Leading the Charge: Vital Participants Innovating the Injection Molding Industry

In the ever-evolving landscape of manufacturing, injection molding is highlighted as a cornerstone technology, enabling the production of a myriad of high-quality components across diverse industries. As the demand for increasingly intricate designs and sustainable practices keeps to grow, leading innovators are taking action to revolutionize this critical process. From advanced materials to cutting-edge machinery, these key players are not only enhancing productivity but also paving the way for a greener future in production.

Injectors and injectors are harnessing the power of artificial intelligence, automation, and IoT to optimize operations and minimize waste. By pushing the limits of what injection molding machines can attain, these pioneers are setting new standards for precision and speed. The advancements driven by these industry leaders are changing how products are made, ensuring that companies can meet the challenges of today while getting ready for the needs of tomorrow.

Cutting-edge Methods in Plastic Molding

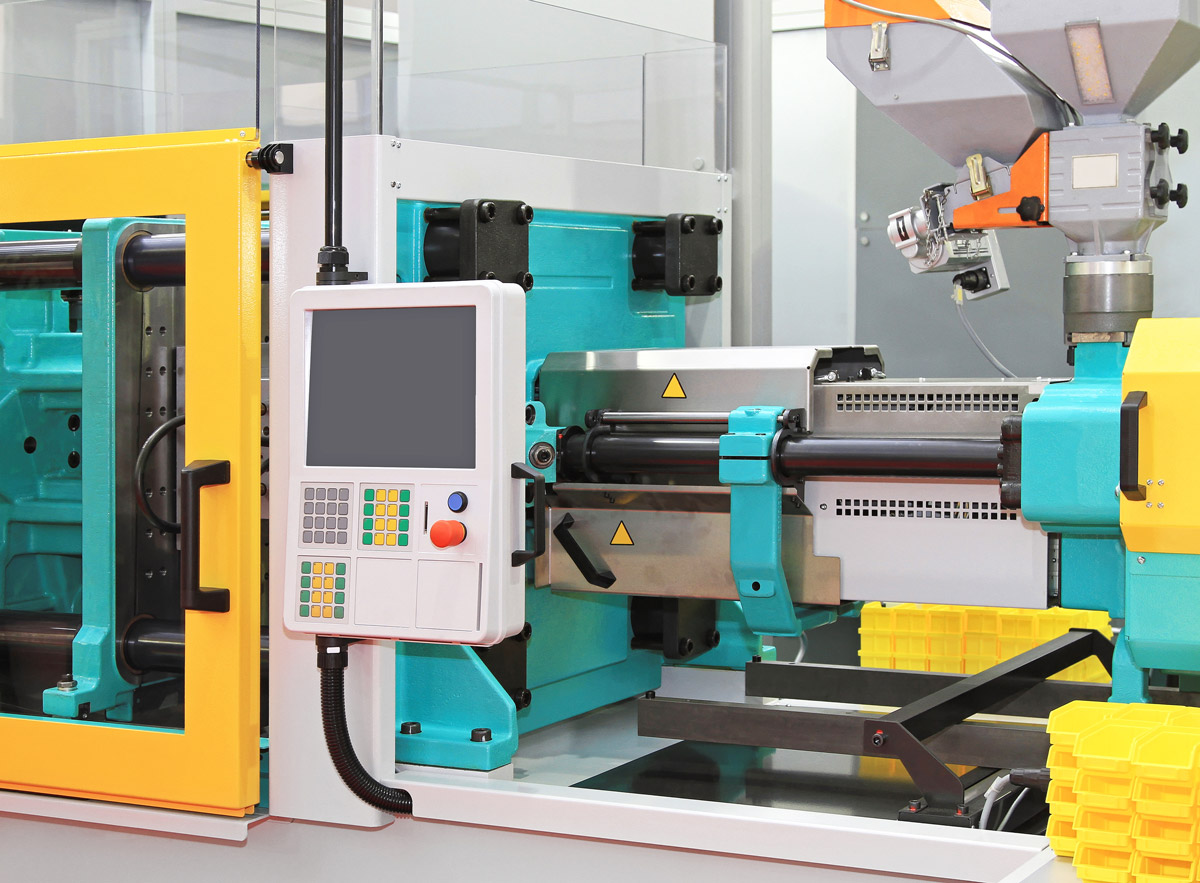

The realm of injection forming is undergoing a significant change, driven by the adoption of modern technologies that enhance productivity and precision. One of the most notable innovations is the implementation of automation and robotics. Automated systems streamline the production workflow by reducing human error, increasing speed, and facilitating complex operations that were once demanding on manpower. High-speed robots can perform tasks such as loading materials, removing parts, and performing quality checks, making the operation more effective and dependable.

Another transformative development is the emergence of intelligent injection molding machines equipped with IoT capabilities. These machines are capable of real-time oversight and operational analytics, enabling manufacturers to collect essential data and optimize their processes. By connecting machines to the web, operators can monitor production metrics, forecast maintenance needs, and reduce downtime. This interconnectivity not only enhances productivity but also drives considerable cost savings in the long run.

Additionally, the innovation of materials used in injection molding has opened new avenues for product development. Biodegradable plastics and advanced composites are becoming increasingly popular, catering to both environmental concerns and the need for high-performance materials. These new materials deliver enhanced strength, lighter weights, and enhanced recyclability, allowing manufacturers to develop products that satisfy modern sustainability standards while maintaining the integrity required for various uses.

Leading Companies Transforming the Industry

