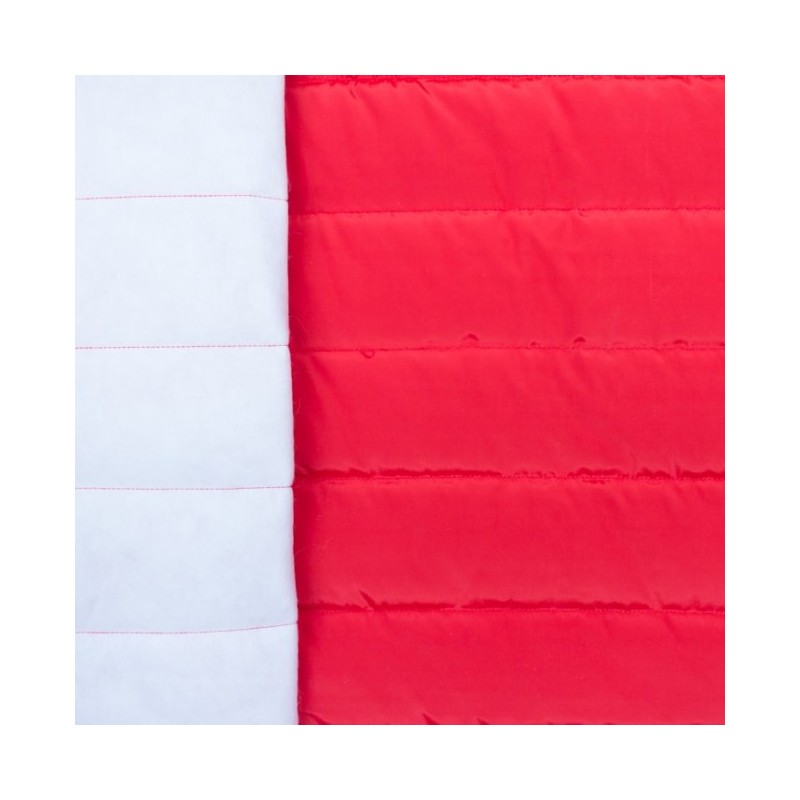

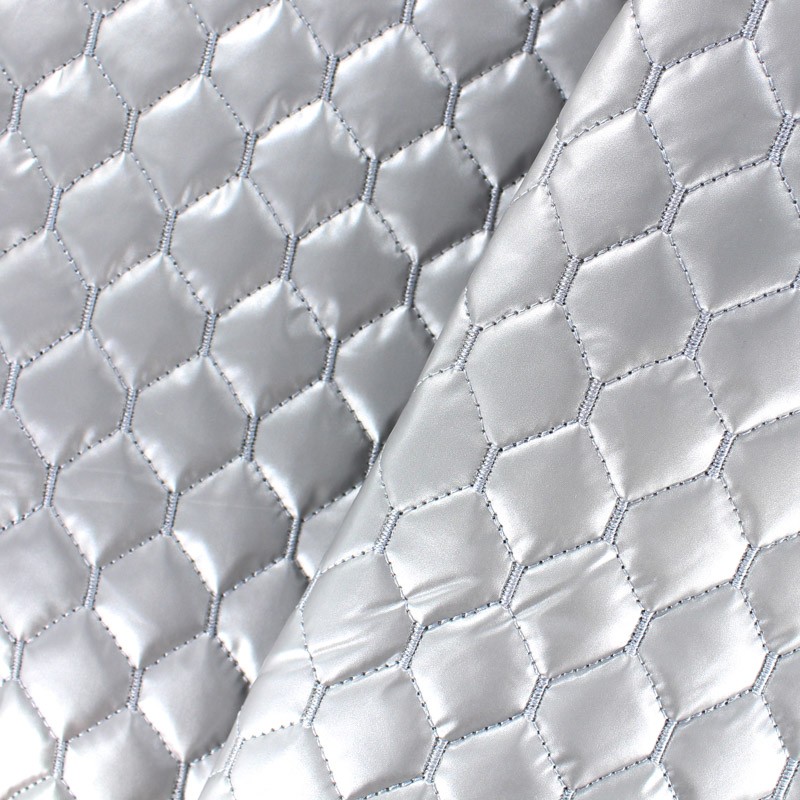

Nylon Lining

👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

https://ukfabricsonline.com/nylon-lining

Перевести · A thin, lightweight Nylon lining fabric. This is a smooth feeling, very lightweight nylon that serves as a standard cheap lining or even dust …

