Injection Molding Explained: A Quick Guide

Injection molding is key in making many plastic parts today. It lets makers create lots of identical pieces quickly and precisely. It's important in making stuff for cars, health care, and everyday products.

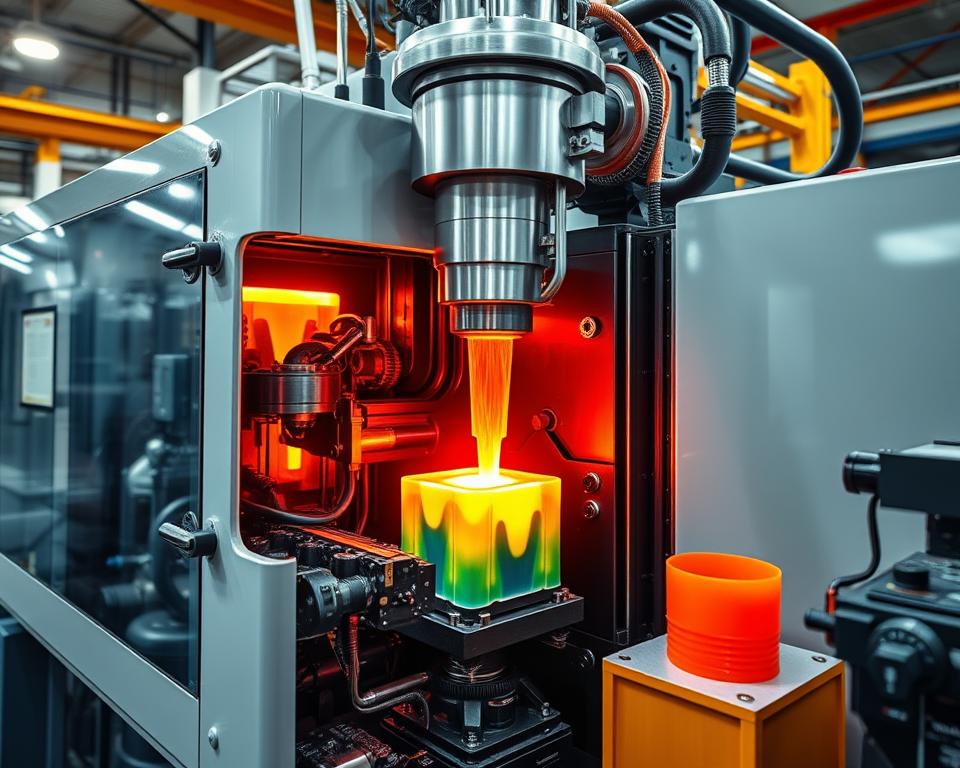

At the heart of this are machines that shape hot plastic perfectly. Knowing how injection molding works shows us its big role. It helps make things cost-effective and consistent.

Key Takeaways

- Injection molding is essential for producing identical plastic parts efficiently.

- It's widely used in industries like automotive, medical, and consumer products.

- This manufacturing process is known for its precision and efficiency.

- Injection molding machines are crucial for shaping molten plastic.

- The technique supports the mass production of complex forms.

Understanding the Injection Molding Process

The injection molding process makes parts by putting molten stuff into a mold. We'll look at the main parts and steps of this process here. We'll also learn important terms. This will help you understand how to make injection molds better. It will help you make things quicker.

The Basics of Injection Molding

Many parts work together in injection molding to make detailed plastic products. Here are the main parts:

- Injection unit - It melts plastic and puts it into the mold.

- Clamping unit - It keeps the molds shut tight during the process.

- Mold design - It's the plan for the product. It affects how well it's made.

Step-by-Step Injection Molding Procedure

Here are the steps in an injection molding cycle:

- Mold Closing - The clamping unit locks the mold halves.

- Plastic Injection - The injection unit fills the mold with plastic.

- Cooling - The plastic gets hard in the mold.

- Mold Opening - The clamping unit opens the mold.

- Part Ejection - The part is taken out of the mold. This finishes the cycle.

Common Terminology in Injection Molding

Knowing these terms is important for understanding how injection molding works:

- Mold Cavity - Where the plastic goes in the mold.

- Runner System - Paths that lead plastic to the mold cavity.

- Gate - Where plastic enters the mold from the paths.

- Resin - The plastic used in the process.

- Shot Size - How much plastic is put into the mold each time.

Knowing about injection molding helps make manufacturing better and quicker.

Materials Used in Injection Molding

Injection molding is a way to make things with a lot of different materials. Picking the right resin makes the final product good and helps the planet. It's important to know which polymers to use.

Thermoplastics vs. Thermosetting Plastics

There are two big groups of polymers in molding: thermoplastics and thermosetting plastics. Thermoplastics can be melted down and reshaped. This means they can be used again, which is good for the Earth.

Thermosetting plastics, however, change when they're heated. They become hard and can't change shape anymore. They’re great for things that need to withstand a lot of heat or force. But, they can't be recycled easily.

Choosing the Right Material

When picking a resin, think about what the part will do, its design, and what properties it needs. For example, polycarbonate is strong and clear, making it perfect for things you need to see through. Nylon is tough and resists wear, which is good for parts that move.

Resistance to heat and chemicals matters too. Fluoropolymers are chosen in the chemical industry for their resistance. And when it comes to cost, ABS is a go-to for balancing price and performance.

Recycling and Sustainability in Injection Molding

The impact on the environment is getting more attention in the molding world. Working on recycling and making plastics that can break down naturally is moving us towards greener manufacturing.

Using recycled stuff in new products lessens waste and saves resources. Also, choosing better resins means we can make things that are both high-quality and Earth-friendly.

By making smart choices with materials, the molding industry is getting better at helping the planet. This matches up with worldwide goals to protect our environment.

Advantages of Injection Molding for Mass Production

Injection molding is great for making lots of things at once. It makes things cheaper when you make more. Making lots of things spreads out start-up costs over many items. This is perfect for items we use every day and for car parts.

Injection molding is also very flexible. It can make parts that are really detailed and complex. This is super important for medical devices, electronics, and stuff we use at home. It makes strong and durable parts with fancy designs, which other methods can't do.

Automation has made injection molding even better. Machines now do a lot of the work, making things faster and cutting costs. They use robots and other cool tech to check quality. This means everything made is top-notch. Manufacturers can depend on this process for lots of high-quality items.