Mold Your Success: Unlocking the Potential with Injection Molder Services

In the ever-evolving landscape of manufacturing and production, businesses are constantly seeking innovative solutions to enhance efficiency and quality. This quest for excellence has led many companies to embrace the benefits of injection molder services. These specialized services offer a crucial avenue for businesses to transform their production processes and unlock their full potential.

By leveraging the expertise and capabilities of injection molders, businesses can optimize their manufacturing operations, reduce costs, and enhance product quality. Whether you are a small business looking to scale up production or a large corporation aiming to streamline processes, injection molder services can play a pivotal role in driving your success. Partnering with experienced professionals in this field can open up a world of possibilities, allowing you to stay ahead of the competition and meet the demands of a dynamic market.

Types of Injection Molding Processes

Injection molding is a versatile manufacturing process that can be tailored to suit different production needs. One type of injection molding process is known as thermoplastic injection molding. This method involves melting plastic material to a liquid state, injecting it into a mold, and then allowing it to cool and solidify. Another type is thermoset injection molding, which involves curing the plastic material using heat or chemical reactions after it has been injected into the mold. By understanding the differences between these processes, businesses can choose the most suitable method for their product requirements.

Additionally, there is a process called liquid silicone rubber (LSR) injection molding, which is ideal for producing parts that require flexibility, durability, and high precision. LSR injection molding involves injecting liquid silicone rubber into a mold cavity, where it undergoes a quick curing process to form the desired product. This method is commonly used in industries such as automotive, medical, and electronics to create components with excellent temperature resistance and biocompatibility.

Furthermore, overmolding is a specialized injection molding process that involves combining multiple materials to create a single finished product. This process is commonly used to add features like grips, soft-touch surfaces, or multiple colors to a product. By understanding the various types of injection molding processes available, businesses can unlock new possibilities for product design and functionality.

Benefits of Using Injection Molder Services

Experience Increased Efficiency:

Utilizing injection molder services enables businesses to streamline their production processes, leading to enhanced efficiency and quicker turnaround times. By leveraging the expertise of experienced professionals in injection molding, companies can optimize their manufacturing operations and meet tight deadlines with ease.

Achieve Cost Savings:

One of the key advantages of using injection molder services is the potential for cost savings. Through economies of scale and specialized equipment, businesses can produce high-quality plastic components at a lower cost per unit. This can result in significant savings compared to in-house production or other manufacturing methods.

Access to Advanced Technology:

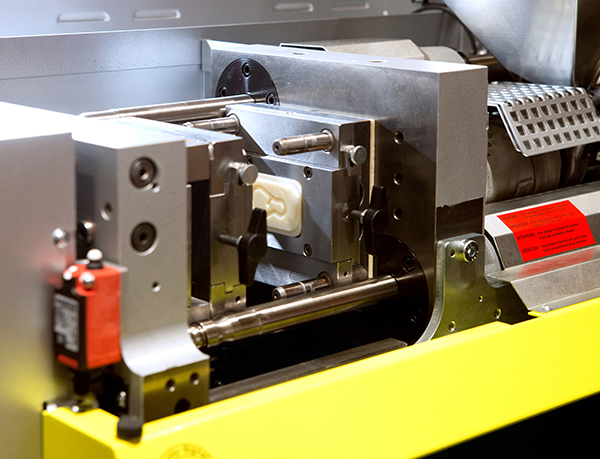

Injection molder services often come equipped with state-of-the-art technology and machinery that may be financially prohibitive for some businesses to acquire independently. By partnering with a reputable service provider, companies can leverage cutting-edge equipment and processes to produce precise and complex plastic parts efficiently.

Key Considerations when Choosing an Injection Molding Service Provider

Firstly, it is important to assess the reputation and experience of the injection molder service provider. Look for companies that have a proven track record in delivering high-quality products and have satisfied clientele. A provider with extensive experience is more likely to understand the intricacies of injection molding and offer solutions tailored to your specific needs.

Secondly, consider the range of services offered by the injection molder service provider. injection molds may specialize in certain types of materials or production volumes, so it's essential to ensure that the service provider can meet your requirements. Look for flexibility and the ability to handle custom projects or unique specifications that your business may have.

Lastly, pricing and cost efficiency are crucial factors when selecting an injection molder service provider. While it may be tempting to opt for the cheapest option, it is essential to strike a balance between cost and quality. Request quotes from multiple providers and compare not only the pricing but also the value-added services, such as design assistance and prototyping, that they offer to help you make an informed decision.