https://www.etsy.com/market/nylon_lining

Перевести · Check out our nylon lining selection for the very best in unique or custom, handmade pieces from our …

https://en.m.wikipedia.org/wiki/Nylon

Ориентировочное время чтения: 8 мин

Опубликовано: 27.07.2001

Above their melting temperatures, Tm, thermoplastics like nylon are amorphous solids or viscous fluids in which the chains approximate random coils. Below Tm, amorphous regions alternate with regions which are lamellar crystals. The amorphous regions contribute elasticity and the crystalline regions contribute strength and rigidity. The planar amide (-CO-NH-) groups are very polar, so nylo…

Above their melting temperatures, Tm, thermoplastics like nylon are amorphous solids or viscous fluids in which the chains approximate random coils. Below Tm, amorphous regions alternate with regions which are lamellar crystals. The amorphous regions contribute elasticity and the crystalline regions contribute strength and rigidity. The planar amide (-CO-NH-) groups are very polar, so nylon forms multiple hydrogen bonds among adjacent strands. Because the nylon backbone is so regular and symmetrical, especially if all the amide bonds are in the trans configuration, nylons often have high crystallinity and make excellent fibers. The amount of crystallinity depends on the details of formation, as well as on the kind of nylon.

Nylon 66 can have multiple parallel strands aligned with their neighboring peptide bonds at coordinated separations of exactly 6 and 4 carbons for considerable lengths, so the carbonyl oxygens and amide hydrogens can line up to form interchain hydrogen bonds repeatedly, without interruption (see the figure opposite). Nylon 510 can have coordinated runs of 5 and 8 carbons. Thus parallel (but not antiparallel) strands can participate in extended, unbroken, multi-chain β-pleated sheets, a strong and tough supermolecular structure similar to that found in natural silk fibroin and the β-keratins in feathers. (Proteins have only an amino acid α-carbon separating sequential -CO-NH- groups.) Nylon 6 will form uninterrupted H-bonded sheets with mixed directionalities, but the β-sheet wrinkling is somewhat different. The three-dimensional disposition of each alkane hydrocarbon chain depends on rotations about the 109.47° tetrahedral bonds of singly bonded carbon atoms.

When extruded into fibers through pores in an industry spinneret, the individual polymer chains tend to align because of viscous flow. If subjected to cold drawing afterwards, the fibers align further, increasing their crystallinity, and the material acquires additional tensile strength. In practice, nylon fibers are most often drawn using heated rolls at high speeds.

Block nylon tends to be less crystalline, except near the surfaces due to shearing stresses during formation. Nylon is clear and colorless, or milky, but is easily dyed. Multistranded nylon cord and rope is slippery and tends to unravel. The ends can be melted and fused with a heat source such as a flame or electrode to prevent this.

Nylons are hygroscopic, and will absorb or desorb moisture as a function of the ambient humidity. Variations in moisture content have several effects on the polymer. Firstly, the dimensions will change, but more importantly moisture acts as a plasticizer, lowering the glass transition temperature (Tg), and consequently the elastic modulus at temperatures below the Tg

When dry, polyamide is a good electrical insulator. However, polyamide is hygroscopic. The absorption of water will change some of the material's properties such as its electrical resistance. Nylon is less absorbent than wool or cotton.

Characteristics

The characteristic features of nylon 6,6 include:

• Pleats and creases can be heat-set at higher temperatures

• More compact molecular structure

• Better weathering properties; better sunlight resistance

• Softer "Hand"

• High melting point (256 °C, 492.8 °F)

• Superior colorfastness

• Excellent abrasion resistance

On the other hand, nylon 6 is easy to dye, more readily fades; it has a higher impact resistance, a more rapid moisture absorption, greater elasticity and elastic recovery.

• Variation of luster: nylon has the ability to be very lustrous, semi-lustrous or dull.

• Durability: its high tenacity fibers are used for seatbelts, tire cords, ballistic cloth and other uses.

• High elongation

• Excellent abrasion resistance

• Highly resilient (nylon fabrics are heat-set)

• Paved the way for easy-care garments

• High resistance to insects, fungi, animals, as well as molds, mildew, rot and many chemicals

• Used in carpets and nylon stockings

• Melts instead of burning

• Used in many military applications

• Good specific strength

• Transparent to infrared light (−12 dB)

Flammability

Nylon clothing tends to be less flammable than cotton and rayon, but nylon fibers may melt and stick to skin.

