068

Few fabrics were damaged seriously by needle heat prior to the 1940s. Since then fabrics and sewing threads manufactured from thermoplastic fibres have become common, and the maximum stitching speed of sewing machines has increased markedly from around 1000 to 6000 stitches/min. Thermoplastic sewing threads, such as nylon and polyester, may be heated by the needle, soften, melt, and break. Nylon and polyester threads melt at 240–260 °C. Cotton and silk are not thermoplastic, but degrade at around 400 °C. Thread breaks decrease production levels because of discontinuity in stitching, assuming that the partly-formed seam is not unpicked and fully restitched (Laing and Webster, 1998).

Softened polymer from either the sewing thread or the fabric being stitched (or both) may be deposited in the needle eye. The needle eye cools when machining stops, and the polymer hardens, thus clogging the eye. On restarting the machine, the sewing thread cannot move though the eye and so breaks. During the down stroke part of the stitch formation cycle a crease may form in the sewing thread at the needle eye. If the needle temperature is sufficiently high, this crease may be set in the thread by heating followed by rapid cooling. Any loop subsequently formed in the sewing thread (required during formation of ISO 301 for example), is improperly shaped when the thread is creased and the rotary hook may not enter the loop. This would result in missed or skipped stitches and seam performance is adversely affected. More generally, any thermal damage to the fabric may affect the properties, performance or appearance of a seam. Table 16.7 summarises the causes and solutions for thermal damage (Carr and Latham, 1994, 2000).

Table 16.7. Causes and solutions for thermal damage

Select sharper set or finer ball point

Increase softener content on fabric

URL: https://www.sciencedirect.com/science/article/pii/B9780857090270500163

S. Hayes, J. Mcloughlin, in Joining Textiles, 2013

A number of synthetic fibres are used for sewing thread and can improve the performance of a product in certain specific applications. Polyester, for example, exhibits 100% greater seam strength than cotton thread of the same size. Both polyester and nylon are more resistant to abrasion and chemical degradation than cotton or silk. Nylon threads exhibits good resistance to alkalis but poor resistance to acids; conversely, polyester exhibits good resistance to acids and relatively poor resistance to alkalis. PPTA (poly p-phenylene terephthalamide) sewing thread retains strength at high temperatures. it is thus ideal for applications where such properties are critical, for example, flame resistant furnishings. Polypropylene can be used under different weather conditions, as the presence of moisture results in an average 8% increase in strength and a decrease in elongation resulting from a plasticising effect.

Fibre finishes include glazing, waxing and treating threads with silicone. Each of these treatments is designed to facilitate movement of the thread in the machine, enhancement of thread tenacity, and to protect the needle thread from the high needle temperatures that can be generated at higher sewing speeds (up to 300 °C) to which natural fibres are insensitive. Textured thread is made from continuous filaments of polyester or nylon using a variety of techniques. Air-texturing is a mechanical process in which filaments are passed between a pair of rollers through an air jet, with the first pair of rollers set at a faster speed than the second, thus leading to length overfeed. The air jet blows the filaments apart, forming loops at random points both within, and on the surface of, the filament. Heat treatment sets the loop structure. The final stability of the sewing thread structure is the result of a combination of loop entanglement, twisting and heat-setting. Air-textured threads exhibit high elongation appropriate for the seaming of kitted garments and swimwear where seams are overlocked and covered. Stitch stability is excellent, making it suitable for shoe in-seaming. Air-textured threads are used for purposes such as seaming of flags to heavy denim jeans.

URL: https://www.sciencedirect.com/science/article/pii/B9781845696276500032

Lace is a fabric that is formed as a light netting or other network of threads, with patterns made in the body of the network fabric by use of embroidery or other stitching. Needlepoint lace is made by being worked (stitched) over a paper pattern with buttonhole stitch (Preston, 1938). A pattern is first traced on to paper. The pattern is then traced around with the coarser trace thread (the cordonnet), and the cordonnet is stitched to the pattern with a sewing thread at intervals. Buttonhole stitch is then used over the cordonnet without stitching through the pattern paper. Buttonhole stitch itself is formed as a series of interconnected half hitches, sewn around the cordonnet base over the paper pattern. The lace is then separated from the paper with a knife or fine scissors, leaving the buttonhole stitches interconnected over the cordonnet. Needlepoint lace is stable and can be made into an almost infinite series of patterns. Needlepoint lace depends upon the base fabric for its resilience.

