In what way Vacuum-based Electrical Interfaces Power Contemporary Innovations

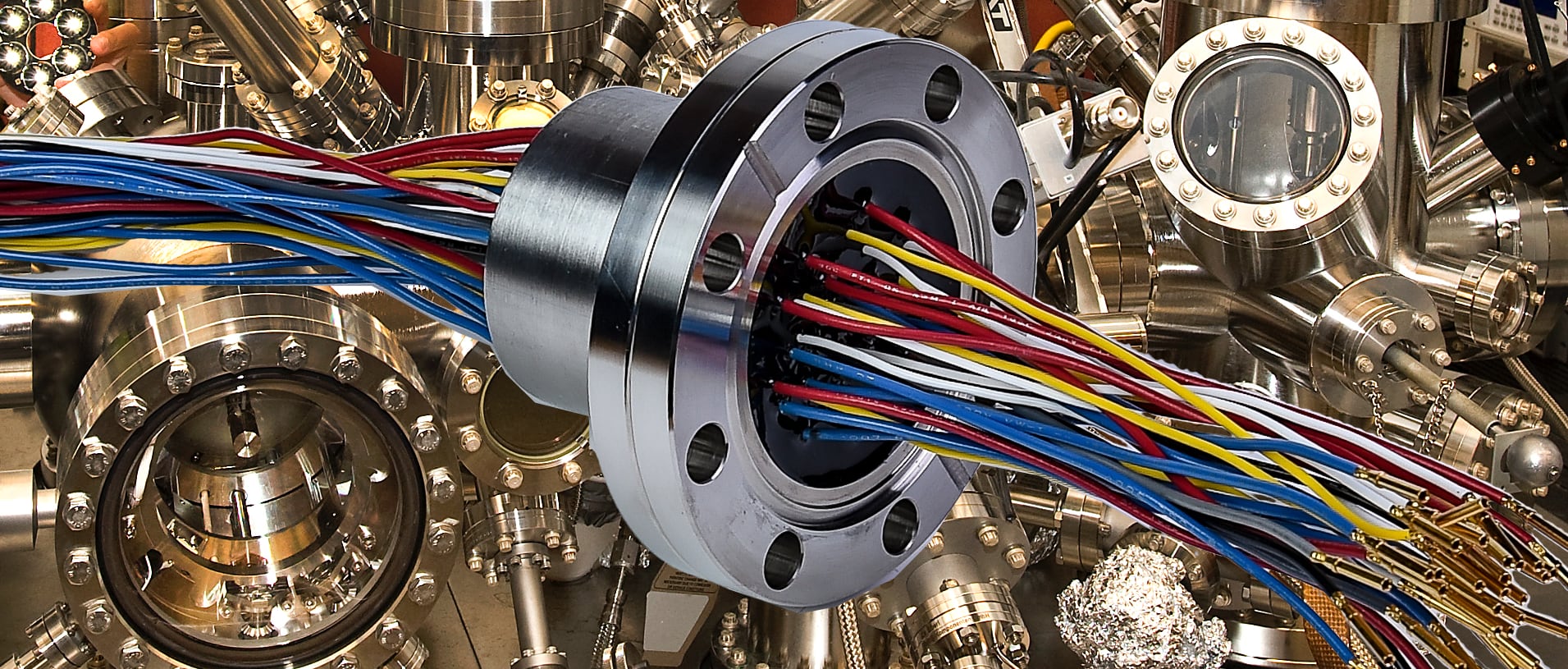

In the realm of contemporary tech, the seamless transfer of electrical signals is crucial for the effective operation of a wide array of equipment. One vital component that often goes overlooked but plays a critical role in this exchange is the vacuum electronic feedthrough. These custom components act as gateways, allowing electrical connections to traverse vacuum-sealed environments without compromising the purity of the vacuum. This capability is particularly important in areas such as semiconductor manufacturing, subatomic physics, and intense laser uses, where preserving a controlled environment is critical for efficacy and safety.

Sealed feedthroughs enable the transmission of energy and signals, functioning as the link between the outside world and extremely sensitive machinery housed within vacuum chambers. By ensuring that power connections remain sealed from atmospheric contamination, they enable cutting-edge technologies to operate effectively. As sectors continue to push the limits of research and innovation, understanding the significance of these feedthroughs becomes ever more critical in appreciating how they play a role to the advancements shaping our future.

Understanding Low-Pressure Electric Connectors

High-Vacuum electric feedthroughs are vital components which enable the passage of electric currents or energy through a sealed barrier. Such connectors are engineered to preserve the integrity of the vacuum environment in situations where exposure to the atmosphere could jeopardize device performance. By providing a sealed route for electric connectivity, they allow for the reliable operation of devices in vacuum conditions, which remains crucial in various areas including semiconductor manufacturing, scientific experiments, and aerospace.

The construction of vacuum electric connectors often includes materials which can withstand elevated heat and are resistant to the damaging impact of the environment. Typical materials include ceramic materials and metals, which provide strength and electrical dependability. The connectors are often airtight to avoid any gas escapes that could damage the seal. The configuration must also accommodate the appropriate electric specifications, such as electric potential and amperage levels, to ensure they can manage the necessary operational demands.

Uses of sealed connectors are diverse, spanning across industries that rely on high-vacuum methods. They are common in particle accelerators, microscopy, and vacuum ovens, where they play a key function in powering and controlling various components without breaking the vacuum. As advancements continues to advance, the demand for efficient and reliable sealed feedthroughs grows, making them critical in modern engineering infrastructure.

Applications in Modern Technology

Vacuum electric feedthroughs are vital parts in multiple modern fields, enabling optimal functioning in environments that require controlled atmospheres. In the semiconductor industry, these connectors facilitate the connection of electrical signals and power to machinery situated within vacuum enclosures. This is crucial for operations such as lithography, etching, and deposition, where any contamination would obstruct the quality of the electronic components being manufactured.

Additionally important use of vacuum connectors is in research research, particularly in areas like particle physics and material science. High-energy experiments often take place in vacuum environments to minimize disruption from air particles. These connectors provide stable connections for sensors, devices, and other equipment, guaranteeing that data can be sent without disruption. Their ability to maintain a complete closure within high-vacuum settings makes them invaluable in these environments.

In addition, vacuum electrical connectors play a pivotal role in the aerospace and astronautics exploration industries. They are used in satellite systems and spacecraft to connect electrical components that need to function in the vacuum of outer space. By allowing for energy connections while maintaining the integrity of the vacuum, these connectors help secure the functionality and durability of essential systems in challenging conditions.

Upcoming Innovations and Developments

As tech continues to advance, the demand for highly efficient and dependable vacuum feedthroughs is on the rise. Researchers are exploring the use of cutting-edge materials that could boost the thermal & electrical properties of the feedthroughs, which help to improve performance in adverse environments. These developments are expected to lead to feedthroughs that offer better durability and corrosion resistance, which is particularly important in industries like aviation and microchip manufacturing.

Moreover, the integration of advanced technology into vacuum feedthroughs is on the horizon. This includes the incorporation of sensors and monitoring systems that allow for real-time data collection on the performance and reliability of the feedthroughs. Such innovations will facilitate proactive maintenance strategies and help in preventing failures, leading to increased operational efficiency and reduced service interruption.

Lastly, sustainable manufacturing practices are likely to influence the production of vacuum feedthroughs . As industries aim to minimize their carbon footprint, the focus will shift towards utilizing reusable materials and environmentally friendly processes in the production of these components. This trend reflects a broader commitment to sustainability across technology sectors, ensuring that the progress of vacuum feedthroughs aligns with global efforts to create a sustainable future.