Environmental impact, incineration and recycling

https://www.ebay.co.uk/b/Nylon-Lining-Fabric/28162/bn_7023619912

Перевести · Taupe Remnant of Nylon Lining = 32 ¼” wide x 48 ½” long. £2.99. 0 bids. Free postage. Ending Today at 11:25PM GMT. 1h 10m.

Oberon Design Ballistic Nylon Lining for Handbags and Messenger Bags

Seamstick Basting Tape for Dacron, Nylon, Vinyl & Home Sewing

Lining nylon attack shuttle slow 75 unboxing

Prom Gown Sew Along 2017: Use Nylon Boning to Shape Bodice

China Workout Clothes Manufacturer Wholesale Nylon Lining Dry Fit Women Sport Running Gym Shorts

https://www.amazon.com/braided-nylon-line/s?k=braided+nylon+line

Перевести · INNOCEDEAR Double-Braided Nylon Dock Line (Navy Blue,Professional Boat Rope,L: 15 ft. D: 1/2 inch Eyelet: 12 inch, 4 Pack).Hi-Performance Marine Boats Mooring Rope Dock Line …

https://www.martrim.co.uk/car-trimming-supplies/brush-nylon-headlining.php

Перевести · Nylon headlining can give your vehicle interior a functional, yet sleek and stylish finish. At the same time, it's a highly economical product and we are confident that our …

https://m.youtube.com/watch?v=gdfNFWMVVEI

Перевести · 25.03.2018 · Albright knot join braided line to nylon line - YouTube. Albright knot join braided line to nylon line…

https://m.indiamart.com/impcat/nylon-monofilament-line.html

Перевести · Nylon Wire Monofilament. ₹ 190/ Dozen Get Latest Price. Usage: Nylon wire (monofilament) used in many industries and fising line. Usage/Application: For fishing line, monofilament wire. Color: White. Size/Length: Available in 40, 45, 50, 60, 70, 80, 90, 100, & 200. Nylon wire fishing line…

https://www.kurpirkt.lv/rus/result.php?q=nylon+line

Nylon line cena interneta veikalos ir no 5€ līdz 22 €, kopā ir 11 preces divos veikalos ar nosaukumu 'nylon line'. Meklē 12,2 milj. …

Не удается получить доступ к вашему текущему расположению. Для получения лучших результатов предоставьте Bing доступ к данным о расположении или введите расположение.

Не удается получить доступ к расположению вашего устройства. Для получения лучших результатов введите расположение.

Nylon is a generic designation for a family of synthetic polymers composed of polyamides (repeating units linked by amide links).[a][1][2] Nylon is a thermoplastic silky material,[3] generally made from petroleum,[4] that can be melt-processed into fibers, films, or shapes.[5]:2 Nylon polymers can be mixed with a wide variety of additives to achieve many different property variations. Nylon polymers have found significant commercial applications in fabric and fibers (apparel, flooring and rubber reinforcement), in shapes (molded parts for cars, electrical equipment, etc.), and in films (mostly for food packaging).[6]

Nylon was the first commercially successful synthetic thermoplastic polymer.[7] DuPont began its research project in 1927.[8] The first example of nylon, (nylon 66), was synthesized using diamines on February 28, 1935 by Wallace Hume Carothers at DuPont's research facility at the DuPont Experimental Station.[9][10] In response to Carothers' work, Paul Schlack at IG Farben developed nylon 6, a different molecule based on caprolactam, on January 29, 1938.[11]:10[12]

Nylon was first used commercially in a nylon-bristled toothbrush in 1938,[4][13] followed more famously in women's stockings or "nylons" which were shown at the 1939 New York World's Fair and first sold commercially in 1940,[14] whereupon they became an instant commercial success with 64 million pairs sold during their first year on the market. During World War II, almost all nylon production was diverted to the military for use in parachutes and parachute cord. Wartime uses of nylon and other plastics greatly increased the market for the new materials.[15]

DuPont, founded by Éleuthère Irénée du Pont, first produced gunpowder and later cellulose-based paints. Following WWI, DuPont produced synthetic ammonia and other chemicals. DuPont began experimenting with the development of cellulose based fibers, eventually producing the synthetic fiber rayon. DuPont's experience with rayon was an important precursor to its development and marketing of nylon.[16]:8,64,236

