Indicators on Prusa3D - Open-Source 3D printers by Josef Prusa You Need To Know

The Main Principles Of Cults ・ Download for free 3D models for 3D printers

A drawback of wireless is that, because 3D printing files can be approximately 10MB in size, it can take a while to transfer them. Another connection method that we have actually seen is Ethernet, for sharing a printer on a regional network. Numerous printers have SD or micro, SD card slots from which you can load and print 3D item files using the printer's control board and display screen, while others have ports for USB flash drives.

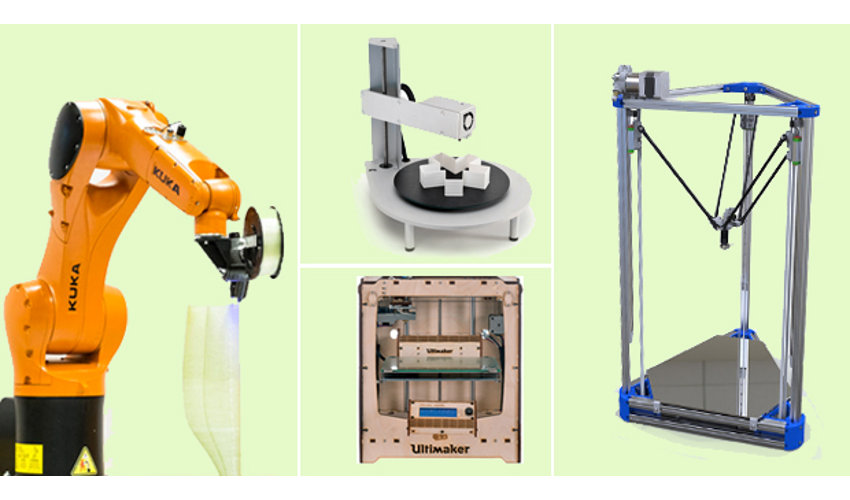

The 4 Types of FFF / FDM 3D Printer Explained (Cartesian, Delta, Polar) - 3Dnatives

The 4 Types of FFF / FDM 3D Printer Explained (Cartesian, Delta, Polar) - 3DnativesThe drawback is that it adds an extra action, that of transferring the files to your card. Generally, wireless, SD card, or thumb-drive connection is provided in addition to the standard USB cable television, although a few designs leave out the latter. What Software application Do You Need? Today's 3D printers feature a suite of softwarealmost constantly Windows-compatible, and frequently for mac, OS and Linux as wellon a disk or as a download.

These parts were originated from the Associate, Rap open-source project, which spurred the development of low-cost 3D printers. Today, printer producers have actually incorporated these programs into seamless, easy to use bundles, lots of structure on the Cura open-source platform. 3DPrinterBusiness allow you to utilize different element programs, if you prefer.

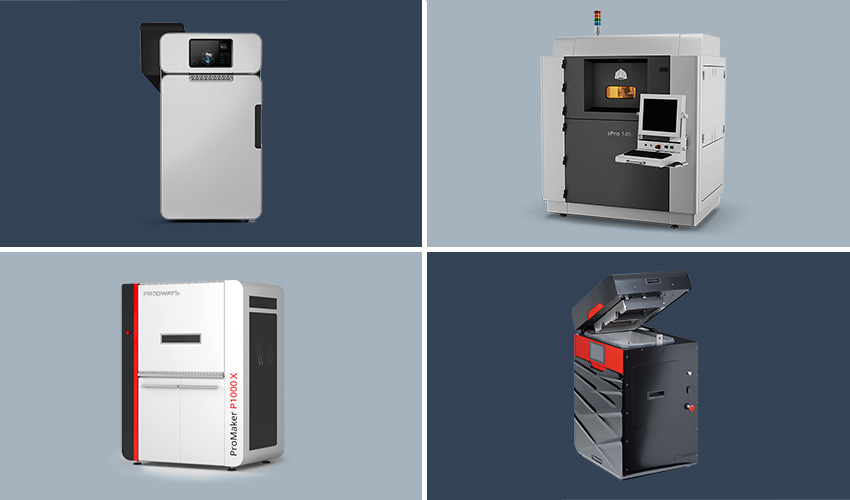

The different SLS 3D printers on the market - 3Dnatives

The different SLS 3D printers on the market - 3DnativesThe Definitive Guide to Ultimate 3D Printing Store I 3D Printers I 3D Printer Parts

They cover a vast array in price, features, and printing methods, but they all represent quality. For additional information on how 3D printing works, our subject primer is a good place to start. Likewise, be sure to check out our roundup of the best total printers.

Selective laser sintering (SLS) 3D printers utilize a high-power laser to sinter small particles of polymer powder into a strong structure. The unfused powder supports the part throughout printing and gets rid of the requirement for devoted assistance structures. This makes SLS ideal for complex geometries, including interior features, damages, thin walls, and negative functions.

The most typical product for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical residential or commercial properties. Nylon is light-weight, strong, and flexible, as well as steady versus effect, chemicals, heat, UV light, water, and dirt. The mix of low expense per part, high productivity, and established materials make SLS a popular choice among engineers for practical prototyping, and a cost-efficient alternative to injection molding for limited-run or bridge production.

Best 3D Printers for Beginners in 2021 - All3DP

Best 3D Printers for Beginners in 2021 - All3DP8 Easy Facts About Prototyping, Fabrication Products - 3D Printers - DigiKey Described

Envision, style, develop, and manufacture the future with 3D printing and additive manufacturing.