Bobbinet lace is one form of tulle fabric, made by wrapping the silk, rayon or nylon thread weft yarns around the vertical warp yarn along the diagonal from each side of the piece. It is sometimes also described as bobbin net, in that the formed net uses bobbins to interlace the threads to form the hexagonal shape of the net openings. The fabric thus formed therefore results in opposing hitches of weft around the warp threads to make a hexagonal ‘net’, which is extraordinarily stable. The formed tulle fabric is then used as the base for lace addition, being so light and having such great intrinsic strength. The fabric formed is uniform and flexible, with a durable quality that allows for its high strength:weight ratio.

Tatting is a needle or bobbin (shuttle) fabric, formed by interlocking loops, whorls and picots to form shaped pieces of fabric. Tatting is formed either with a shuttle, with a blunt needle or with a crochet hook and blunt needle (cro-tatting). Shuttle tatting is made by passing a loaded shuttle of cotton thread by hand over and around the thread as a half hitch, to form loops and rings into chains that are intertwined to form the pattern. A loop that is left through the normal double stitch (the double stitch is a ring hitch or cow hitch) is used to form a tricot structure that is later used to connect rings and loops. Needle tatting is made by casting a series of ring hitch loops over a smooth untapered needle, through the eye of which is cast either a single or double thread. When the loops have all been cast onto the needle, the needle and thread(s) are pulled through to support the formed loops. Needle tatting is looser than shuttle tatting and depends on the thickness of the needle for the final fabric. Crochet tatting (cro-tatting) uses a tatting needle with a crochet hook at the end. The stitches are cast into rings with the tatting needle and then arches, whorls and other shapes are crocheted with the hook.

URL: https://www.sciencedirect.com/science/article/pii/B9781845697570500131

Over the last decade, computer-based devices associated with the internet have significantly changed the life of human beings by carrying vast amounts of data that mostly interact with our surroundings. With tremendous development in scientific and industrial techniques, electronic devices, computing, and communications have brought technology closer to the human body. Presently electronic devices have progressed and emerged in many shapes, models, and different hardware and software configurations. Moreover, these devices collect data to expedite the relationship between devices and the environment. Devices worn near the body are as popular as smartwatches; smart bands provide ongoing connectivity, which combined with smartphones facilitates data collection and interface connectivity more efficiently. For that reason, wearable devices are likely to be built from well-designed devices that might contain sensors, batteries, microprocessors, displays, communication units, etc. In addition, wearable devices have a different appearance to traditional electronic devices, and can be formed, stretched, and patched to an item of clothing, the skin, or even implanted into the human body (Amjadi et al., 2016; Gonçalves, Ferreira da Silva, Gomes, & Simoes, 2018; Heo et al., 2017; Kutilek et al., 2017).

By considering this information, electronic textiles are ideal media for devices because they are lightweight, wearable, and flexible, but most importantly they are comfortable. Hence, e-textiles are now part of the electronic wear or body attachable category because they can attain interconnectivity and interoperability between several textile substances and electronic devices.

Thin-film transistors: Thin-film transistors (TFTs) are important components compared to traditional electronic devices. Mostly, TFTs are formulated on a planar substrate like glass or plastic substrate in a level-by-level structure. In traditional electronics, various semiconductors are employed as metal oxides, organics, and carbon nanotubes. On the other hand, for automatic flexibility and lower-temperature processability the research community has focused on organic semiconductors and is now turning its attention to the presentation and strength of TFTs.

Memory devices: In any kind of material, memory devices are a curiosity in role of data-storage devices crucial to understanding complicated electronic structures on textiles. Various authors have presented different solutions for memory devices. Some are nonvolatile memory devices with dip-n-dry-processed graphene or have a nylon thread memory function comparable to write-once-read-many memory mechanisms. Most of the memory mechanisms or devices have been successively formulated on fibers, which endorses the understanding of new theoretical wearable electronics. Researchers have focused on high-range data storage, novel integration schemes, and operational functionalities with other electronics.