In the realm of plastic injection technologies, a few organizations have risen as pioneers, steadily redefining the norms of the industry. One such company is a leading manufacturer, famous for its state-of-the-art plastic injection machinery and commitment to eco-friendliness. Their electric-powered and dual machines are created not only for performance but also to minimize energy use, making them a favorite among environmentally conscious companies.

Another critical player is Engel, which has been at the forefront of integrating automation with traditional injection molding processes. Y company's smart solutions boost production capabilities and versatility, allowing producers to respond swiftly to market demands. Their focus on intelligent manufacturing technologies, including Industry 4.0 concepts, places them as a key driver in the progression of plastic manufacturing.

Finally, KraussMaffei is notable with its innovative approach to material handling and process optimization. By developing systems that incorporate real-time tracking and analytics, KraussMaffei assists producers achieve increased exactness and reliability in their goods. These advancements not only enhance output quality but also enhance overall production efficiency, establishing Z company's role as a transformative player in the molding industry.

Future Trends in Injection Molding

As the demand for more sustainable manufacturing processes grows, the injection molding field is witnessing a significant shift towards sustainable materials and practices. Companies are investing in bioplastics and repurposed materials to create goods with a lower environmental impact. This change not only addresses consumer preferences for more sustainable items but also meets more stringent regulations aimed at reducing plastic waste. In the coming years, we can expect to see further innovations in biodegradable materials that can be smoothly integrated into existing injection molding setups.

Advancements in technology are playing a key role in the future of injection molding. The adoption of 4th industrial revolution concepts, such as the Internet of Things and automated systems, is transforming traditional manufacturing processes. Smart injection molder s equipped with monitoring devices can track and enhance production in real-time, leading to increased efficiency and lower waste. The implementation of artificial intelligence in ML algorithms is being investigated for predictive maintenance, ensuring that machinery operates at optimal performance and minimizing breakdown time.

In conclusion, the personalization of products is becoming more important in the injection molding sector. With the rise of custom consumer products, manufacturers are looking to adopt more flexible production methods, such as injection molding of limited quantities with high precision. This movement pushes manufacturers to rethink their creative and production strategies, allowing for faster adaptations to market demands and leading to a more agile manufacturing ecosystem. As these trends continue to progress, the injection molding industry will remain at the cutting edge of advancement, facing the obstacles of the future head-on.