Maximize Your Excavator Excavator's Performance: Critical Parts to Evaluate

When it comes to using a Cat excavator, enhancing performance is crucial for getting the job done quickly and effectively. These powerful machines are engineered to tackle a variety of tasks, such as building and earth moving to material handling and landscaping. However, the performance of your Caterpillar excavator significantly depends on the state and performance of its essential components. Knowing which parts play a key role can make all the change in making sure your equipment runs smoothly and lasts more years.

In this piece, we will delve into the essential parts of Cat excavators that you should consider to improve their performance. Whether a veteran operator or a novice to the realm of heavy machinery, recognizing the importance of Cat parts will enable you make smart decisions about upkeep and upgrades. By prioritizing these crucial components, you can improve productivity, reduce downtime, and ensure your excavator stays in optimal working shape for all your projects.

Essential Elements of Caterpillar Excavation Equipment

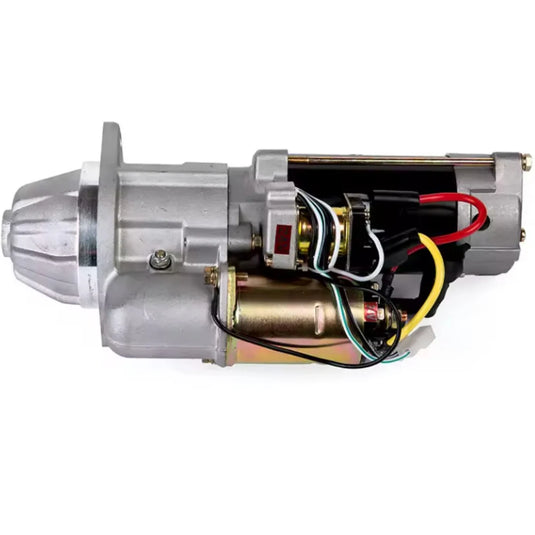

Caterpillar excavators are famous for their sturdy design and outstanding performance, mainly resulting from their essential components. The engine is one of the most critical parts, as it operates the entire unit. Caterpillar engines are engineered for superior fuel efficiency and can deliver high torque at low speeds, enabling effective digging and lifting capabilities. Consistent upkeep of the engine, such as oil changes and filter replacements, is vital for maximizing performance and longevity.

Another significant component is the hydraulic system, which is in charge of powering the boom, arm, and bucket. fuel injector replacement cost consists of hydraulic pumps, cylinders, and hoses that work together to generate the force needed for various excavation tasks. Components like hydraulic filters and fluid should be monitored and renewed regularly to ensure effective operation and prevent expensive breakdowns. A carefully tended hydraulic system leads to enhanced responsiveness and accuracy in the machine's movements.

The undercarriage is also vital to the overall performance of Caterpillar excavators. It consists of the tracks, roller frames, and idlers, all important for stability and agility on various terrains. Frequent evaluation of the undercarriage parts can prevent problems such as uneven wear and track misalignment, which can substantially affect the machine's mobility. Purchasing high-quality Cat parts for the undercarriage can enhance durability and reduce downtime, leading to increased productivity on the job site.

Preservation Advice for Optimal Performance

Regular maintenance is essential for maximizing the functionality of your Caterpillar excavator. Commence by creating a scheduled review plan. Inspect fluid levels, which includes hydraulic oil, engine oil, and coolant, to ensure they are at the specified quantities. Look for any evidence of leaks or odd noises that could signal underlying issues. Identifying problems early can help prevent costly repairs and downtime.

Keep the filters in your excavator clear and replaced as needed. This includes fuel filters, oil filters, and hydraulic filters. Clogged filters can cause reduced efficiency and elevated strain on the engine and hydraulic system. Following the manufacturer’s recommendations for filter changes is essential to maintaining optimal operation and extending the life of your machine.

Additionally, pay close attention to the tracks and undercarriage components. Consistently inspect for wear and tear, and ensure that the track tension is adequately adjusted. Unequal tension can lead to uneven wear and influence the overall performance of the excavator. Properly maintaining the tracks will enhance stability and lengthen the life of your CAT excavator, ensuring it runs at optimal efficiency.

Enhancing Parts for Better Performance

Enhancing the components of your Cat excavator can significantly improve its effectiveness. One of the initial areas to address is the hydraulic system. Swapping out antique hydraulic parts with newer, efficient models can lower fuel usage while improving hoisting and digging power. Better hydraulics also translate to quicker cycle times, which can lead to increased efficiency on the work site.

Another important change is the undercarriage components. High-quality tracks, rollers, and idlers can provide improved support and grip, especially in difficult terrains. Purchasing high-quality and reliable undercarriage components not only extends the lifespan of your excavator but also provides better operation and superior fuel economy. With improved ground contact and hold, your machine can perform tasks more effectively and with less strain.

Finally, think about enhancing the powertrain parts. Employing Cat components designed for maximum performance can lead to significant improvements in gas mileage and performance. Improving filters, injectors, and exhaust systems can lower emissions while enhancing throttle performance. By concentrating on these key parts, you can guarantee that your Caterpillar excavator functions at its best, ultimately leading to improved construction site effectiveness and decreased overhead.