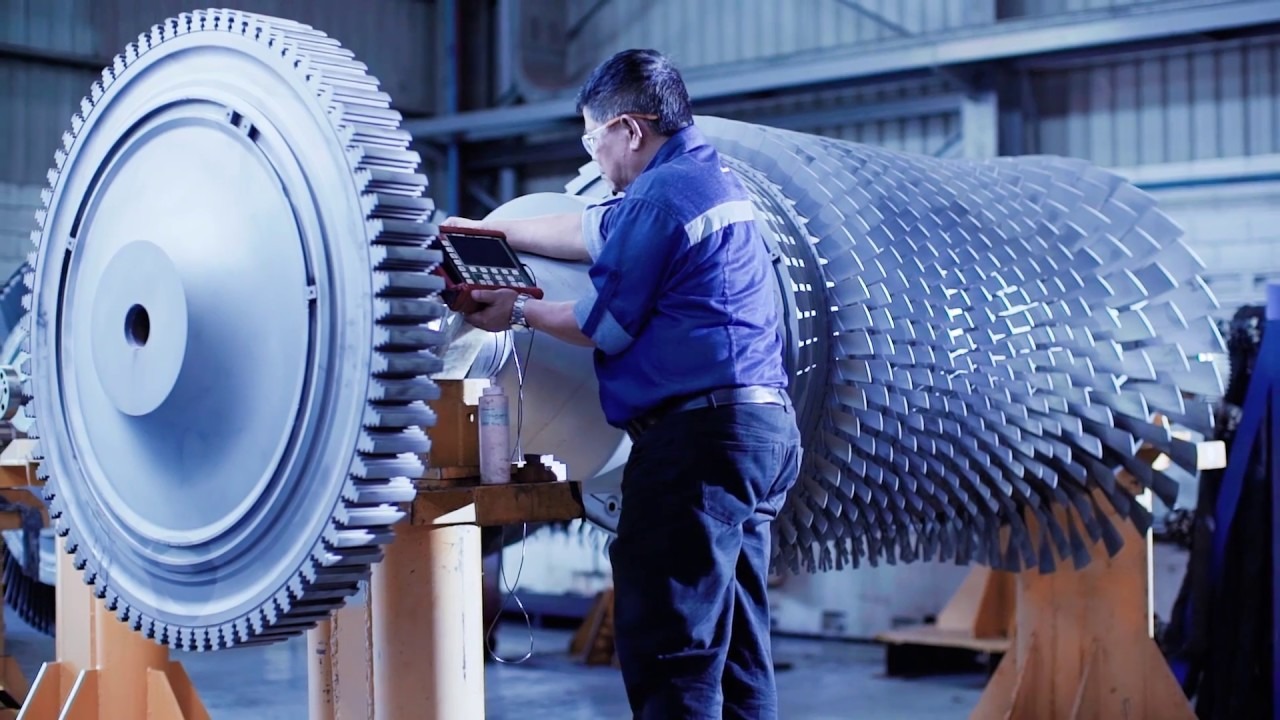

More Essential Tips for Maintaining Your Rotating Equipment!

Standard cleansing of rotating devices is crucial to the appropriate general performance of preventive maintenance. Cleansing your rotating devices can don't just help minimize vibration ranges and enhance Total functionality, but It is additionally necessary for complete and accurate inspections. Simply put, cleaning equipment allows you to see any faults or issues that must be corrected.

Ensure Right Alignment

Among the list of significant facets of the continual Procedure of rotating gear is proper alignment. Effectively modified rotating equipment decreases vibration levels, lowers don, reduces the chance of shaft exhaustion and sudden failure, extends element existence, and decreases Electrical power usage. Appropriate applications and drills are essential for appropriately leveling rotating products, so don't skimp on this component.

Listen to Uncommon Sounds

When inspecting rotating equipment for instance a pump, your ears are a terrific tool for identifying likely complications. Listen while the tools are working and watch out for uncommon sounds. Bizarre noises are sometimes a warning indicator the tools are not Functioning thoroughly, and it is important to test to acquire the basis of the issue.

Feel The Weird Vibrations

High vibration levels inside your rotating equipment can shorten the lifetime of couplings, seals, bearings, and various crucial factors. As outlined by some calculations, minimizing the vibration stage of the apparatus by just 10% can maximize bearing lifestyle by all over 40%! One way to decrease vibration is to use a guide balancing method that needs balancing rotating machines or shutting down the equipment, or working with Lively balancing engineering that can be corrected through the equipment operates.

Hold All Rotating Gear Lubricated

it really works, so it must be lubricated. Lubricating oil is very important for the wellbeing of your rotating products. The situation in the lubricating oil/grease ought to be checked consistently and regreased if required. Proper bearing upkeep will go a good distance in averting bearing repairs.

Examine All Bolts

As rotating tools functions as time passes, the bolts can loosen, producing too much vibration as well as other difficulties. Usually, be certain the bolts are properly tightened when inspecting your rotating devices.

By Placing these procedures in place, it is possible to extend the daily life of your tools, improve overall effectiveness, and lessen high-priced repairs and downtime. Keep in mind that preventative do the job requires consistent commitment to generally be actually productive. If you need to employ the Rotating Equipment Services, check the connected source, and get help from experts!