DuPont's invention of nylon spanned an eleven-year period, ranging from the initial research program in polymers in 1927 to its announcement in 1938, shortly before the opening of the 1939 New York World's Fair.[8] The project grew from a new organizational structure at DuPont, suggested by Charles Stine in 1927, in which the chemical department would be composed of several small research teams that would focus on "pioneering research" in chemistry and would "lead to practical applications".[16]:92 Harvard instructor Wallace Hume Carothers was hired to direct the polymer research group. Initially he was allowed to focus on pure research, building on and testing the theories of German chemist Hermann Staudinger.[17] He was very successful, as research he undertook greatly improved the knowledge of polymers and contributed to science.[18]

In the spring of 1930, Carothers and his team had already synthesized two new polymers. One was neoprene, a synthetic rubber greatly used during World War II.[19] The other was a white elastic but strong paste that would later become nylon. After these discoveries, Carothers' team was made to shift its research from a more pure research approach investigating general polymerization to a more practically-focused goal of finding "one chemical combination that would lend itself to industrial applications".[16]:94

It wasn't until the beginning of 1935 that a polymer called "polymer 6-6" was finally produced. Carothers' coworker, Washington University alumnus Julian W. Hill had used a cold drawing method to produce a polyester in 1930.[20] This cold drawing method was later used by Carothers in 1935 to fully develop nylon.[21] The first example of nylon (nylon 6,6) was produced on February 28, 1935, at DuPont's research facility at the DuPont Experimental Station.[9] It had all the desired properties of elasticity and strength. However, it also required a complex manufacturing process that would become the basis of industrial production in the future. DuPont obtained a patent for the polymer in September 1938,[22] and quickly achieved a monopoly of the fiber.[18] Carothers died 16 months before the announcement of nylon, therefore he was never able to see his success.[8]

The production of nylon required interdepartmental collaboration between three departments at DuPont: the Department of Chemical Research, the Ammonia Department, and the Department of Rayon. Some of the key ingredients of nylon had to be produced using high pressure chemistry, the main area of expertise of the Ammonia Department. Nylon was considered a “godsend to the Ammonia Department”,[16] which had been in financial difficulties. The reactants of nylon soon constituted half of the Ammonia department's sales and helped them come out of the period of the Great Depression by creating jobs and revenue at DuPont.[16]

DuPont's nylon project demonstrated the importance of chemical engineering in industry, helped create jobs, and furthered the advancement of chemical engineering techniques. In fact, it developed a chemical plant that provided 1800 jobs and used the latest technologies of the time, which are still used as a model for chemical plants today.[16] The ability to acquire a large number of chemists and engineers quickly was a huge contribution to the success of DuPont's nylon project.[16]:100–101 The first nylon plant was located at Seaford, Delaware, beginning commercial production on December 15, 1939. On October 26, 1995, the Seaford plant was designated a National Historic Chemical Landmark by the American Chemical Society.[23]

An important part of nylon's popularity stems from DuPont's marketing strategy. DuPont promoted the fiber to increase demand before the product was available to the general market. Nylon's commercial announcement occurred on October 27, 1938, at the final session of the Herald Tribune's yearly "Forum on Current Problems", on the site of the approaching New York City world's fair.[17][18]:141 The "first man-made organic textile fiber" which was derived from "coal, water and air" and promised to be "as strong as steel, as fine as the spider's web" was received enthusiastically by the audience, many of them middle-class women, and made the headlines of most newspapers.[18]:141 Nylon was introduced as part of "The world of tomorrow" at the 1939 New York World's Fair[24] and was featured at DuPont's "Wonder World of Chemistry" at the Golden Gate International Exposition in San Francisco in 1939.[17][25] Actual nylon stockings were not shipped to selected stores in the national market until May 15, 1940. However, a limited number were released for sale in Delaware before that.[18]:145–146 The first public sale of nylon stockings occurred on October 24, 1939, in Wilmington, Delaware. 4,000 pairs of stockings were available, all of which were sold within three hours.[17]

Another added bonus to the campaign was that it meant reducing silk imports from Japan, an argument that won over many wary customers. Nylon was even mentioned by President Roosevelt's cabinet, which addressed its "vast and interesting economic possibilities" five days after the material was formally announced.[18]

