Investment Castings - Knowing Its Processes and Applications

Vaishali AegisLost-wax casting, also known as investment casting, is found in all ancient cultures and is believed to be around 500 years old. In the past, beeswax was used to fill in a pattern, and then was filled with the casting material that gave the metal components, which were complemented by a high level of repeatability, accuracy, and strength. There has been a change in the forming of many important materials, such as making use of beeswax, but there are still many primitives within the forming of materials today. As copper casting has clearly proved to be such an ancient and valuable method, this type of technique should continue to be a standard today, especially for things like paper plates.

What is Casting for Investment?

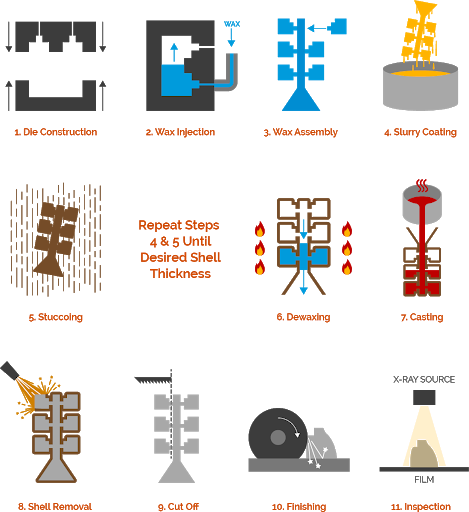

Investment Casting alludes to the pottery made to create a packaging for liquid metal to be poured around the wax designs. They are dissolved onto a door framework once the wax designs are made, dunked into slurry and sand to shape a layered packaging, at that point subbed with softened metals, for example, treated steel, aluminum, and significantly more. The Investment Casting Manufacturers In India help the customers in investment casting so that they are able to make superior purchasing decisions. Some of them are Wax Injection, Ceramic Shell Building, Assembly of Wax Tree, Conventional Casting, De-wax, Cut-off of parts, Finished Metal Investment Castings and so on.

How are Investment Castings constructed?

The development of investment castings involves the creation of an original wax pattern, the coating of the image with plaster and the construction of consecutive layers until the model is enveloped by a strong shell. Molten steel, stainless steel or bronze will be poured into the mold after the wax has been melted, producing a perfect duplicate of the original wax pattern. Compared to machining apart, undercuts, high definition, complex detail and a smooth surface finish can be economically offered by investment casting manufacturers in India.

Benefits of Investment Casting:

• It is possible to obtain very close tolerances and performance surface finish.

• It is possible to have complex shapes complicated by any other technique.

• No flash lines or dividing lines available

• Investment casting can cast almost any metal by

• With no machining required, ready for use.

The technology behind investment castings

With the production of the so-called master pattern, the entire process begins. Wax, clay, steel, plastic or wood can be used by the artist to create the original pattern. After that, he will be prepared to produce the mold or die for the master. Made of metal, steel or metal, this one is made.

Once the moulds have been completed, the wax patterns will also be produced. This kind of pattern is not simply made of wax. In the process, plastic or frozen mercury are also being considered. Patterns are done in two ways: first, where wax is poured into the mold and swished to produce even coating; and the other, until it is cool and the ideal thickness is gotten, is by leaving the filled form. At the point when the wax designs are taken out from the form, it is important to collect them.

An critical area, of course, is investment. The stainless mould is referred to as the investment itself. This is accomplished by repeating three significant steps in the process, namely coating, then hardening and puts a lot. Next, dewaxing or drying comes after investment. This is generally done over a period of between 16 and 48 hours. In the whole procedure, preheating, spilling, and abolishment are also critical factors.

Investment casting manufacturers in India has wide experience in the investment casting process with commitment to incessant development and mechanization, well industrialized workings to achieve high consistency. They are with the customers all the way, from the initial phases of design to assure your parts are of larger quality and modest price.

Common applications for an investment cast

The manufacturers are pleased to create multipart investment cast parts with superior surface finishes at the industries quickest lead-times for the following markets:

• Aerospace

• Defense

• Medical

• Electronics

• Automotive

• Gas and Oil

• Agriculture