Main challenges of metal 3D printing technology

Zeal 3D PrintingOf the many 3D printing services in Australia, metal 3D printing services have become uniquely sought after. There are advantages to this form of online 3D printing.

Why all the hype around metal 3D printing?

In an age of custom 3D printed parts and rapid prototyping services, the advent of metal 3D printing has been another unique phenomenon. Apart from its ability to facilitate a reduction in overall costs and time of production, the technology is capable of directly printing end products and tooling components, no matter how complex their designs. Some of its other benefits include:

1. Precision and accuracy;

2. Metal 3D prints have higher degrees of tolerance;

3. Extensive applications across various industries such as aerospace, defence, automotive healthcare etc.

Understanding the technology

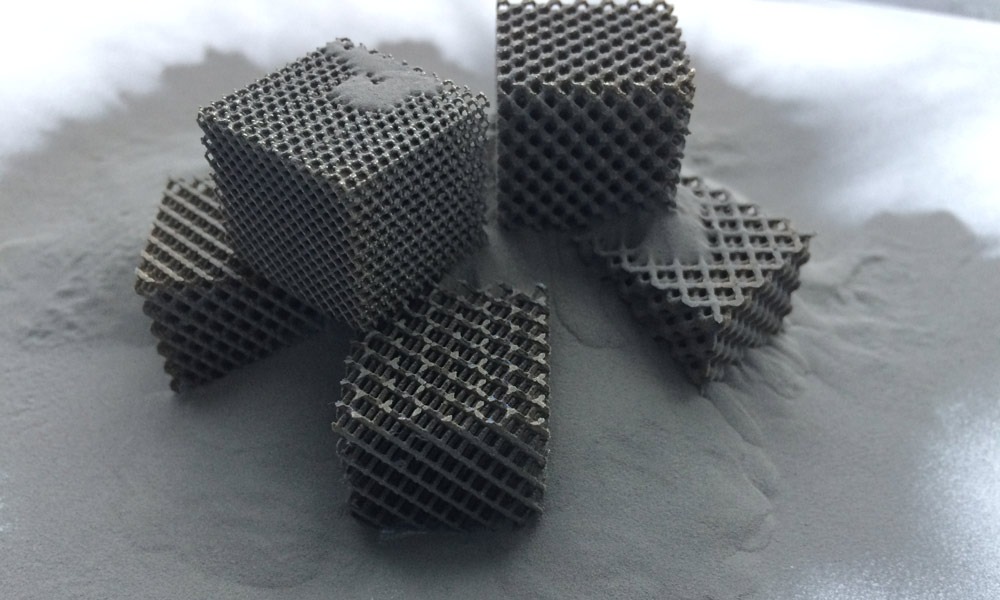

Metal 3D printing works on the basis of laser technology, using metals in their powder form. Printers designed for 3D metal printing are categorized into one of four broad groups of technology, viz. powder bed fusion, binder jetting, direct energy deposition and material extrusion. We discuss each separately.

1. Metal Powder Bed Fusion: This technology incorporates direct metal laser sintering or DMLS, selective laser melting or SLM and electron beam melting or EBM. PBF printed metal parts are stress-free which make them suitable for applications in demanding environs of aerospace and automotive.

2. Metal Binder Jetting: This form of metal 3D printing can operate smoothly even at room temperatures, thus nullifying the effects of warping. Supports are also not required because of this property. If your requirement is a small-batch run or you need a solution for meeting demands for replacement parts, then metal binder jetting technology is your answer.

3. Direct Energy Deposition: Also known as LENS or laser engineered net shaping, as well as DMD or direct metal deposition printing, this type of metal printings makes use of metal wires or powder, which are then melted using a plasma arc, laser, or electron beam. The most common applications of this technology are in the domain of repairing or improving existing designs on components.

4. Metal Material Extrusion: Originally designed with the intended purpose of making metal 3D printing more accessible and cheaper for small and medium businesses, this technology is largely used in small production batches or to make design modification. Metal filaments are used in this process.

Other types of 3D metal printing

· Joule Printing: This is similar to DED in that metal wires are melted. However, the process of melting differs in this case where a current is run through the wires to melt them. The process proves to be quicker than DED.

· Electrochemical Deposition: Ongoing research has brought to light a nano-scale metal 3D printer capable of printing objects smaller than a strand of human hair.

· DLP metal printing: This process is very similar to metal material extrusion in that metal powder is mixed with the photopolymer resin.

· Cold Spray Metal Printing: Originally employed by NASA in their space research, this is currently the fastest 3D metal printing technology available in the world.

· Ultrasonic Consolidation: Also called Ultrasonic Additive Manufacturing (UAM), this type of metal 3D printing uses sound technology to bind thin layers of metal foil.

Advantages of metal 3D printing

· The increasing research and continuous improvements in the technologies of metal 3D printing is gradually making the transition from small batch to mass production possible.

· You can expect to obtain superior quality end products and tooling components but at much cheaper prices than in conventional manufacturing techniques.

· Where traditional manufacturing fails, metal 3D printing can produce highly complex geometries of components.

· Lightweight metal 3D printed parts are all the rage especially in the aerospace, defence and automotive industries.

· Metal 3D printing offers a wide array of options in print materials, including those that are impossible to process using conventional techniques.