However, the early excitement over nylon also caused problems. It fueled unreasonable expectations that nylon would be better than silk, a miracle fabric as strong as steel that would last forever and never run.[18]:145–147[14] Realizing the danger of claims such as "New Hosiery Held Strong as Steel" and "No More Runs", DuPont scaled back the terms of the original announcement, especially those stating that nylon would possess the strength of steel.[18]

Also, DuPont executives marketing nylon as a revolutionary man-made material did not at first realize that some consumers experienced a sense of unease and distrust, even fear, towards synthetic fabrics.[18]:126–128 A particularly damaging news story, drawing on DuPont's 1938 patent for the new polymer, suggested that one method of producing nylon might be to use cadaverine (pentamethylenediamine),[b] a chemical extracted from corpses. Although scientists asserted that cadaverine was also extracted by heating coal, the public often refused to listen. A woman confronted one of the lead scientists at DuPont and refused to accept that the rumour was not true.[18]:146–147

DuPont changed its campaign strategy, emphasizing that nylon was made from "coal, air and water", and started focusing on the personal and aesthetic aspects of nylon, rather than its intrinsic qualities.[18]:146–147 Nylon was thus domesticated,[18]:151–152 and attention shifted to the material and consumer aspect of the fiber with slogans like "If it's nylon, it's prettier, and oh! How fast it dries!".[16]:2

After nylon's nationwide release in 1940, production was increased. 1300 tons of the fabric were produced during 1940.[16]:100 During their first year on the market, 64 million pairs of nylon stockings were sold.[16]:101 In 1941, a second plant was opened in Martinsville, Virginia due to the success of the fabric.[26]

While nylon was marketed as the durable and indestructible material of the people, it was sold at almost twice the price of silk stockings ($4.27 per pound of nylon versus $2.79 per pound of silk).[16]:101 Sales of nylon stockings were strong in part due to changes in women's fashion. As Lauren Olds explains: "by 1939 [hemlines] had inched back up to the knee, closing the decade just as it started off". The shorter skirts were accompanied by a demand for stockings that offered fuller coverage without the use of garters to hold them up.[27]

However, as of February 11, 1942, nylon production was redirected from being a consumer material to one used by the military.[17] DuPont's production of nylon stockings and other lingerie stopped, and most manufactured nylon was used to make parachutes and tents for World War II.[28] Although nylon stockings already made before the war could be purchased, they were generally sold on the black market for as high as $20.[26]

Once the war ended, the return of nylon was awaited with great anticipation. Although DuPont projected yearly production of 360 million pairs of stockings, there were delays in converting back to consumer rather than wartime production.[17] In 1946, the demand for nylon stockings could not be satisfied, which led to the Nylon riots. In one instance, an estimated 40,000 people lined up in Pittsburgh to buy 13,000 pairs of nylons.[14] In the meantime, women cut up nylon tents and parachutes left from the war in order to make blouses and wedding dresses.[29][30] Between the end of the war and 1952, production of stockings and lingerie used 80% of the world's nylon. DuPont put a lot of focus on catering to the civilian demand, and continually expanded its production.

As pure nylon hosiery was sold in a wider market, problems became apparent. Nylon stockings were found to be fragile, in the sense that the thread often tended to unravel lengthwise, creating 'runs'.[16]:101 People also reported that pure nylon textiles could be uncomfortable due to nylon's lack of absorbency.[31] Moisture stayed inside the fabric near the skin under hot or moist conditions instead of being "wicked" away.[32] Nylon fabric could also be itchy, and tended to cling and sometimes spark as a result of static electrical charge built up by friction.[33][34] Also, under some conditions stockings could decompose[18] turning back into nylon's original components of air, coal, and water. Scientists explained this as a result of air pollution, attributing it to London smog in 1952, as well as poor air quality in New York and Los Angeles.[35][36][37]

T

Mistress Di

Brooke Little Porn

Klixen Porn New

Kinky Party 18

Amateur Pussy Lick Orgasm

Nylon Lining - UK Fabrics Online

Nylon lining | Etsy

Nylon - Wikipedia

Nylon Lining Fabric - eBay

Amazon.com: braided nylon line

Brush Nylon Headlining - Martrim Car Trimming Supplies

Nylon Monofilament Line - Nylon Monofilament Yarn Latest ...

Nylon line cena no 5€ līdz 22€ - KurPirkt.lv

Nylon Lining