Displays: As we know, textile-based devices have a considerable relevance to wearable electronics. Traditional light-emitting diodes are large in size, a thickness that is counter to the exclusive properties of textiles. With the progression of organic light-emitting diodes (OLEDs), fiber-type OLED devices became possible. But various issues have been raised about their performance and stability in textile-based displays. A proper, modern, and intelligent structure should be needed for oxygen and water molecules which usually guide to a momentous descent of device presentation, steadiness. So, there is a need for an accurate encapsulation structure and rough substrate surface, which along with high voltage should be mitigated or adopted in textile-based OLEDs.

Solar cells: In textile-based electronics, energy harvesting devices are significant for self-powered progression. Of all the energy harvest devices, solar cells can be implanted in textiles because of their straightforward device configuration. Stretchable dye-sensitized solar cells (DSSCs), flexible, elastic fiber-formed polymer solar cells (PSCs), organic–inorganic methylammonium lead trihalide perovskite as a radiance absorption layer, fiber-type double-twisted perovskite solar cells using carbon nanotube fibers, and double-twisted architecture solar cells that can be attained by twisting a perfect carbon fiber are some well-organized solar energy-harvesting solutions. However, the presentation of solar cells has been enhanced over the past few years and problems such as atmosphere steadiness, interconnectivity, washability, and inefficient units need to be resolved (Amjadi et al., 2016; Heo et al., 2017).

Nanaogenerators: Basically, in text-based electrical sensors, usage of ordinary batteries might be difficult because of their heavy weight, structural design, and safety issues; moreover, timely charging is a crucial concern. Hence, batteries as power sources and the integration of self-power generating devices can be useful. Polyvinylidene fluoride and polytetrafluoroethylene are some of the ways to gain energy, which are used as piezoelectric components.

Energy storage devices: While designing textile sensors it is also important to look at the energy storage unit. Different researchers have proposed various materials and services for energy storage. Most of these are based on the improvement of supercapacitors. However, there is the issue of supercapacitor performance; and safety is also a matter of concern. Material components like liquids, gels, and solid state materials can be toxic to the human body. For this reason, usage of nontoxic and nonflammable materials like sodium and lithium sulfate are ideal for alleviating safety concerns (Amjadi et al., 2016; Heo et al., 2017).

URL: https://www.sciencedirect.com/science/article/pii/B9780128196649000090

Viktor V. Babenko, ... Inwon Lee, in Boundary Layer Flow over Elastic Surfaces, 2012

The presence of low concentrations (10−3–10−1 kg/m3) of some polymers (for example, guar, polyethylenoxid WSR-301, collagen etc.) essentially reduces shear stresses [114, 193, 221, 227, 238, 275, 284, 332, 341, 351, 352, 383, 394, 404, 405, 425, 426, 449, 450, 486, 499, 509][114][193][221][227][238][275][284][332][341][351][352][383][394][404][405][425][426][449][450][486][499][509] in shear flows (known as the Thoms effect).

The effect of drag reduction does not depend on the absorption properties of a surface and, as a result, on the amount of the polymer additive molecules settled on the wall, but rather is determined by properties of the molecules in the shear flow [449].

Only those polymers with molecules that have the ability to unfold and stretch along the direction of streamlines have the property to reduce drag [404, 405, 425, 426, 449, 450][404][405][425][426][449][450]. The same effect can be achieved in the presence of suspensions of solid oblong shaped particles, such as asbestos and paper filaments,

Seks Bestiality Tube New

Latin Theme

Nurse Stripes

Crystal Rush New Porn 2021

Long Hair Sex Tamil

Nylon Thread - an overview | ScienceDirect Topics

Nylon Thread - Item - World of Warcraft

What Is Nylon Thread? (with pictures) - Info Bloom

Nylon Thread Guide - The Thread Exchange

Bonded Nylon Thread | Nylon Thread | 69 Nylon Thread ...

Nylon - Wikipedia

Coats Nylbond | Bonded Nylon | Thread Manufacture | Coats ...

Nylon Thread