Not known Facts About Effective Prototyping De-Risks Product Innovation

Not known Factual Statements About Creative Prototyping for Medical Device Product Development

Extreme Expenses Are Not For intricate products, there's simply no way around the iterative nature of the prototyping procedure. There is, nevertheless, a method to make an end-run around the excessive costs and extended time horizons that frequently accompany it. Achieving this needs high levels of integration. To put Source , the prototyping process must not be misinterpreted as a job for which only the design team is mainly responsible.

To do this needs 2 things. First, a one-source company design that integrates design, engineering, and manufacturing. Second, a desired sub-specialty, called Style For Manufacture (DFM). The combination of both ensures that these phases are incorporated and that each is undertaken with scalable production in mind. At Pivot International, our one-source service model and industry-leading DFM knowledge makes us a proven and preferred partner to business worldwide.

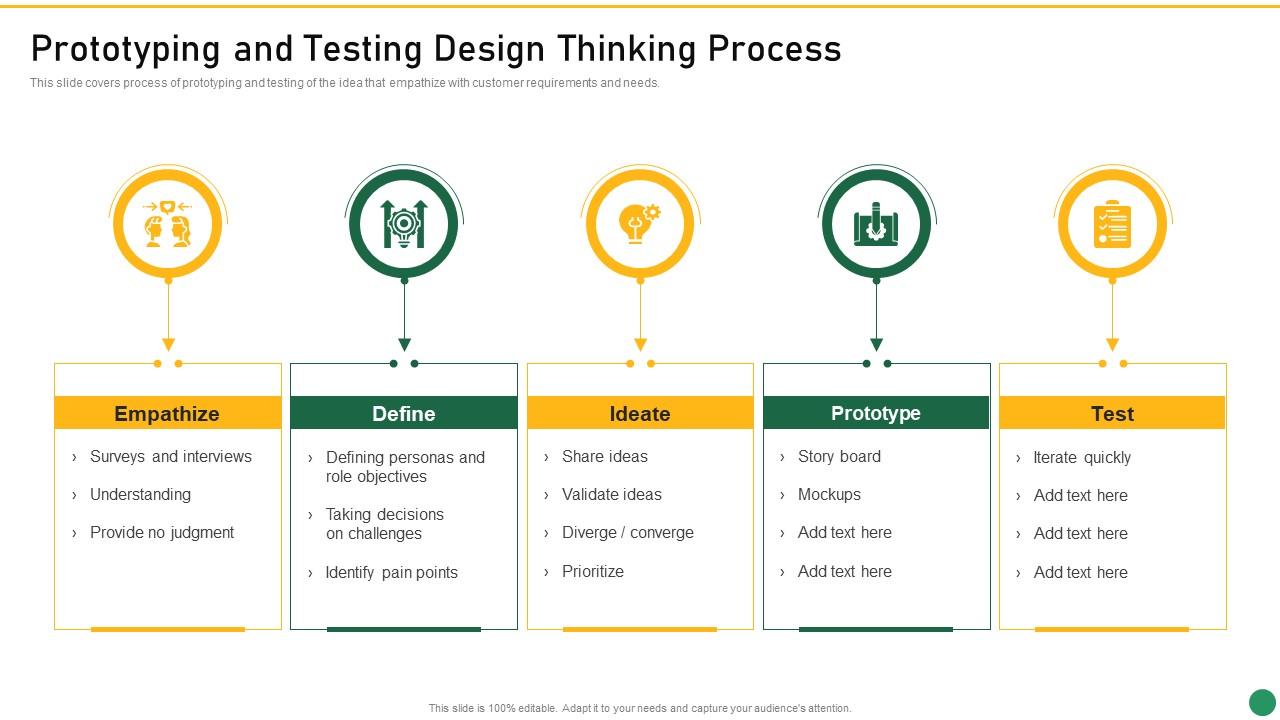

Ideating Empathizing Prototyping Design Thinking Loop Set 1 Innovation Product Development - Presentation Graphics - Presentation PowerPoint Example - Slide Templates

Ideating Empathizing Prototyping Design Thinking Loop Set 1 Innovation Product Development - Presentation Graphics - Presentation PowerPoint Example - Slide Templates Moving Your Product From Prototype to Production

Moving Your Product From Prototype to ProductionWith 320,000 square feet of tri-continental manufacturing might, we provide versatile production runs and the ability to easily move production in between places to support your distribution needs. Let's explore the prototyping procedure to much better understand what it requires. Understanding the Prototyping Process Although the wider prototyping process can involve more than ten versions, models normally fall into three classifications: 1.

These "dummy" prototypes are most frequently developed for usage in crowdsourcing campaigns or promotion stunts developed to develop high levels of anticipation for an item that is not yet readily available. Look models are generally created using CAD illustrations and 3D printing (additive production) technology. 2."Works-Like" Models Works-like prototypes are early Proof of Idea (POC) models.

INNOVATIVE PRODUCTS - Astarte Strategies

INNOVATIVE PRODUCTS - Astarte StrategiesUnknown Facts About The Ultimate Guide To Rapid Prototyping For Successful

Unlike looks-like prototypes, works-like models seldom look anything like the finished product. Rather, their aim is to figure out if the item will satisfy minimum viability requirements. POC's play a special function in verifying high-risk aspects of style. For this reason, they are an essential piece of gaining or keeping investor buy-in to guarantee an item is adequately capitalized for further development.

Functional Prototypes Fully-fledged practical prototypes represent varying combinations of looks-like and works-like prototypes and normally fall into three classifications: Engineering Prototypes are needed for evaluating an item's efficiency. While earlier prototyping efforts might have tested specific parts or components, engineering models make sure the item operates well as a whole. In spite of its name, engineering models need to always go hand in hand with style.